Maintenance

1132−2/A1

RT-flex58T-E

Winterthur Gas & Diesel Ltd.

7/ 14

4.2 Lifting the crankshaft

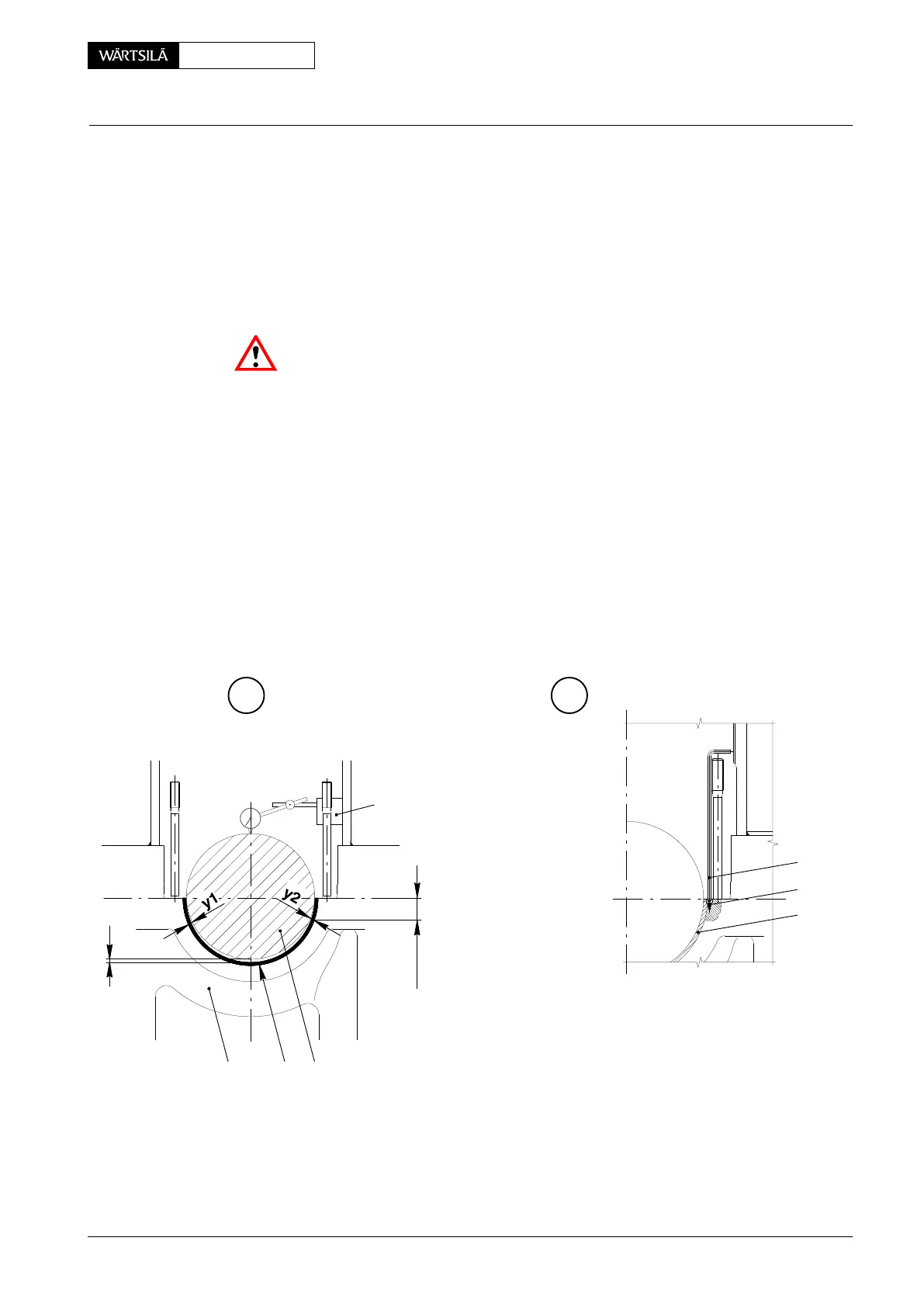

⇒ Measure and note lateral bearing clearances ’y

1

’ and ’y

2

’ between crankshaft

journal 1 and lower bearing shell 3 at about 50 mm below the bearing division.

⇒ Install dial gauge with magnetic base 13 above the crankshaft near the bear-

ing to be removed and set it to zero.

⇒ Actuate HP oil pump 94931 and lift the crankshaft by means of hydraulic jacks

94936 reaching value ’x’ = 0.2 mm (check on dial gauge).

Attention! Lift the crankshaft max. to the point where the neighboring main bear-

ings show no vertical clearance between upper bearing shells and crankshaft.

