6-3

ALIGNMENT & ADJUSTMENTS

Service

Manual

WorkCentre PE16 July 2003

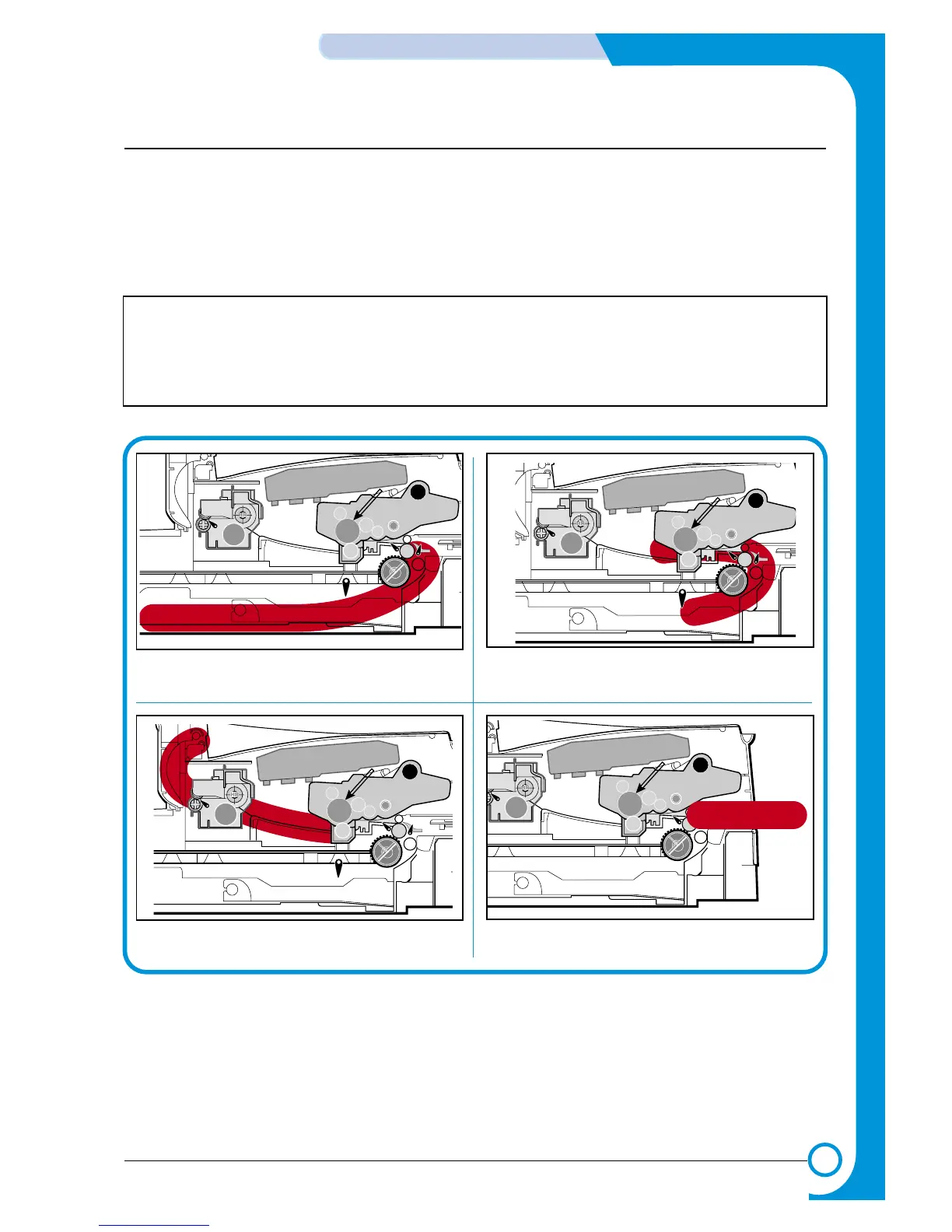

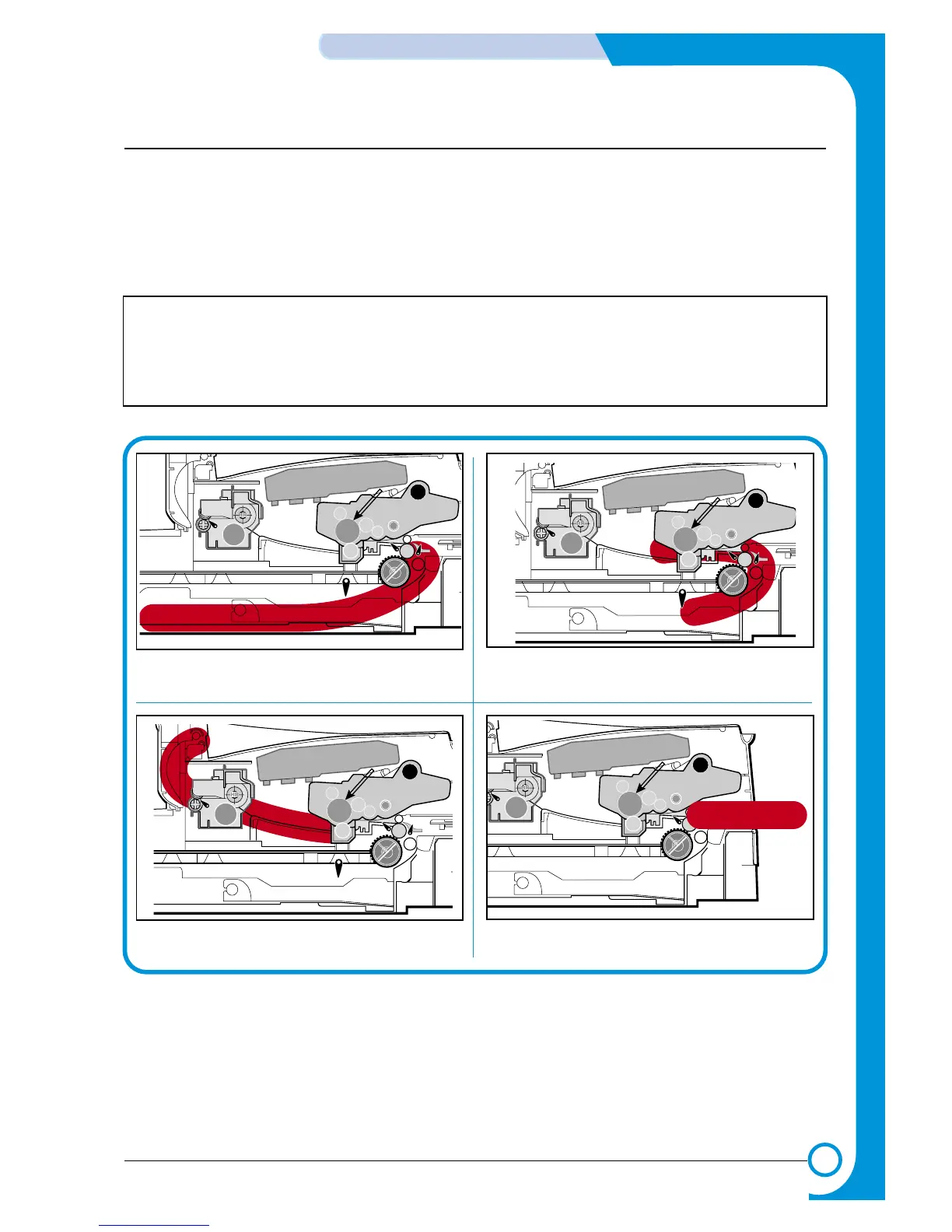

6.2 Clearing Paper Jams

Occasionally, paper can be jammed during a print job. Some of the causes include:

• The tray is loaded improperly or overfilled.

• The tray has been pulled out during a print job.

• The front cover has been opened during a print job.

• Paper was used that does not meet paper specifications.

• Paper that is outside of the supported size range was used.

If a paper jam occurs, the On Line/Error LED on the control panel lights red. Find and remove the

jammed paper. If you don’t see the paper, open the covers.

Do not use a tweezers or a sharp metal tool when removing a jam.

The covering of a metal part can be removed which can cause an electric leakage.

Loading...

Loading...