Maintenance1132−2/A1

RT-flex58T-E

Winterthur Gas & Diesel Ltd.

6/ 14

4. Turning out and removal of lower main bearing shell

Attention! Never remove two neighbouring bearing shells at the same time!

The removing procedure for a lower bearing shell 3 (Fig. ’A’) is the same for all main

bearings with the exception of main bearing No. 1 at the driving end.

D For the removal of bearing shells No. 1 and 2 the flywheel must additionally be

pressed up with hydraulic ram 94950. To protect the flywheel toothing, put a

copper or aluminium plate between the ram and the flywheel (Fig. ’K’).

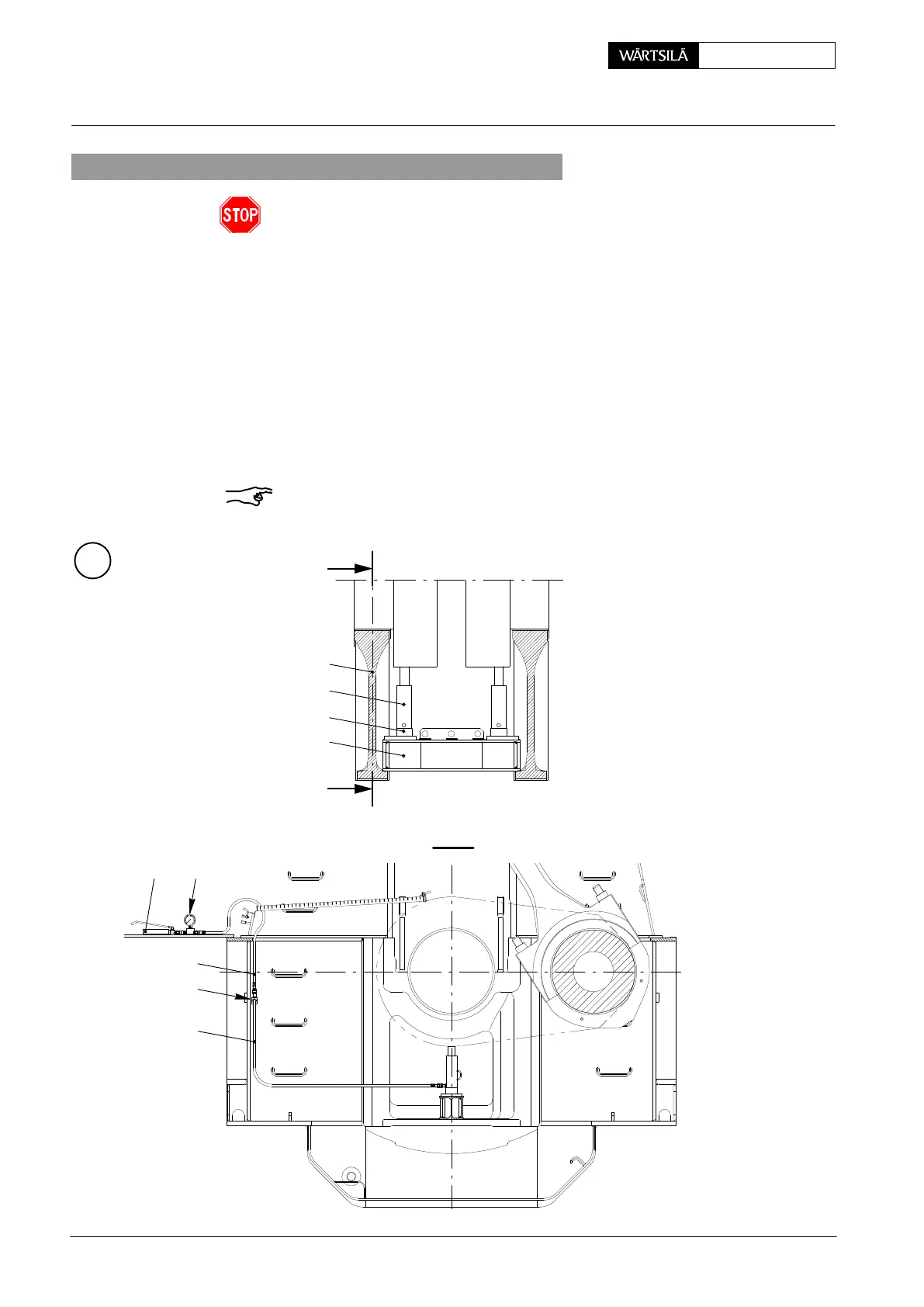

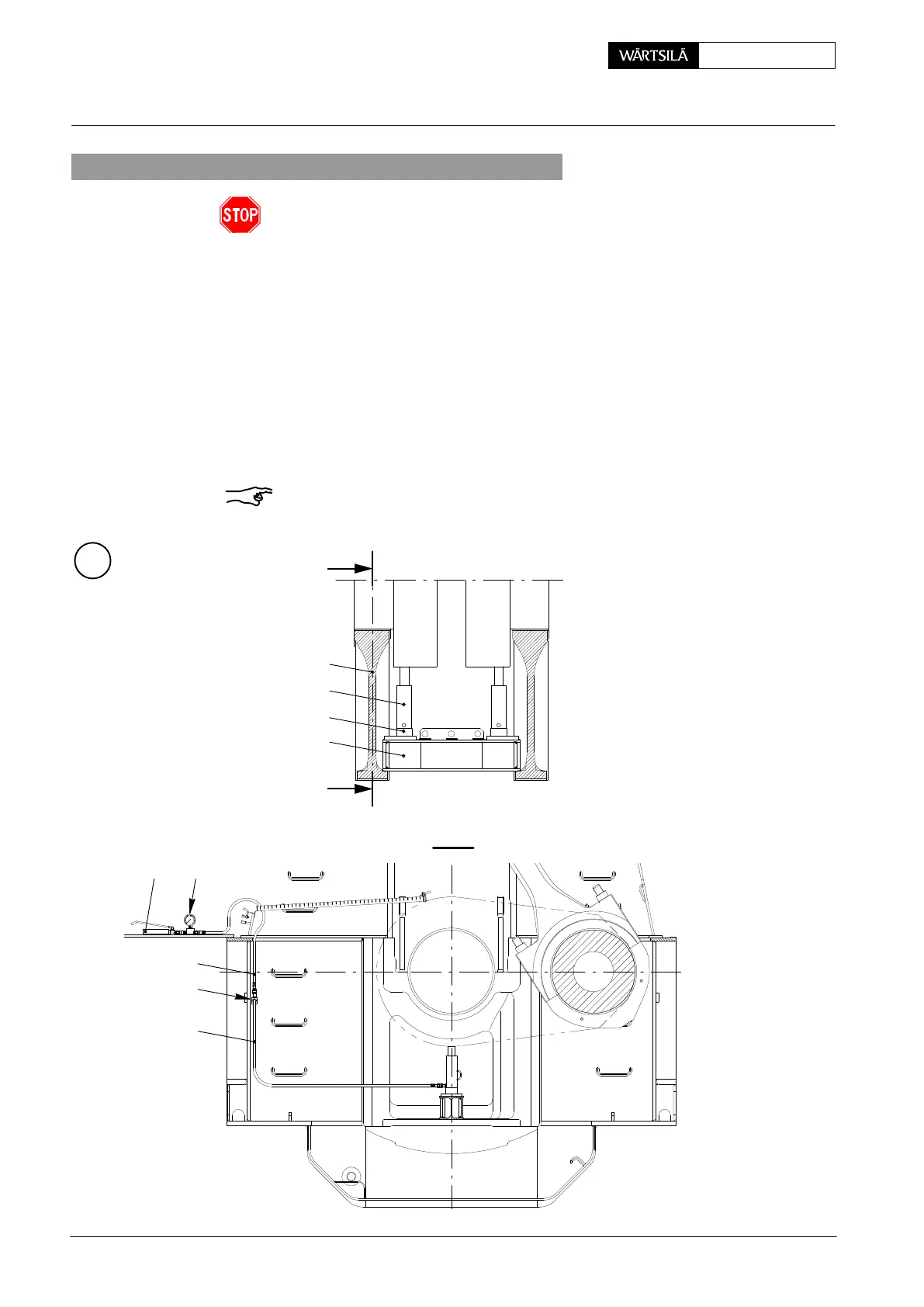

4.1 Placing of hydraulic jacks

⇒ Turn corresponding crank to exhaust side approx. 90_ after T.D.C.

⇒ Put support 94141 on two bearing girders 6 parallel to the engine axis.

⇒ Place hydraulic jacks 94936 on support 94141.

⇒ Connect the hydraulic jacks with HP hoses 94935 and 94935A, as well as

hydr. distributor 94934A to HP oil pump 94931.

Remark: Depending on hydraulic jacks 94936, ground plates 94141A must be

placed onto support 94141 in order to reach the height necessary to lift the crank-

shaft.

H

I - I

9493294931

018.178/09

94935

94935A

94934A

I

I

94936

94141

94141A

6

Removal and Fitting of a Main Bearing

2013

Loading...

Loading...