FAULT FINDING AND DIAGNOSIS

Greenstar Si Compact

ErP

- 6 720 813 278 (2015/07)66

8.5.3 MENU 1 - SYSTEM PARAMETERS

Not applicable for Greenstar Si Compact

ErP

.

Initially Menu 1 will be displayed, but will contain no options.

8.5.4 MENU 2 - BOILER PARAMETERS

1. Select Menu 2 via the and scroll buttons.

2. Press and hold the button for one second to enter Menu 2.

This menu lists the boiler parameters, which can be adjusted in this

menu.

To modify setting, select the desired menu option (refer to table 29) and

press the button, the option will flash.

Adjust the parameter using the and arrow buttons and press

the button to confirm.

A will display for three seconds to confirm the

update of the new value.

If the setting is confirmed please record the saved value in the empty box

next to the relevant setting in Table 29.

The same process is used for adjusting all Menus 1, 2, 3 and Test.

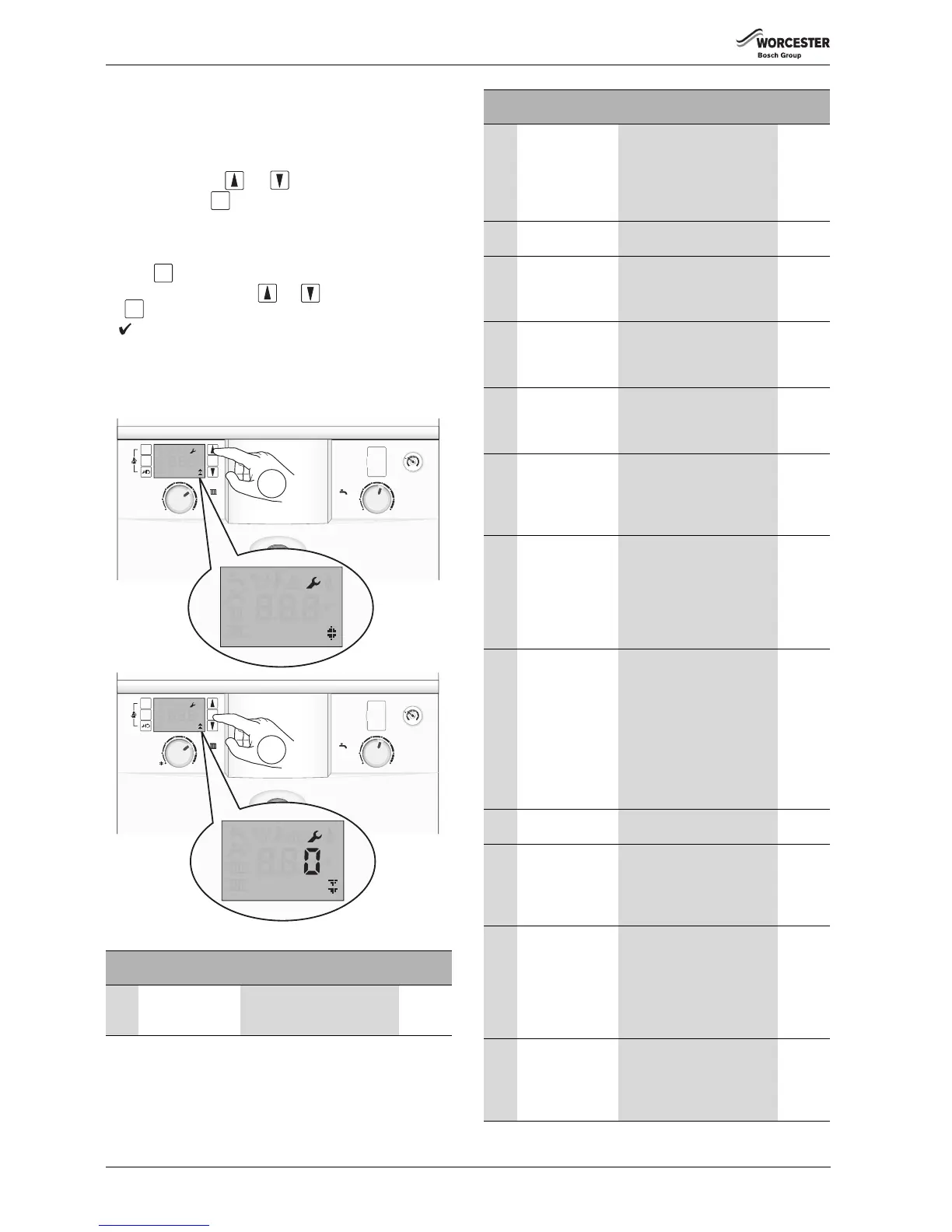

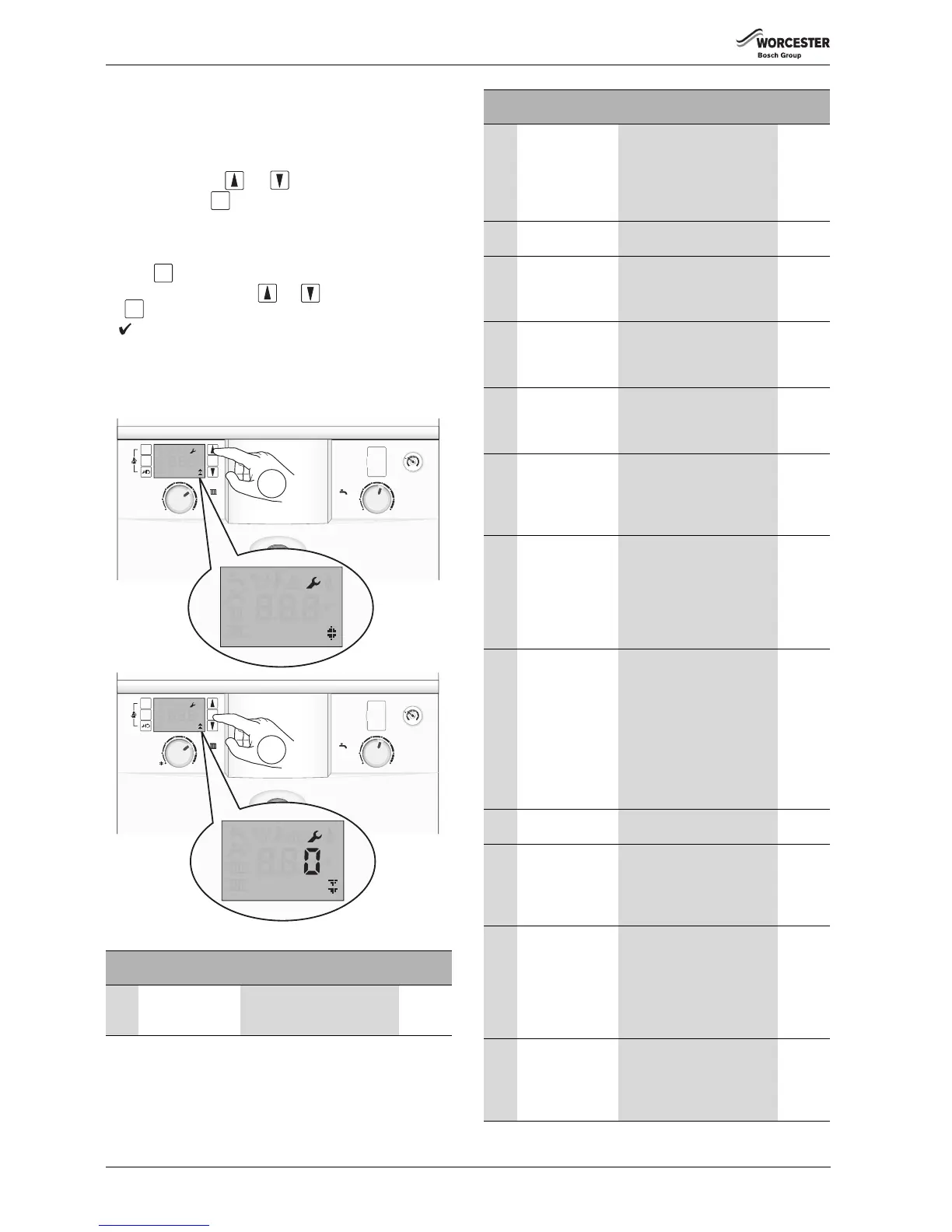

Fig. 126 Menu 2 selection

Para

No.

Parameter Description Updated

value

2.1A Maximum power

CH

Range rate the CH of the boiler.

Adjustment in kW.

The maximum is 24kW.

Table 29 Menu 2 parameters

ok

2.1C Pump head

selection

Select the right pump map

(load and modulation

percentage) to suit the

property.

0 = Variable speed setting

1 to 4 option pump maps

2.1E Pump energy

saving mode

4 = mode ON,

5 = mode OFF

2.1H Minimum pump

speed (pump

speed at maximum

CH burner load)

This parameter is only visible

when 2.1C is set to 0. Then the

min.pump speed can be set.

2.1J Maximum pump

speed (pump

speed at maximum

burner load)

This parameter is only visible

