17

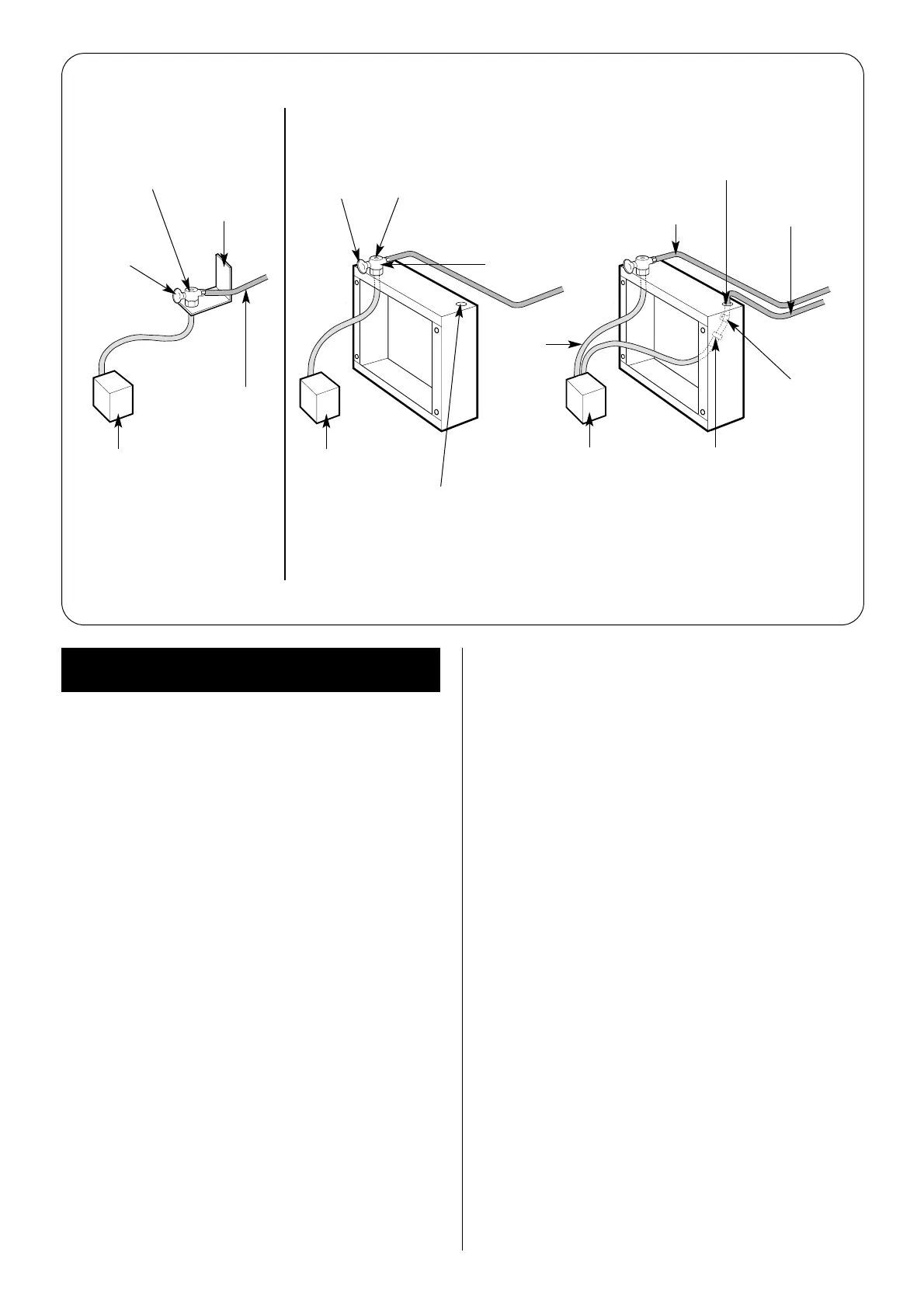

