3064458_201811

57

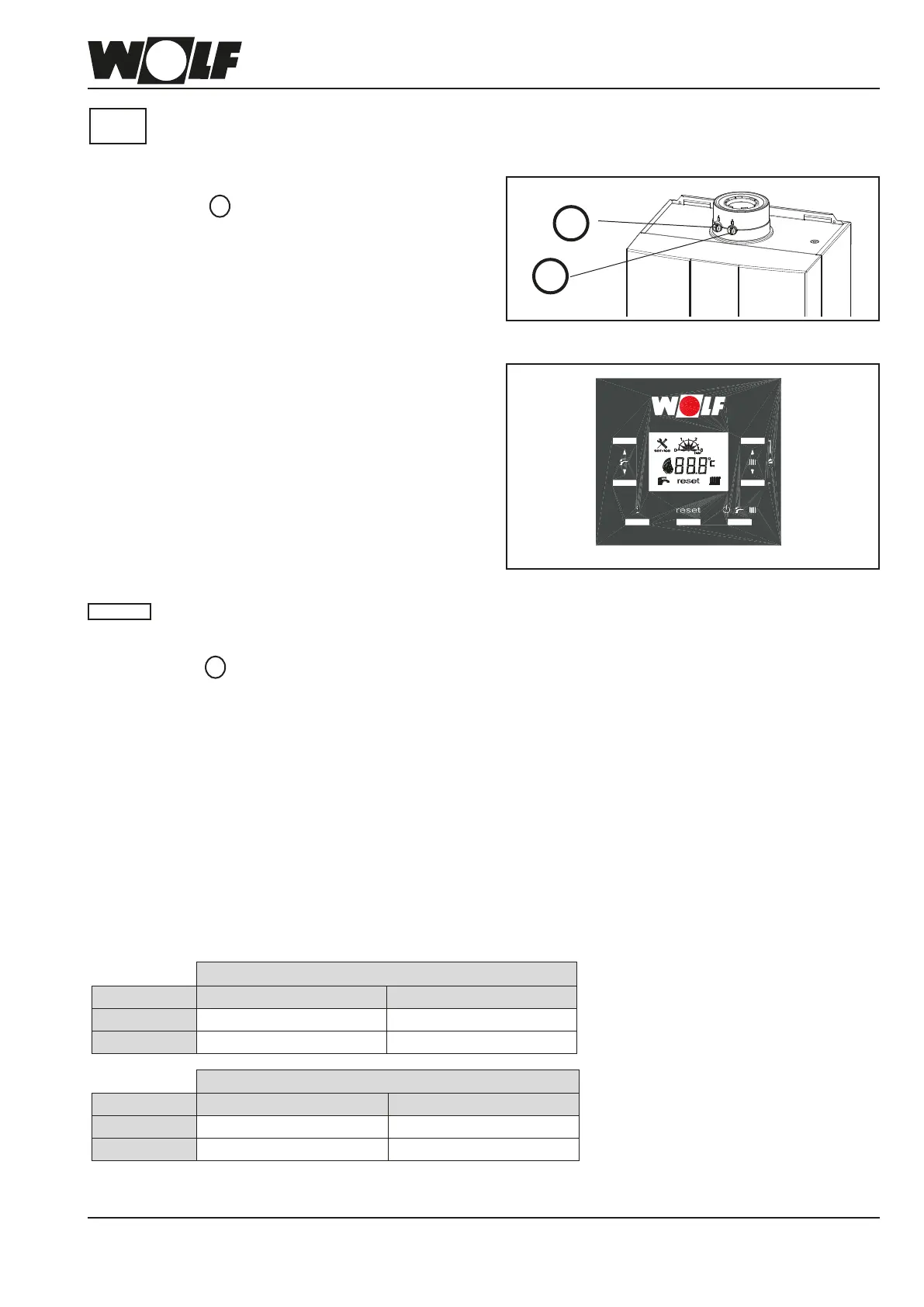

Fig: Checking the ue gas parameters

Checking the intake air

1. Remove screw A from the left hand test port.

2. Open the gas ball valve.

3. Insert the test probe.

4. Switch ON the boiler and enable the emissions test

mode via buttons 6 and 7 (press and hold for 5 s).

5. Check the temperature and CO

2

.

6. In the case of a balanced ue, the ue is not gas-tight if

the CO

2

content is > 0.3 %. The leak must be rectied.

7. After the test has been completed, switch the boiler OFF,

remove the test probe and close the test port. Ensure

the screws are tightly secured.

Checkingtheuegasparameters

When the test port is open, ue gas can escape

into the installation room. There is a risk of

asphyxiation.

1. Remove screw B from the right hand test port.

2. Open the gas ball valve.

3. Insert the test probe.

4. Switch ON the boiler and enable the emissions test

mode via buttons 6 and 7 (press and hold for 5 s).

5. Carry out the checks after a minimum of 20 s of

operation, measuring rst at upper load and then at

lower load.

