18

3064458_201811

Heating circuit

We recommend installing a maintenance valve in both the heating ow and heating return – straight design for surface mounting.

The return line to the appliance must have a dirt trap. A sludge separator with magnetite separator should be

usedtoprotecttheapplianceandthehighefciencypumpfromdirt/sludgeandmagnetite.

Deposits in the heat exchanger may lead to boiling noise, a drop in performance or faults in the appliance.

Please note

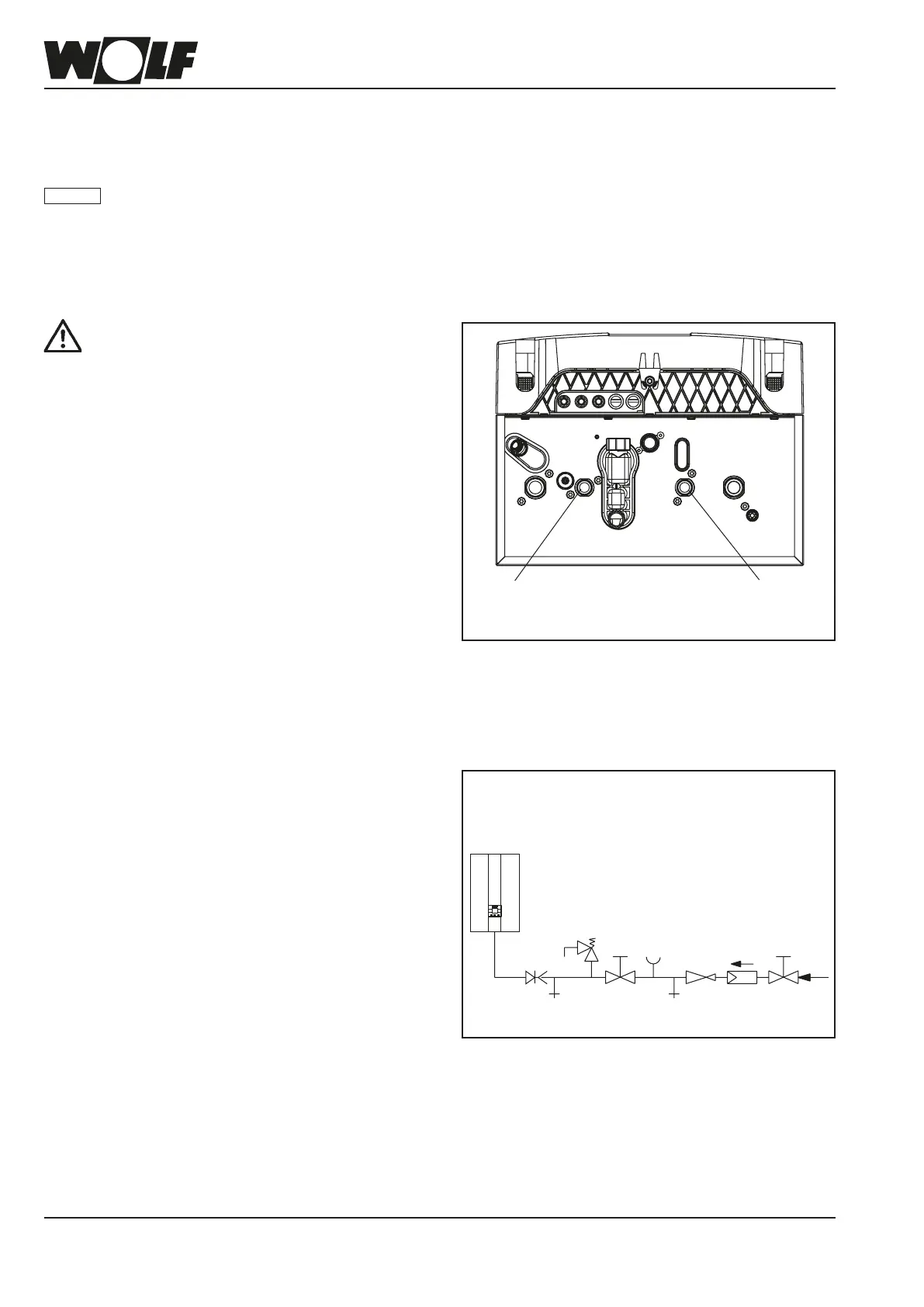

Fig: Drinking water installation

Cold water and DHW connection

A maintenance valve must be installed in the cold water

supply line.

If the cold water supply pressure is above the maximum

permissible operating pressure of 10 bar, install a tested and

certied pressure reducer.

If mixer taps are used, provide a centralised pressure reducer.