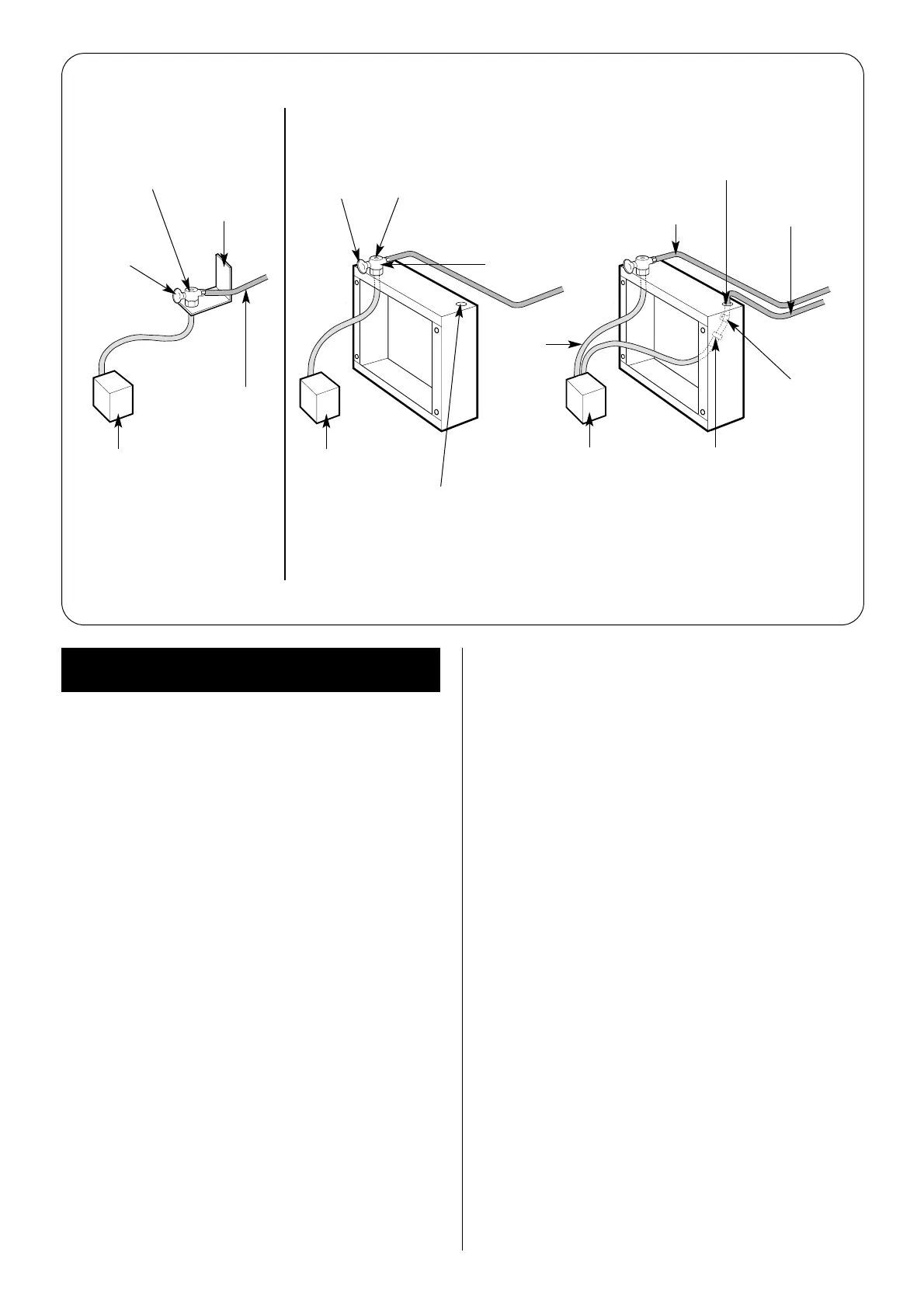

Fig. 14. Oil Pipe Installation.