when 2.1C is set to 0. Then the

max.pump speed can be set.

2.2C Air purge mode This feature can be selected to

purge the system and boiler of

air.

0 = off, 1 = auto, 2 = on

2.3B Anti fast cycle time

for CH

This sets the amount of time

between stop and starts of the

main heat exchanger. The

default is 5 minutes, the range

is 3 to 45 minutes.

2.3C Anti fast cycle flow

temperature

hysteresis

(negative tolerance

only)

This sets the temperature drop

before the burner re-starts, 6°K

is the default. This is used in

conjunction with the “Anti fast

cycle time”

The range is from 2 to 15°K in

1°K steps.

2.3F CH delay after DHW

demand

The default time is 1 minute

and can be adjusted to be

between 0 and 30 minutes.

This feature helps to keep the

DHW heat exchanger hot if

frequent demands are made.

The boiler will not burn extra

gas.

CH will not be heated during

this set time period.

2.5F Service reminder

time

Between 1 and 72 months can

be set

2.7A Operation/fault

indicator (blue

light) activation

0 = The blue light will only

operate as a flashing fault alert.

1 = The blue light will operate

as a boiler operation and fault

alert. This is set to 1 by default.

2.9E Turbine signal

delay

Delay time set to ignore a

temporary DHW demand.

Maximum delay is three

seconds which can be set in

¼ second increments,

e.g. 0.5 seconds is displayed as

2 or 1 second as 4.

2.9F Pump post purge

time for CH

The default pump overrun time

is 3 minutes. This can set

between 3 and 30 minutes. The

actual time will be affected by

the Pump Energy Saving mode.

Para

No.

Parameter Description Updated

value

Table 29 Menu 2 parameters

Loading...

Loading...