Maintenance1132−2/A1

RT-flex58T-E

Winterthur Gas & Diesel Ltd.

8/ 14

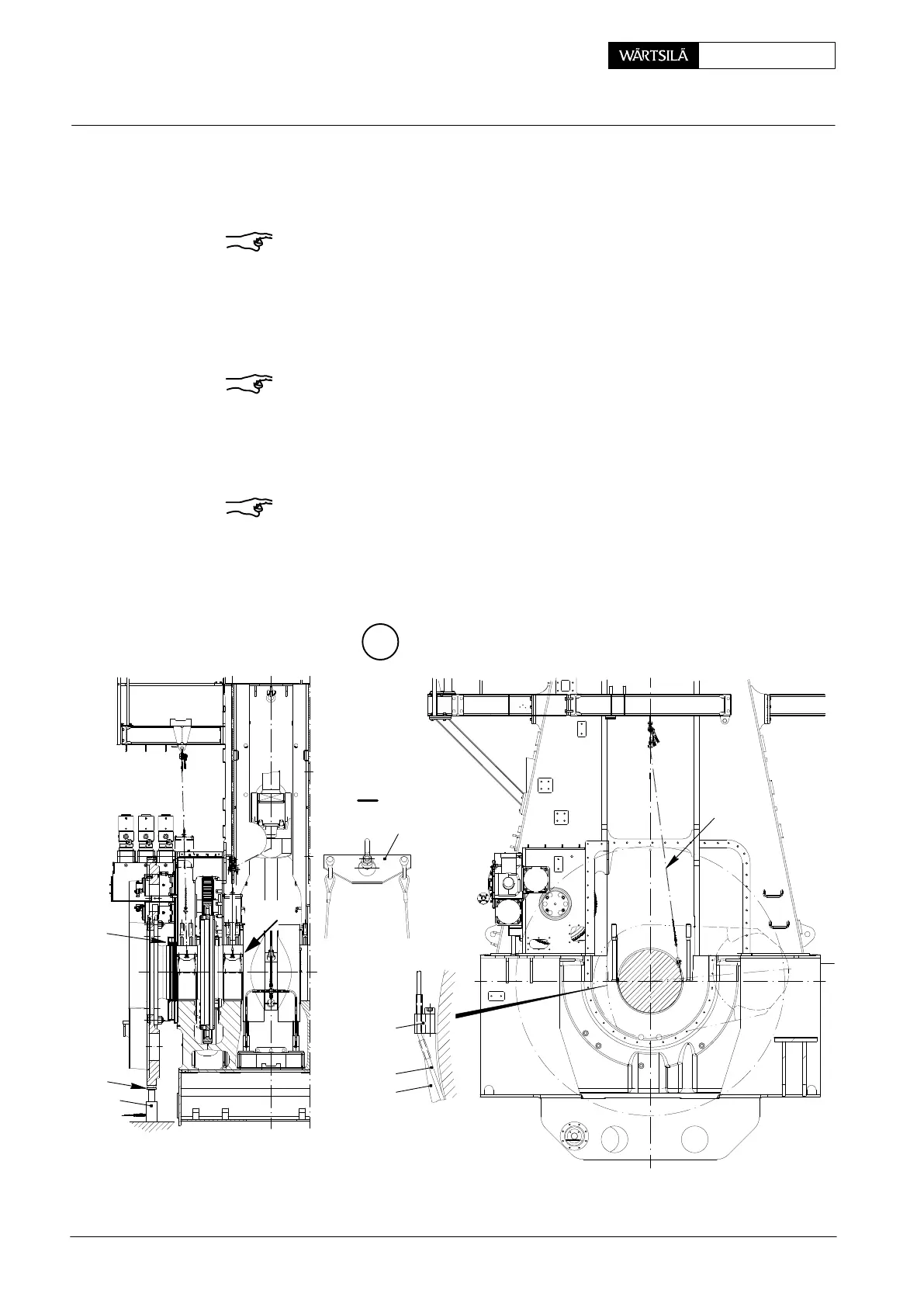

4.4 Turning out main bearing shell No. 1

D Crankshaft lifted up by approx. 0.2 mm (see paragraphs 5.1 and 5.2).

Remark: Turning-out device 94118 must only be fitted to bearing shell No. 1

instead of turning-out device 94118A, which is provided for all other bearing shells.

⇒ Fasten manual ratchet ’H1’ with rope 94120B to gallery support.

⇒ Fasten turning-out device 94118 to bearing shell 3 using screwdriver 94129,

lead ropes ’a’ along the lateral edges of the bearing shell 3 to the other side

and connect them with lifting yoke 94119.

Remark: By means of a wire attached to the ropes they can be pulled below the

bearing journal to the other side.

⇒ Slowly turn out bearing shell using manual ratchet ’H1’ from the bearing girder

until both ends of the bearing shell are free (no meshing), check!

⇒ Remove lifting yoke.

Remark: If a bearing shell jams during turning out, lifting yoke 94119 must be fas-

tened to the two opposite wire ropes of turning-out device 94118. Subsequently

draw the bearing shell back to the initial position until the bearing shell is freed.

K

II

94119

94120B

H1

94118

H1

WCH01015

II

3

a

PR

PR

94959

Removal and Fitting of a Main Bearing

2013 / V2

Loading...

Loading...