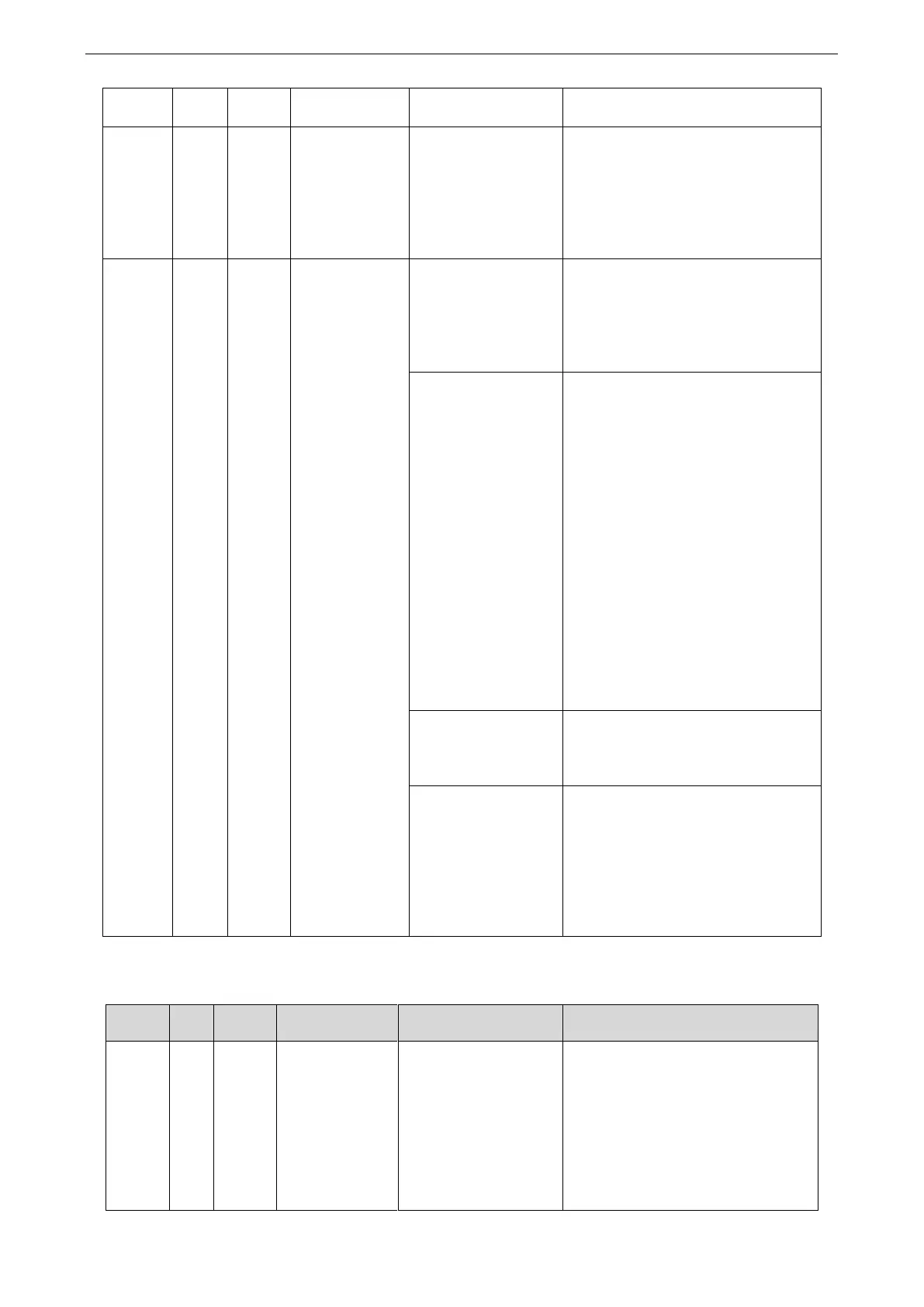

decreasing in one direction (0-9999

cycle display).

Power cable

disconnection

Any phase in UVW

of driver, cable or

motor broken

Disconnect the power supply of the

driver and check the connection of

the power cable. It is suggested that

the multimeter be used to test the

condition. After eliminating the

errors, the driver should be

re-energized.

Driver thermal

power overload

Check if the driver U3-00 is

identical with the motor code of the

motor label (the number after

MOTOR CODE), if not, please

change to the same one, then power

on again.

Overload, the actual

operating torque

exceeds the rated

torque, and

continuous

operation for a long

time. (Monitor

U0-02 to check the

actual operating

torque. If the motor

is in normal

operation, it will not

jam or jitter. If the

U0-02 is longer than

100, it will be

considered improper

selection of the

motor.)

