OPEN FLUE MODEL (CF/LLD)

This includes conventional flue and standard low level and high

level horizontal discharge kits.

6.1 In order to ensure clean and efficient combustion, an

adequate supply of air must be delivered to the combustion

chamber. To provide sufficient air, a suitable inlet should be

provided into the room or space in which the appliance is

situated, the size of which is detailed in Table 7. An air brick or

other form of continuous air supply may have to be built into

the installation in order to ensure an adequate supply of air.

6.2 If the appliance is to be installed in a confined space or

compartment, two air vents are required, one at high level and

one at low level. The minimum free area of each vent is given in

Table 8 and depends whether the air is taken from another room

or from outside the building. Where the air is taken from another

room that room must contain an air inlet as described in 6.1.

6.3 There must be sufficient clearance around the appliance to

allow proper circulation of ventilation air. The clearances

required for installation and servicing will normally be adequate

for ventilation. See Section 4.4.

ROOM SEALED BALANCED FLUE MODEL (RS)

6.4

The appliance does not require a separate vent for

combustion air.

6.5 Installation in cupboards or compartments require

permanent vents for cooling purposes, one at high level and one

at low level, either direct to outside air or to a room. Both vents

must pass to the same room or be on the same wall to the

outside wall to the outside air. The minimum air vent free area is

given in Table 9.

6.6 There must be sufficient clearance around the appliance to

allow proper circulation of ventilation air. The clearances

required for installation and servicing will normally be adequate

for ventilation. See Section 4.4.

A flue system must be provided in accordance with BS5410:

Part 1 and with the current Building Regulations.

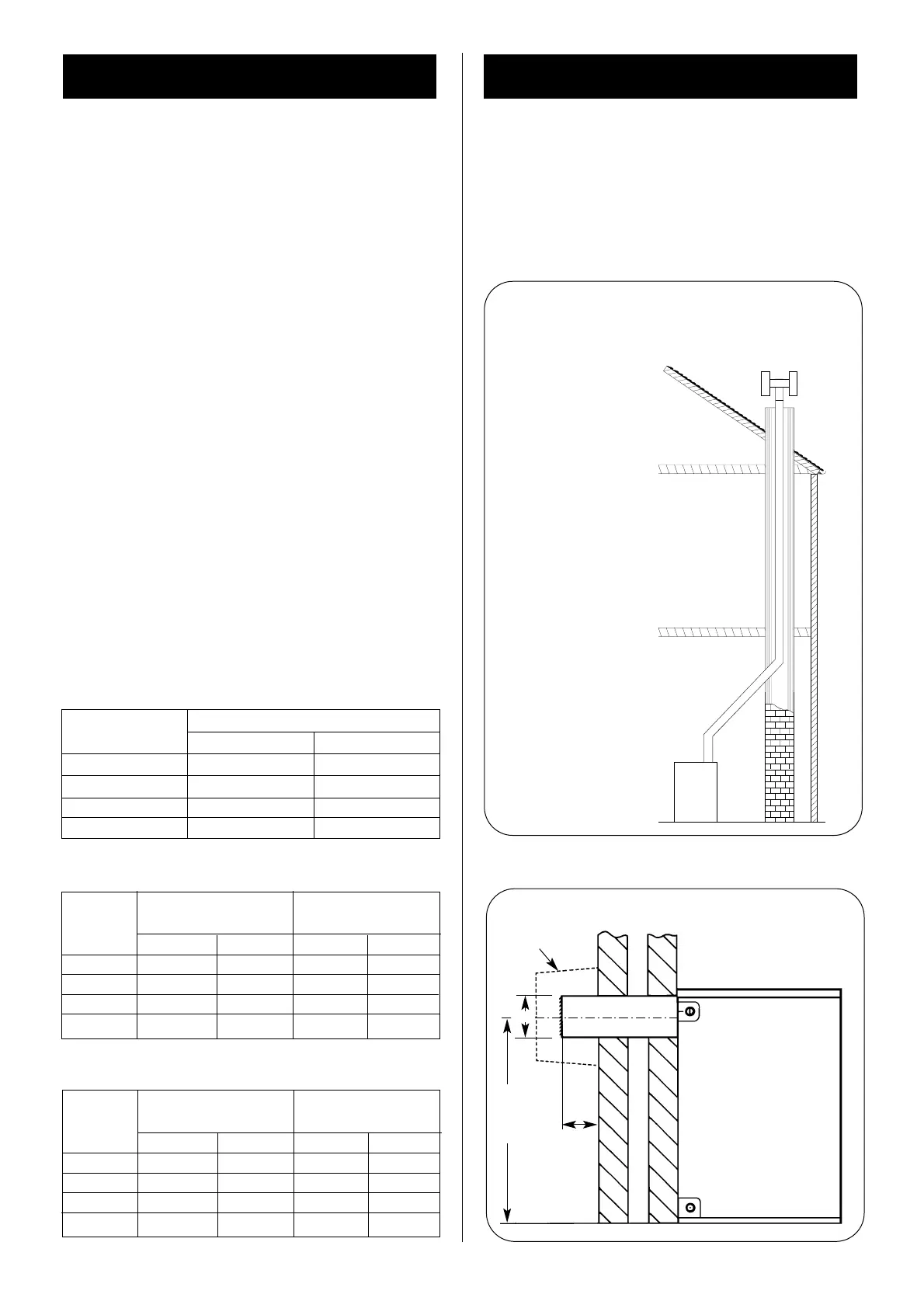

7.1 Conventional Flue (CF). See Fig 5.

Conventional Flue Diameters: 12/14 – 100mm (4in.)

15/19 – 100mm (4in.)

20/25 – 100mm (4in.)

26/32 – 125mm (5in.)

NOTE: External flues systems must be of the insulated flue type.

