3064458_201811

39

17. Parameter description

Important information:

In these schematic diagrams, shut-off valves, air vent valves and safety equipment are not fully represented.

These should be provided subject to the individual system, in line with the applicable standards and regulations.

Hydraulic and electrical data can be found in the Hydraulic System Solutions technical guide.

In DHW mode, the pump runs at this set value. Independent of the pump control type

set in H37.

Parameter H41

Feed/heating circuit pump speed,

DHW

Factory setting: see table

Setting range: 15 to 100 %

Individual setting:_____

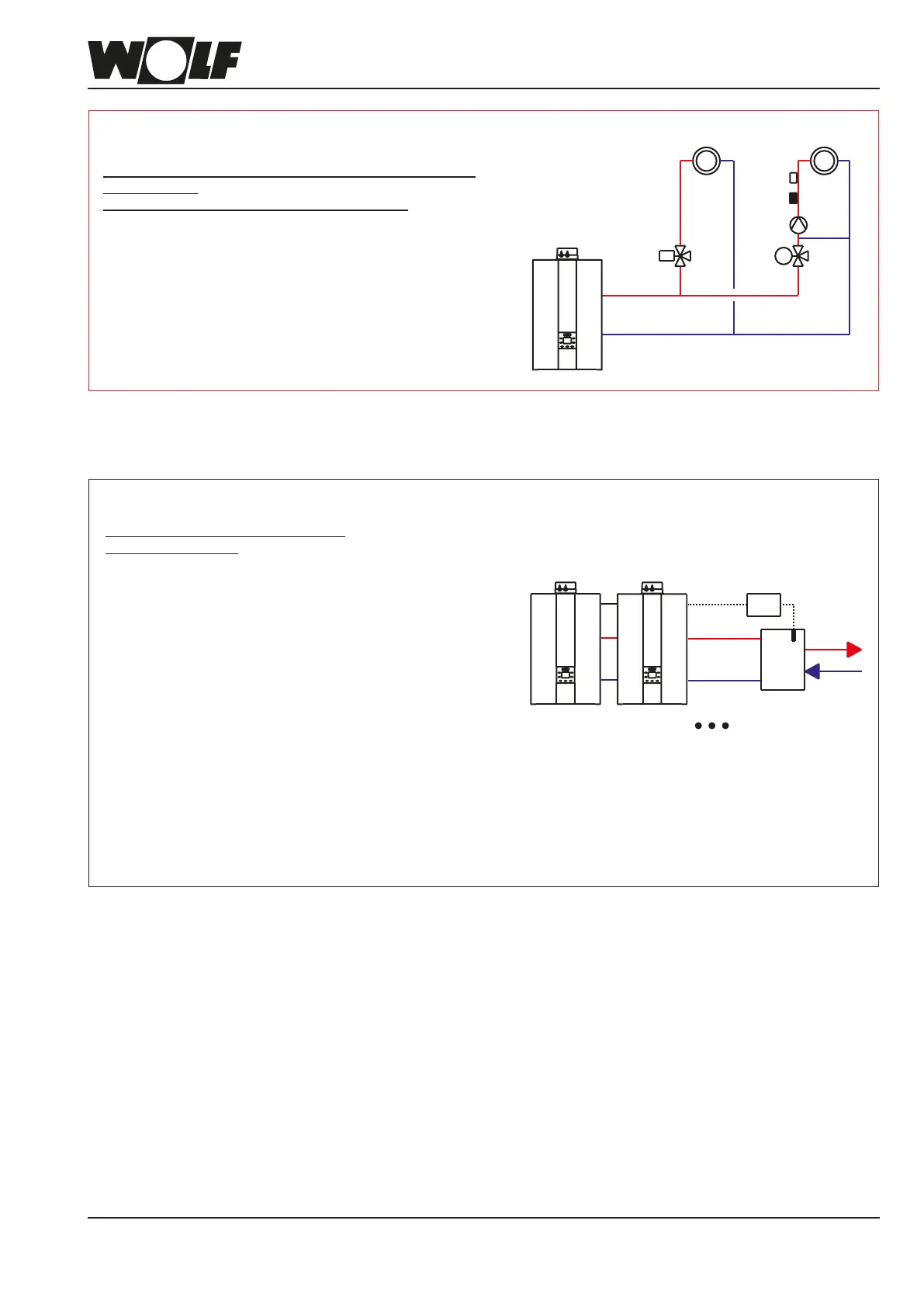

Systemconguration60

Cascade (automatic setting if cascade

module is connected)

• eBus address H10 must be set for each

condensing boiler

• Burner starts following a demand from the cascade

module via eBus

(0-100 % burner output; min. to max. within the

programmed limits H02 and H04)