6. Flue gas values (for permissible values, see table)

7. After the test has been completed, switch the boiler OFF,

remove the test probe and close the test port. Ensure

the screws / gasket are tight / seated rmly.

Please note

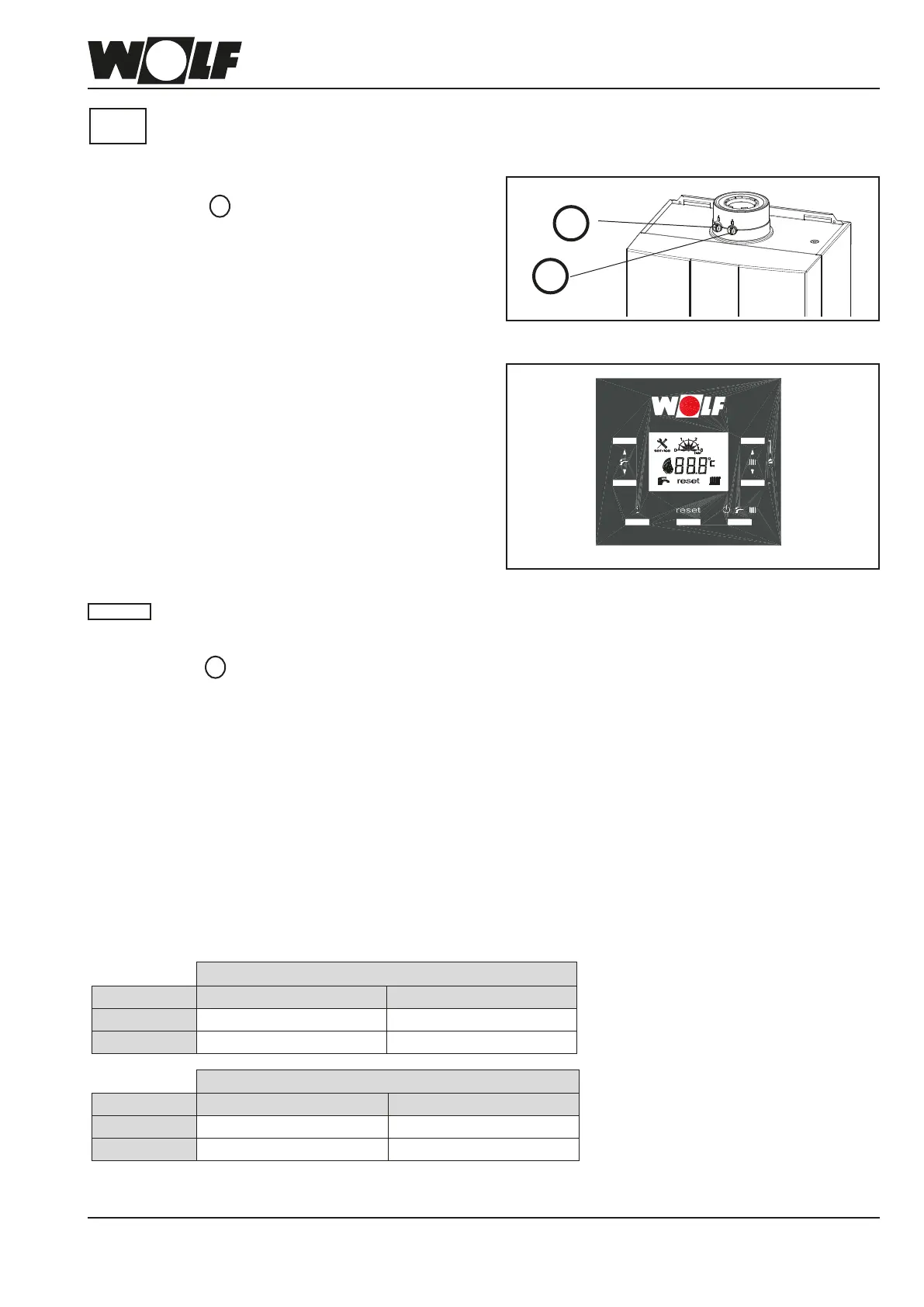

1

2

4

6

7

Fig: Control unit buttons

5

FGB / FGB-K appliance closed at upper load

Gas type

CO

2

in % O

2

in %

Natural gas E/H/L

9.3 % ± 0.2 % 4.2 ± 0.3 %

LPG P 10.5 % ± 0.2 % 4.9 ± 0.3 %

FGB / FGB-K appliance closed at lower load

Gas type

CO

2

in % O

2

in %

Natural gas E/H/L

9,1 % ± 0.2 % 4,7 ± 0.3 %

LPG P 10.0 % ± 0.2 % 5.7 ± 0.3 %

Table: Flue gas parameters

A

B

Flue gas test port

Intake air test port

25. Checking the combustion

parameters

A ue gas emissions test by a contractor is necessary after every modication of the components, including the

control unit PCB, fan, mixing device, burner and gas valve.

Test the combustion parameters with the appliance closed.

Please

note

Loading...

Loading...