Manual 26833 TecJet 52 Gen II

Woodward 15

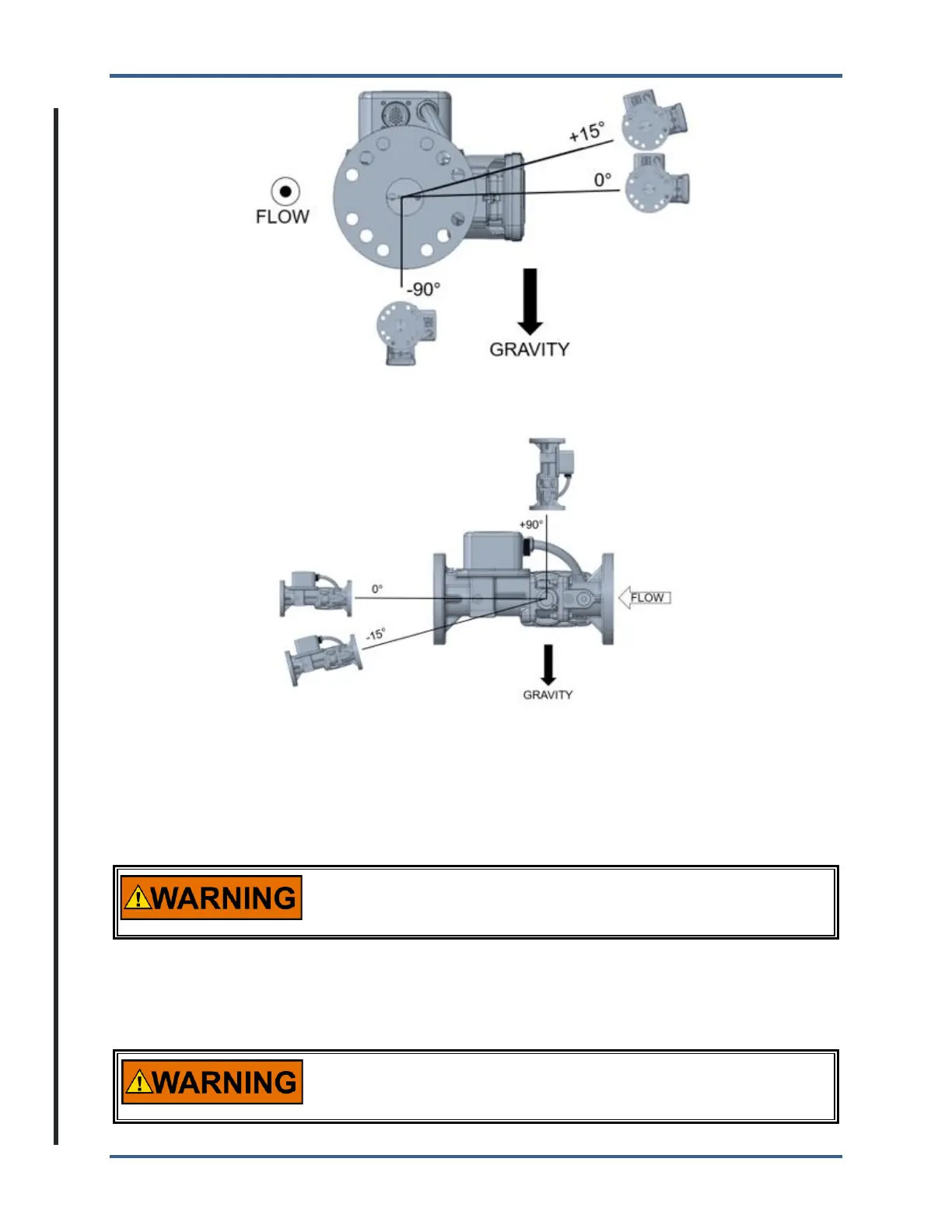

Figure 2-1b. Allowable Actuator Orientations

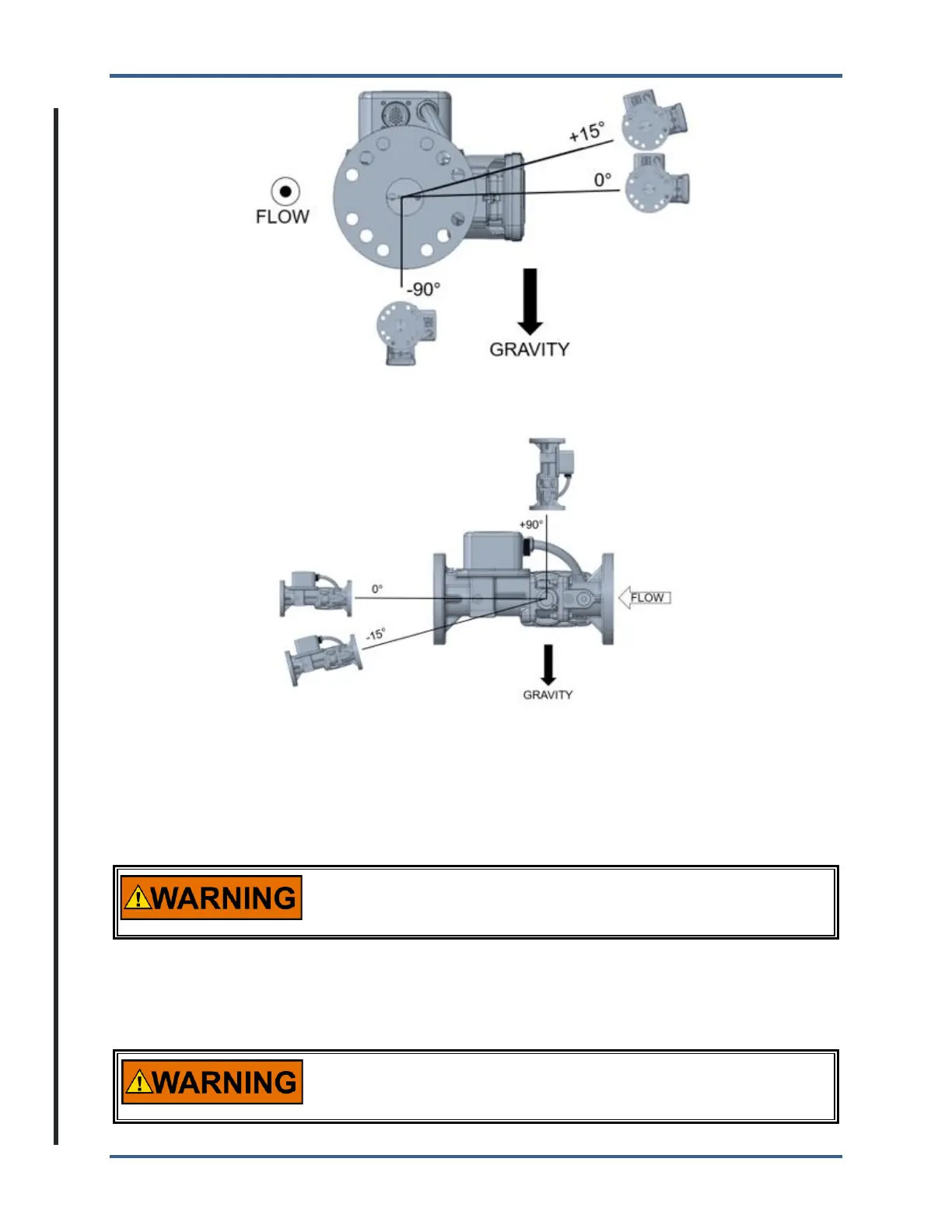

Figure 2-1c. Allowable Bore Orientations

For on-engine applications, a suitable bracket must be constructed to support the weight of the valve on

the engine. See the outline drawing (Figure 2-2) for the valve mounting feet hole and hole-location details.

An optional mounting bracket is available to provide a base mounting to the TecJet (Figure 2-3). All

mounting configurations should ensure that moment loads are not applied either through installation or

thermal stress that could cause the valve to bind and lose functionality.

The TecJet 52 is not intended to support the inlet or outlet piping.

Suitable brackets must be constructed to support the valve and

piping separately to prevent damage to the TecJet.

The inlet and outlet piping of the TecJet 52 must be in accordance with ANSI/ISA-S75.02 to ensure the

flow metering accuracy specified elsewhere in this manual. However, an inlet piping length as short as 6

diameters and an outlet piping length as short as 2 diameters can typically be used with a negligible loss

in valve metering accuracy.

EXPLOSION HAZARD—Leak check all gaseous fuel connections.

Leaking gaseous fuel can cause explosion hazards, property

damage, or loss of life.

Loading...

Loading...