Maintenance3303−3/A1

RT-flex58T-E

Winterthur Gas & Diesel Ltd.

4/ 6

3. Fitting

Fitting of the bearing shell and bearing cover (see 3303−5) is carried out analo-

gously but in reverse sequence to the removal.

D The running surfaces have to be lavishly smeared with clean bearing oil.

D Tensioning of the elastic studs must be carried out according to 3303−1.

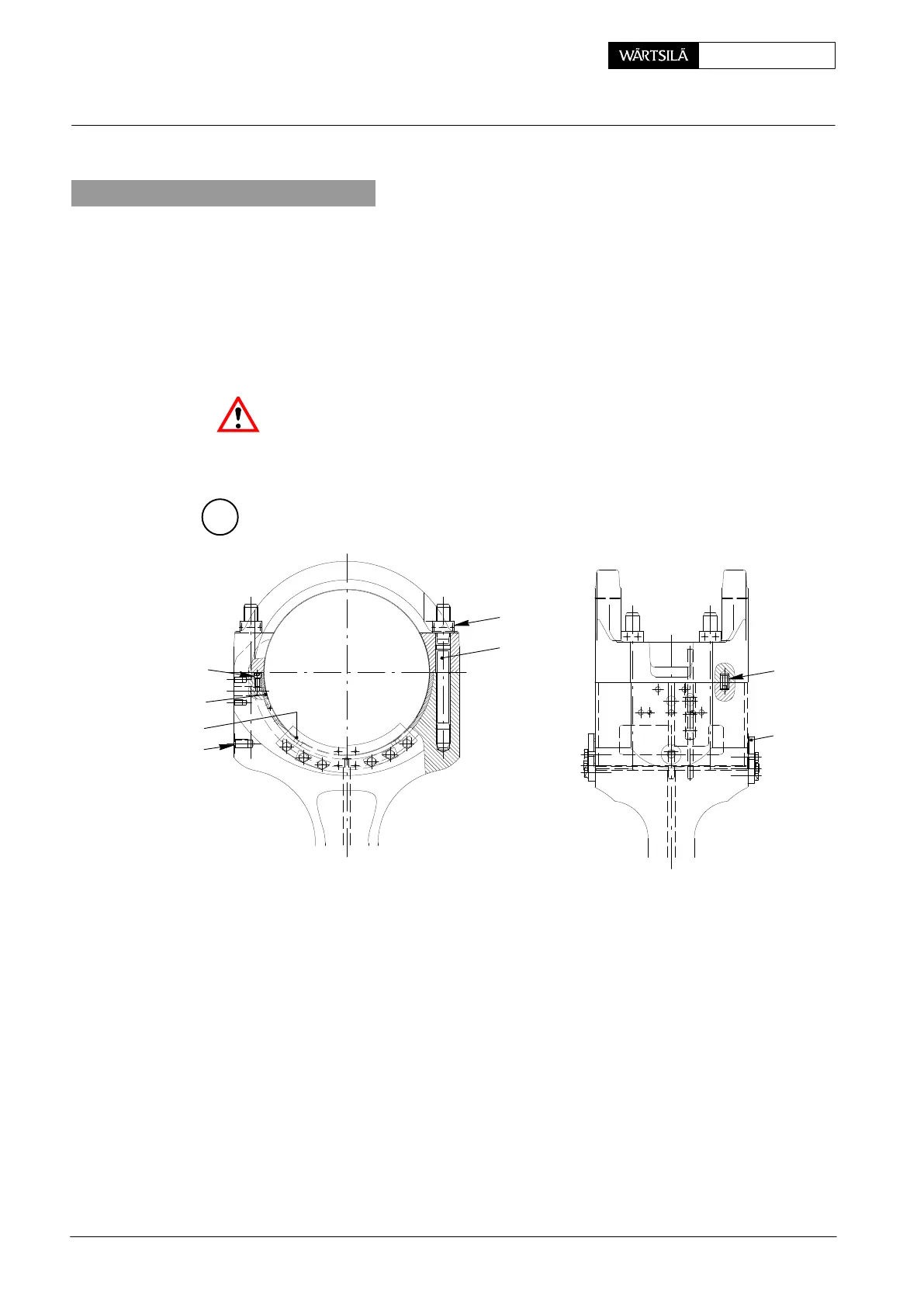

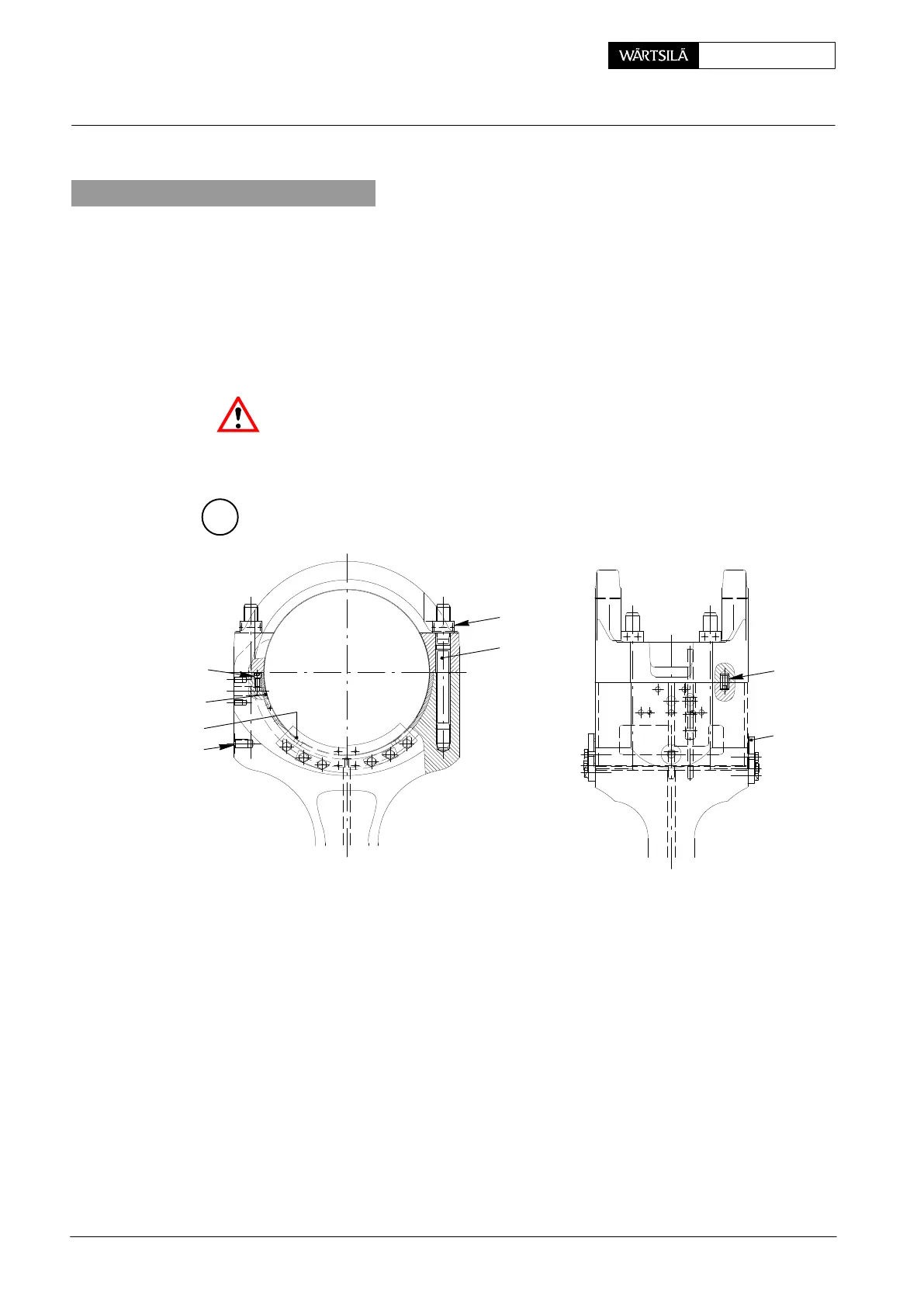

D When fitting the bearing shell, as well as the crosshead pin, pay attention not

to damage the two guide segments 12. The two white metal lined guide seg-

ments are fitted to the front sides of the upper connecting rod head.

Attention! Always fit toggle lever 5 in such a way that its curvature stands up-

wards.

After completing the work all retaining pins 94323 must be removed without fail!

D

2

1

11

12

8

7

12

13

WCH01029

2013

Inspection, Removal and Fitting of Top End Bearing

Loading...

Loading...