SERVICE AND SPARES

Greenstar Si Compact

ErP

- 6 720 813 278 (2015/07) 43

▶ Re-check the fan pressure readings.

If the boiler, after completing the above checks, fails the fan pressure

test then contact Worcester, Bosch Group for advice.

▶ After the measurements are taken switch the boiler off.

▶ Remove the combustion air intake pipe.

▶ Disconnect the manometer and replace the test point cover.

▶ Replace the combustion air intake pipe.

7.6 FLUE GAS ANALYSIS

Combustion test

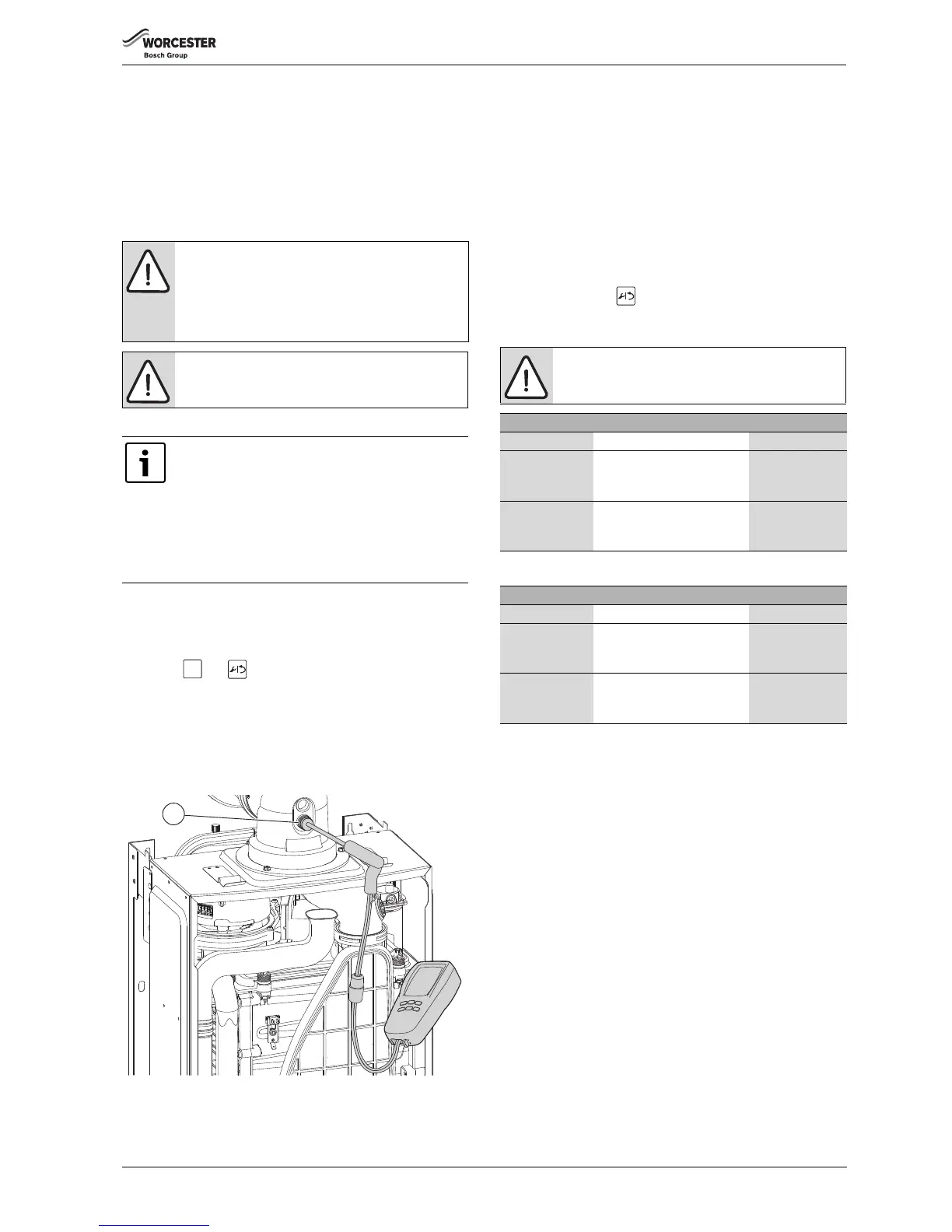

▶ Connect the flue gas analyser to the flue gas sampling point (1) as

shown in the figure below.

▶ Ensure that the probe reaches the centre of the flue gas exhaust,

adjust the cone on the probe so that it seals the sample point and

correctly positions the end of the probe.

▶ Press the and buttons together

– The chimney sweep symbol will be displayed at the top of the

screen.

– “Max” will flash at the bottom of the screen.

– The boiler will ramp up to maximum output in approximately 30 to

35 seconds.

▶ Run the boiler at maximum output for at least 10 minutes.

▶Check the CO/CO

2

readings against the information in table 26.

Fig. 69 Combustion test

▶ Set the boiler to minimum power by pressing the down arrow button.

– “Min” will flash at the bottom left of the screen.

– The boiler will take 30 to 35 seconds to ramp down to minimum

output.

– Allow the boiler to stabilise at minimum output.

▶Check the CO/CO

2

readings against those in tables 26 and 27

▶ Return the boiler to maximum, by pressing the UP arrow button, and

re-check the CO/CO

2

.

– “Max” will flash at the bottom left of the screen.

– The boiler will take approximately 30 to 35 seconds to ramp up to

maximum output.

– Allow the boiler to stabilise at maximum output.

▶ If correct, press the button and the boiler will return to normal

operation.

▶ Re-assemble and refit boiler case.

Example of a Natural Gas appliance reading:

•Maximum CO

2

reading taken = 9.5%

• The minimum CO

2

reading must be between 8.0% and 9.3%

(a minimum 0.2 lower than the maximum reading of 9.5%)

If the CO

2

is out of tolerance then please check:

▶ the gas inlet pressure,

▶the gas rate,

▶ the fan test pressure,

▶ the condition of burner,

▶ the flue and air intake, plus any possible blockages in the condensate

disposal.

▶ for leaks or obstructions in the gas way,

▶ that the injector is clean.

After all checks have been and the CO

2

is still out of tolerance then the

gas valve must be replaced.

NOTICE: Combustion testing

▶ Combustion testing must be carried out by a

competent person. Testing must not be attempted

unless the person carrying out the combustion check

is equipped with a calibrated Combustion Analyser

conforming to BS 7927 and is competent in its use.

NOTICE: Gas inlet pressure

▶ Ensure that the gas inlet pressure has been checked

and is satisfactory, refer to section 6.5.1

When running in maximum output, and the water

temperature is 65°C or less, the boiler will operate both

the central heating and DHW circuits with the diverter

valve in the mid position. It will be necessary to run

sufficient water through the DHW circuit to ensure that

the boiler will not cycle on low heating demands.

This is to allow sufficient time for the setting procedure.

When the water temperature reaches 75°C the diverter

valve will switch to CH only.

Loading...

Loading...