Increase the capacity of drivers and

motors. Extend the acceleration and

deceleration time and reduce the

load. Monitor the U-00, whether it is

running over speed.

Mechanisms are

impacted, suddenly

weighted and

distorted.

Eliminate mechanical distortion.

Reduce load

Motor action when

motor brake is not

opened

Measure the voltage of the brake

terminal and decide to open the

brake.

It is suggested to use servo BK

signal to control the brake lock. If it

is not servo control, attention must

be paid to the timing of brake

opening and motor action.

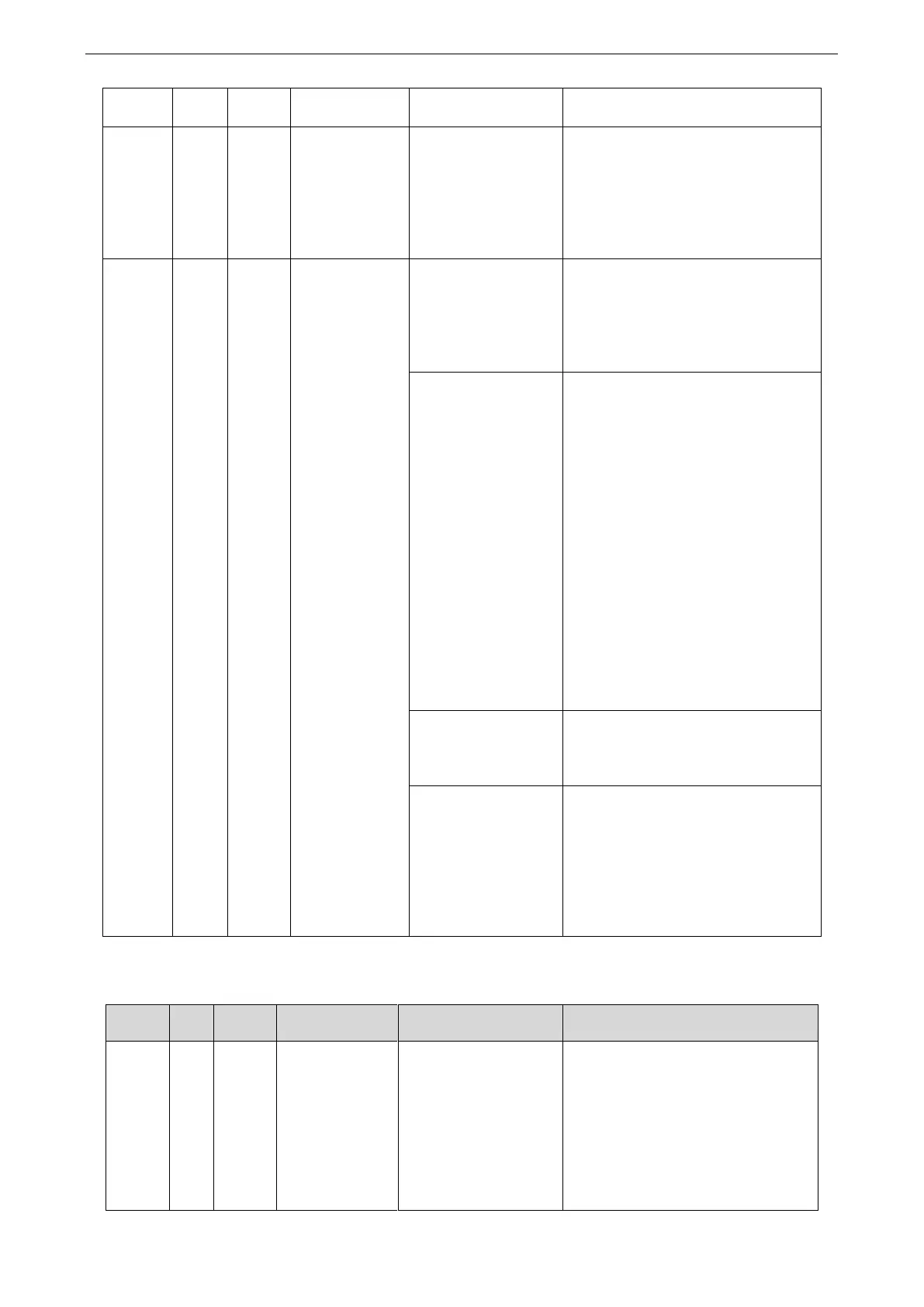

Driver thermal

power overload

Wrong wiring of

encoder cable, power

cable or broken wire

or loose pin of

connector plug

Check the UVW connection of

power cable to see if there is any

phase sequence error.

The multimeter is used to measure

whether all the encoder cable are

on. Check whether the plug is loose,

for machine vibration, whether the

plug has shrinkage pin, virtual

welding, damage.

Loading...

Loading...