(b) Single Pipe System.

RS Appliance

(a) CF Bracket.

CF Appliance

(c) Double Pipe System or

Single Pipe Suction Lift with De-aerator.

Burner

oil pump

Open

grommet

Turn fully

clockwise

to isolate

Blind

grommet

Air

bleed

Burner

oil pump

Burner

oil pump

10mm or 12mm

copper pipe

1

⁄4" BSP female x

10/12mm

compression coupling

(not supplied)

10mm

copper pipe

10mm

copper pipe

Retaining

clip

Isolating

valve

Isolating

valve

Pipe support

bracket

Turn fully

clockwise

to isolate

Flexible

oil hose

The heating and hot water system must be provided in accor-

dance with the current Building Regulations.

9.1 The appliance incorporates a circulating pump. No other

pump is required. The appliance will operate satisfactorily on a

two-pipe small bore or micro bore system using

thermostatically controlled radiator valves.

9.2 The appliance incorporates a three-port, two-way diverter

valve which diverts the boiler output to the Heatslave tank in

response to a demand from the Domestic Hot Water Control

Thermostat or the flow switch. The valve is powered open in

response to a demand from the Central Heating Control

Thermostat or a room thermostat, and the boiler output is

diverted to the heating circuit.

If there is a demand from both the Heatslave tank and the

central heating, the valve will give priority to the Heatslave tank.

The central heating will therefore remain switched off for a short

period of time. This delay will vary depending on the appliance

output and the quantity of energy required to satisfy the

domestic hot water demand.

The Heatslave tank priority can be temporarily overridden to

regain the central heating output by turning the Domestic Hot

Water Thermostat fully anti-clockwise for the duration of the

warm up period. This will prevent the Heatslave tank taking

priority for the tank warm up period of approximately 20

minutes and may be found advantageous to give quicker

heating to the dwelling when starting from cold.

9.3 On new installations it is recommended a room thermostat

or programmable room thermostat is used in the main zone and

thermostatic radiator valves are used in further heating zones.

On existing systems where a room thermostat is already fitted it

is recommended to fit thermostatic radiator valves at least in

the sleeping areas.

9.4 A check valve is incorporated in the hot water primary

circuit to prevent gravity circulation from the tank to the boiler.

9.5 When employing a central heating system where primary

water flow may be prevented during a pump overrun situation

(e.g. by using thermostatic radiator valves on all radiators), a

bypass valve should be fitted between the flow and return pipes.

9.6 The pressure jet burner fitted to the appliance has full automatic

control and there is no requirement for heat leak radiators.

9.7 It is strongly recommended that isolating valves are fitted to

the central heating flow and return pipes. This will allow the

boiler and Heatslave tank to be drained for service work without

having to drain down the whole central heating circuit.

9.8 A drain point should be provided in the domestic hot water

pipework at any point below the height of the domestic hot

water heat exchanger.

9.9 Provision should be made to allow air to be vented from the

domestic hot water pipework at any high points. Failure to vent

the air will cause the flow switch to operate momentarily if a

cold water tap is turned off rapidly.

9.10 Any unused boiler tappings should be plugged prior to

filling.

9.11 The primary central heating system should be flushed and

treated in accordance with recommendations of BS 7593: 1992

before the system is handed over to the user.

9.12 System Pipework

Sealed System Pipework

(See Figs. 15 and 16).

Copper pipework must be used when installing the appliance on

a sealed system.

Open Vent Primary System Pipework (See Figs. 17.)

The first meter of pipework from all appliance connections must

be in copper; afterwards copper or plastic pipe can be used. The

plastic pipe must be manufactued to BS 7291 and installed to BS

5955 part 8. It is recommended to protect the system

components the plastic pipe specified is resistant to the ingress of

oxygen.

9. System Considerations

Loading...

Loading...