⇒ Keep pressure in the hydraulic jacks constant.

⇒ Measure again lateral bearing clearances ’y

1

’ and ’y

2

’, and compare the val-

ues with those from the 1

st

measurement as described above.

D If the lateral clearance has changed by more than 0.1 mm due to lifting of the

crankshaft, the latter must be lowered again and the hydraulic jacks be newly

placed in direction of the smaller clearance. Subsequently lift the crankshaft

again.

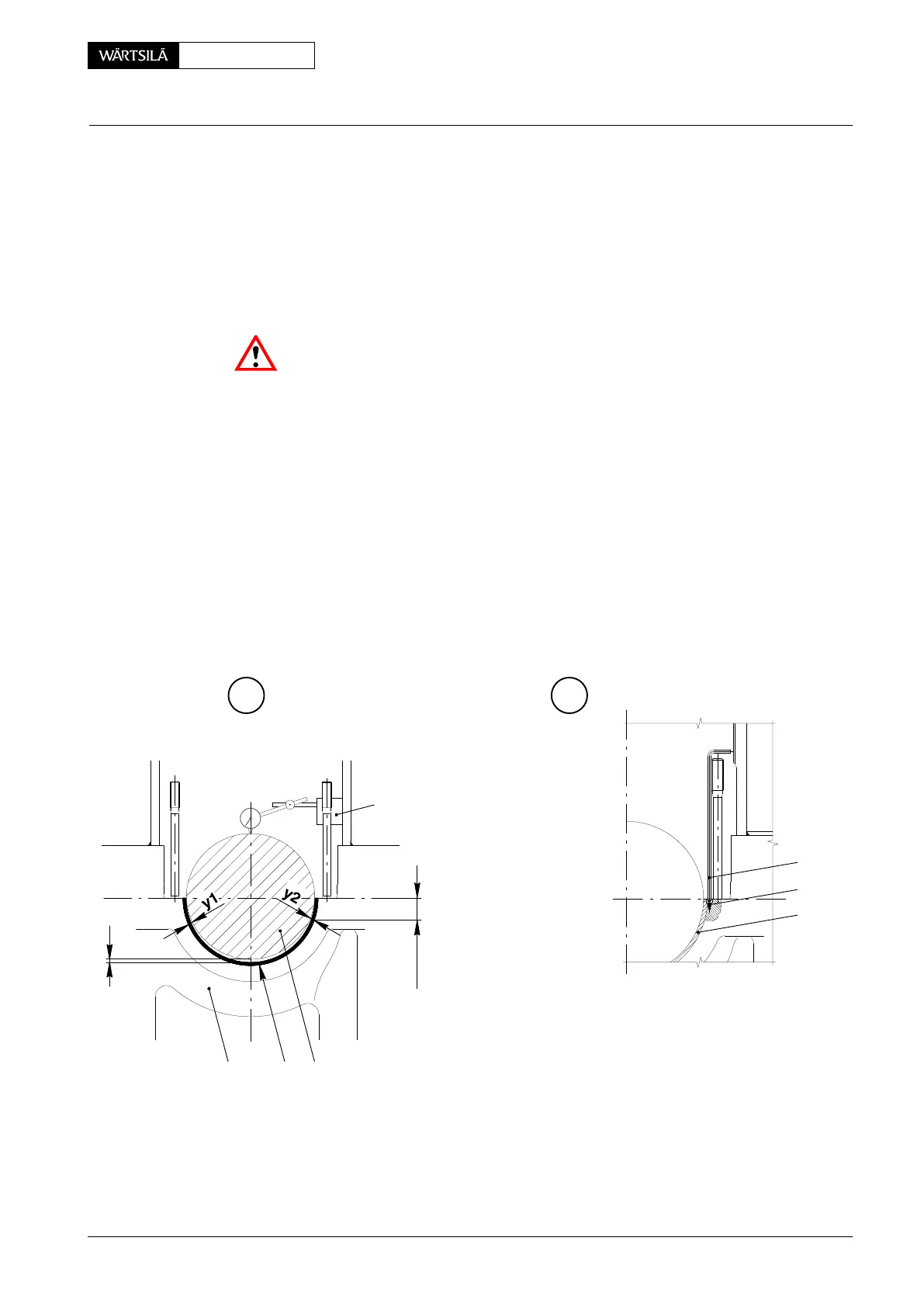

4.3 Loosen the Allen screw

⇒ Loosen and remove both Allen screws 12 with Allen wrench 94128.

I

x

50 mm

009.810/02

13

136

J

94128

12

3

004.211/99

Removal and Fitting of a Main Bearing

2013

Loading...

Loading...