• Internal appliance pump is enabled as a feed pump

• Header temperature control via cascade module

• Automatic output reduction when approaching TV

max

(H08)

is enabled. Shutdown when TV

max

is reached

• A low loss header or plate heat exchanger can be used to

provide hydraulic separation.

eBus

SAF

KM

H10 = 1 H10 = 2

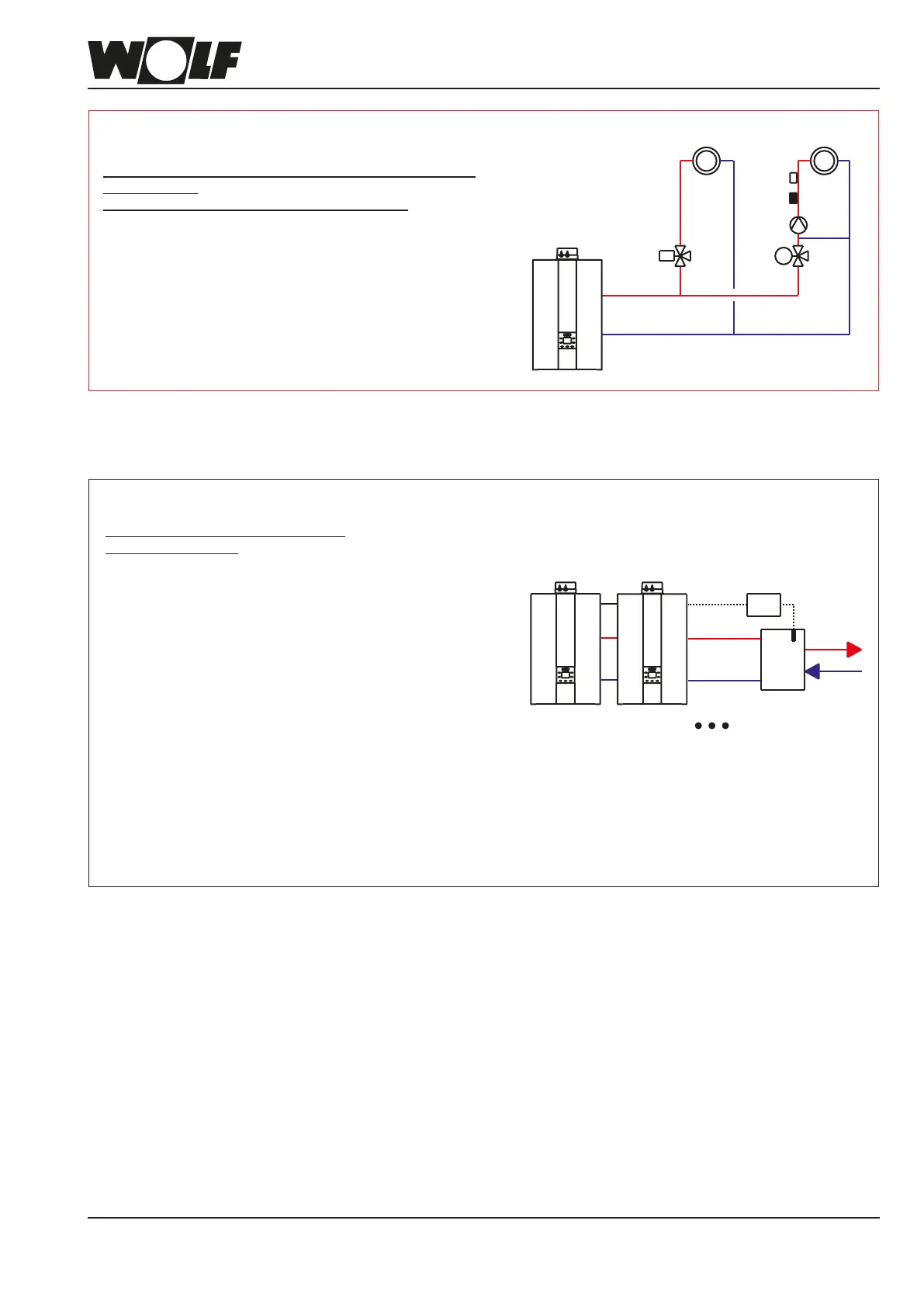

Systemconguration02

Direct heating circuit and one or more circuits with mixer via

mixer modules

(no direct heating circuit at the condensing boiler)

• Burner starts subject to demand from the connected

circuits with mixer

• Internal appliance pump is enabled as a feed pump

• Thermostatic boiler control;

set value is specied by circuits with mixer

HK MK1

M

Loading...

Loading...