Observe the regulations of EN 806 as well as those of your

local water supply utility when connecting cold water and

DHW.Your warranty is void if the installation does not comply

with the illustration shown.

Note: When selecting the installation material for the

system, observe engineering standards and take

into account possible electrochemical processes

(mixed installation).

When installing make sure that, according to

EN 1717, a non return valve is installed in the

drinking water pipeline.

In wall mounted boilers without DHW heating,

install a short circuiting section (accessories)

betweencylinderowandcylinderreturn.

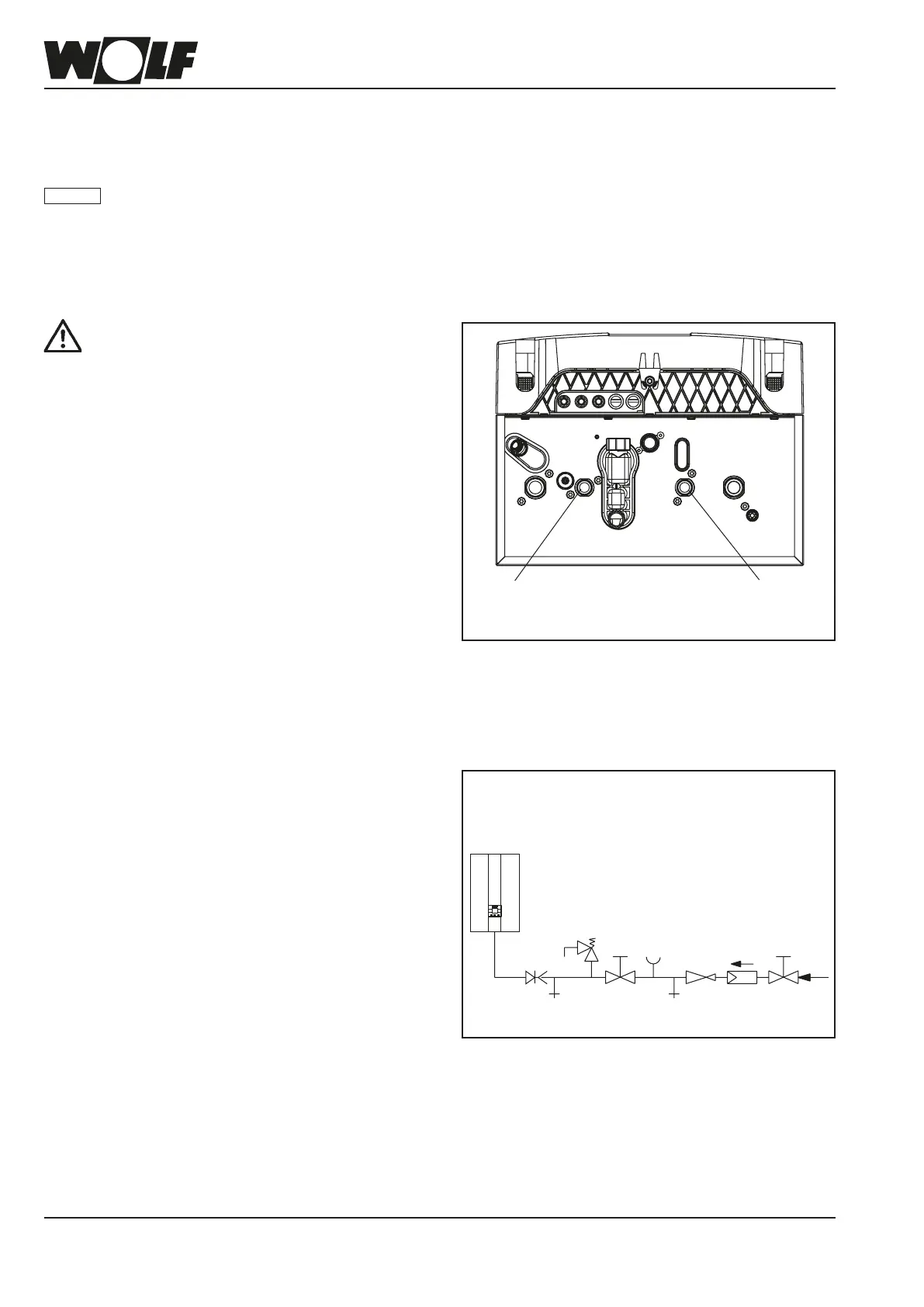

Fig: Cylinder ow / return connections

Cylinder return

G½"

Cylinder ow

G½"

Safety valve

Drain outlet

Shut-off valve

Pressure reducing valve

Shut-off valve

Cold water supply

Drinking water lter

Pressure gauge

connection

Drain outlet

Non return valve

10. Installation

Loading...

Loading...