3064458_201811

19

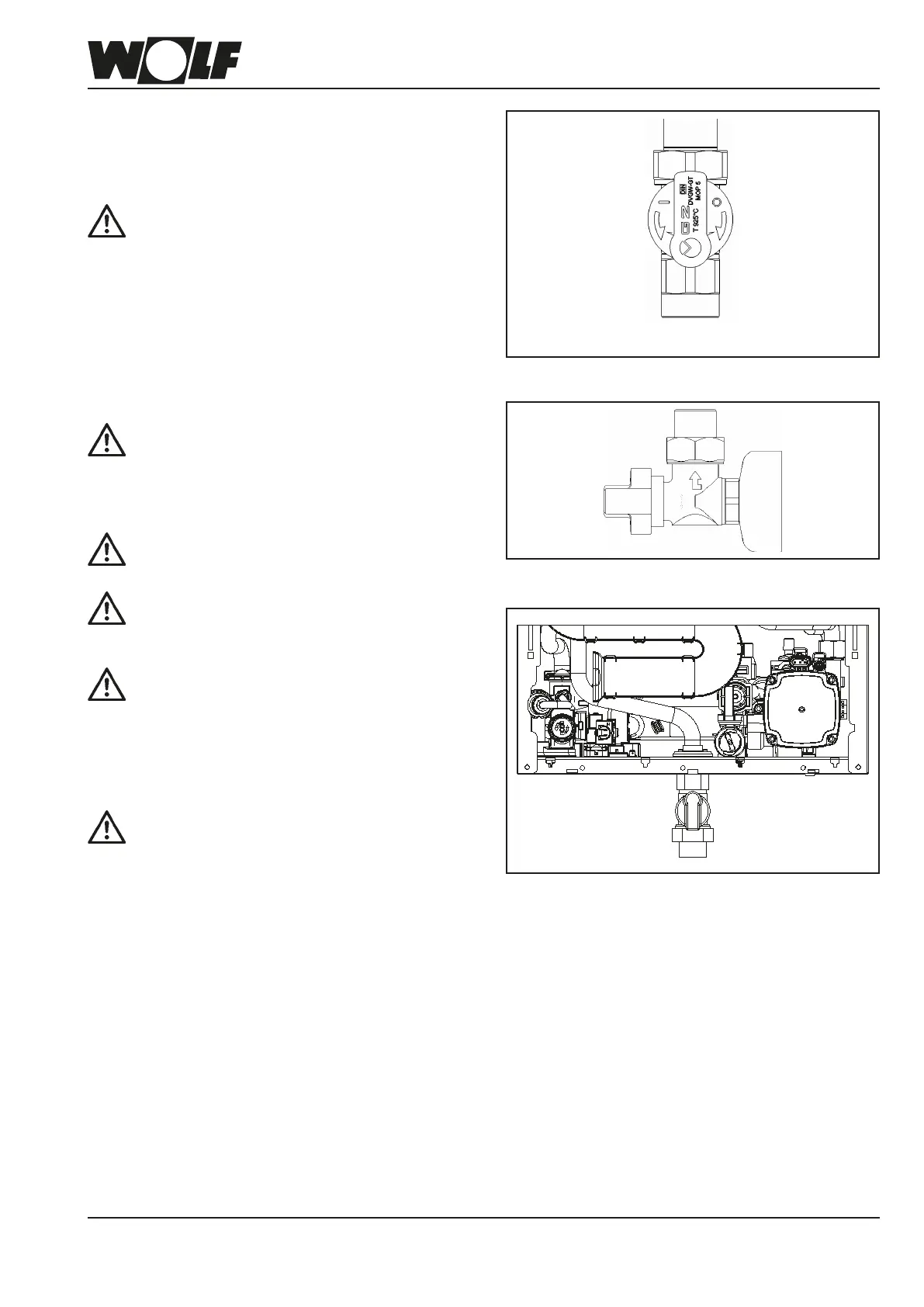

Fig: Gas ball valve, straight (accessories)