The boiler is fitted with a conventional flue locating spigot.

7. Flue System6. Air Supply

11

Fig. 7. Flue Installation.

Where possible take the

flue above the apex – if not

above the apex an anti

down-draught terminal is

advisable.

Brick Chimney.

Use of a flue liner

is recommended.

Use as few bends as

possible.

Use 135° Bends.

Flues must not be reduced from

the boiler take off diameter.

ALWAYS TAKE THE FLUE ABOVE THE EAVES

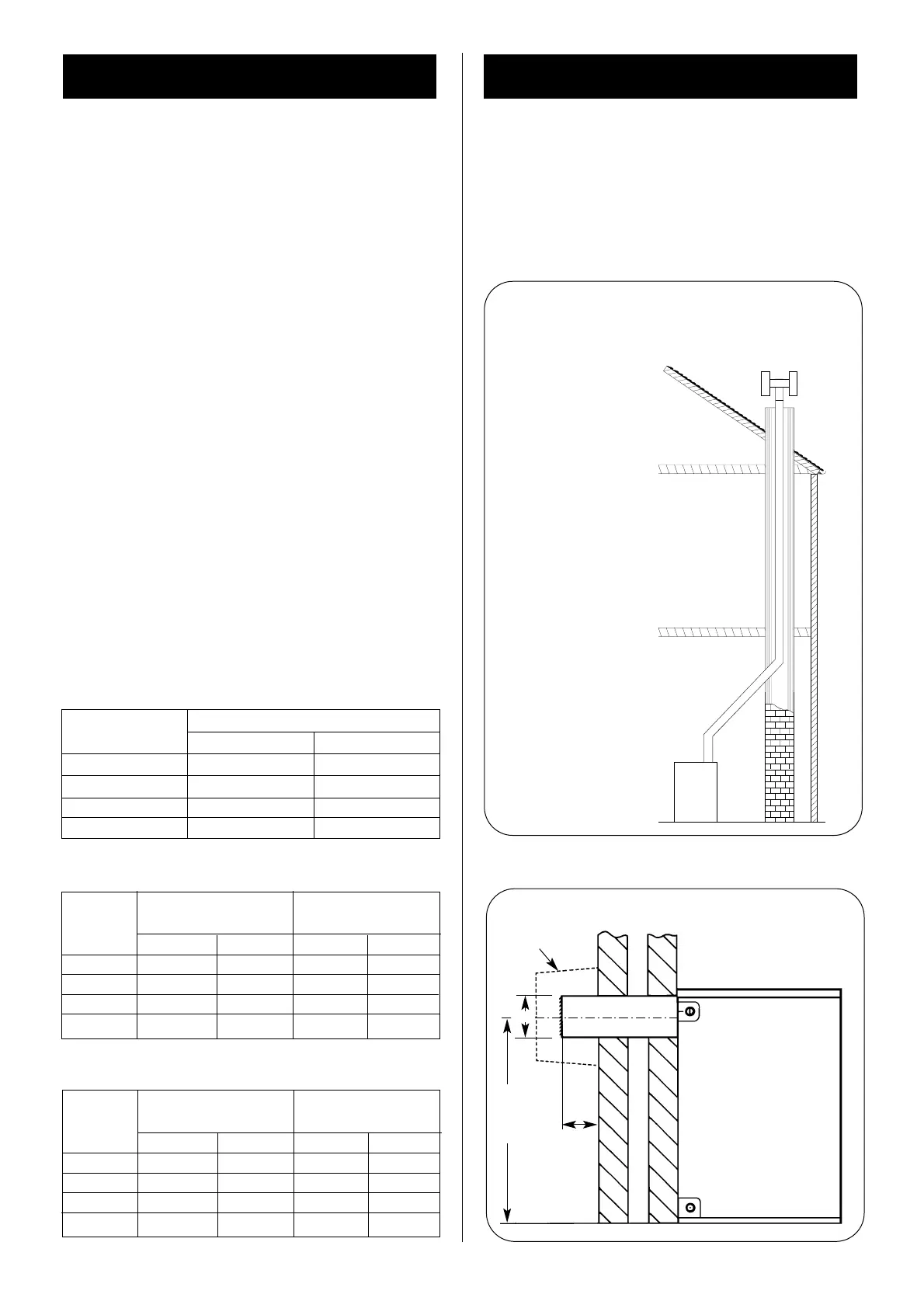

Fig. 8. Flue Installation (Rear Discharge).

See Fig. 10 for flue

terminating positions.

80

min.

FLUE GUARD

766 mm

140

Table 8. Minimum Air Vent Free Area for Open Flue

appliances installed in a compartment.

Appliance

Ventilation to room or

Ventilation to outside

model

internal space

High Level Low Level High Level Low Level

12/14 154cm

2

231cm

2

77cm

2

154cm

2

15/19 209cm

2

314cm

2

105cm

2

209cm

2

20/25 275cm

2

413cm

2

138cm

2

275cm

2

26/32 352cm

2

528cm

2

176cm

2

352cm

2

Table 9. Minimum Air Vent Free Area for Room Sealed

appliances installed in a compartment.

Appliance

Ventilation to room or

Ventilation to outside

model

internal space

High Level Low Level High Level Low Level

12/14 154cm

2

154cm

2

77cm

2

77cm

2

15/19 209cm

2

209cm

2

105cm

2

105cm

2

20/25 275cm

2

275cm

2

138cm

2

138cm

2

26/32 352cm

2

352cm

2

176cm

2

176cm

2

APPLIANCE

AREA OF AIR INLET

cm

2

in.

2

12/14 77 12

15/19 105 16.5

20/25 138 21.5

26/32 176 27.5

Table 7. Minimum Combustion Air Inlet Free Area for

Open Flue appliances

Loading...

Loading...