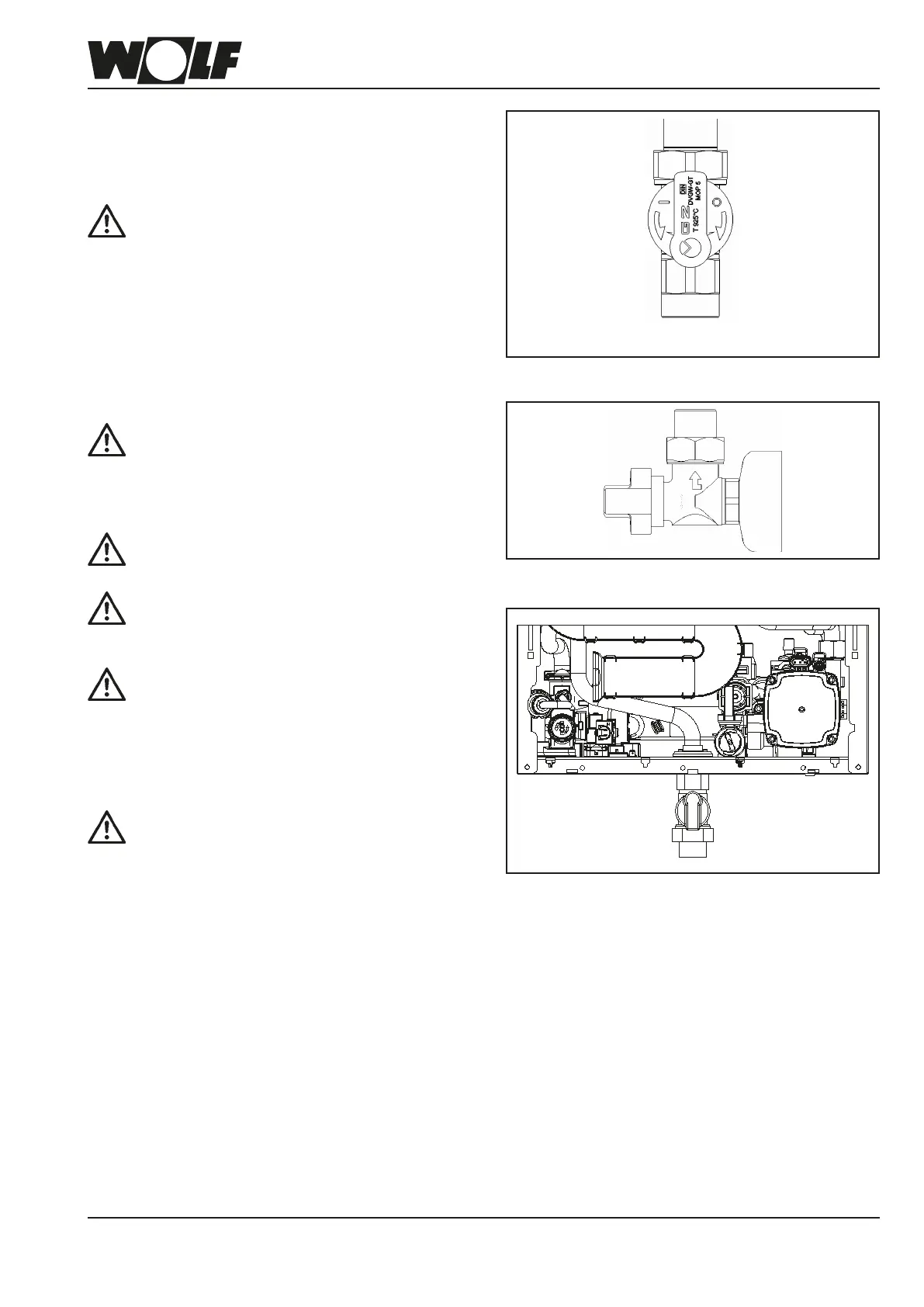

Fig: Gas ball valve, angled (accessories)

Fig: Gas connection installation

Seite 16

Gaskugelhahn, Durchgangsform

Connect the gas supply line at the gas connection or the

expansion joint (recommended) using gas connection

R½" and an approved sealant. Ensure the supply line is

stress-free.

Only a licensed gas tter may route the gas pipe

and make the gas connections.

Remove all residues from the heating pipework

and the gas line prior to connecting the

condensing boiler, particularly in older systems.

Prior to commissioning, test all pipe and gas

connections for leaks. Inappropriate installation

or using unsuitable components or assemblies

may lead to gas escaping, which results in a risk

of poisoning and explosion.

Install a gas ball valve with re protection in the

gas supply line upstream of the condensing

boiler. This prevents a risk of explosion during a

re. Size the gas supply line in accordance with

DVGW-TRGI regulations.

Mount the gas ball valve in an easily

accessible place.

Carry out a tightness test on the gas line

without the gas condensing boiler. Never

release the test pressure via the gas valve.

Gas ttings on the appliance should be

pressure tested to a maximum of 150 mbar.

Higher pressure may damage the gas valve,

resulting in a risk of explosion, asphyxiation

or poisoning. When pressure testing the

gas line, close the gas ball valve on the gas

condensing boiler.

When installing the gas connection, ensure

all ttings are sufciently tightened to

prevent gas leaks.

11. Gas connection

Loading...

Loading...