77

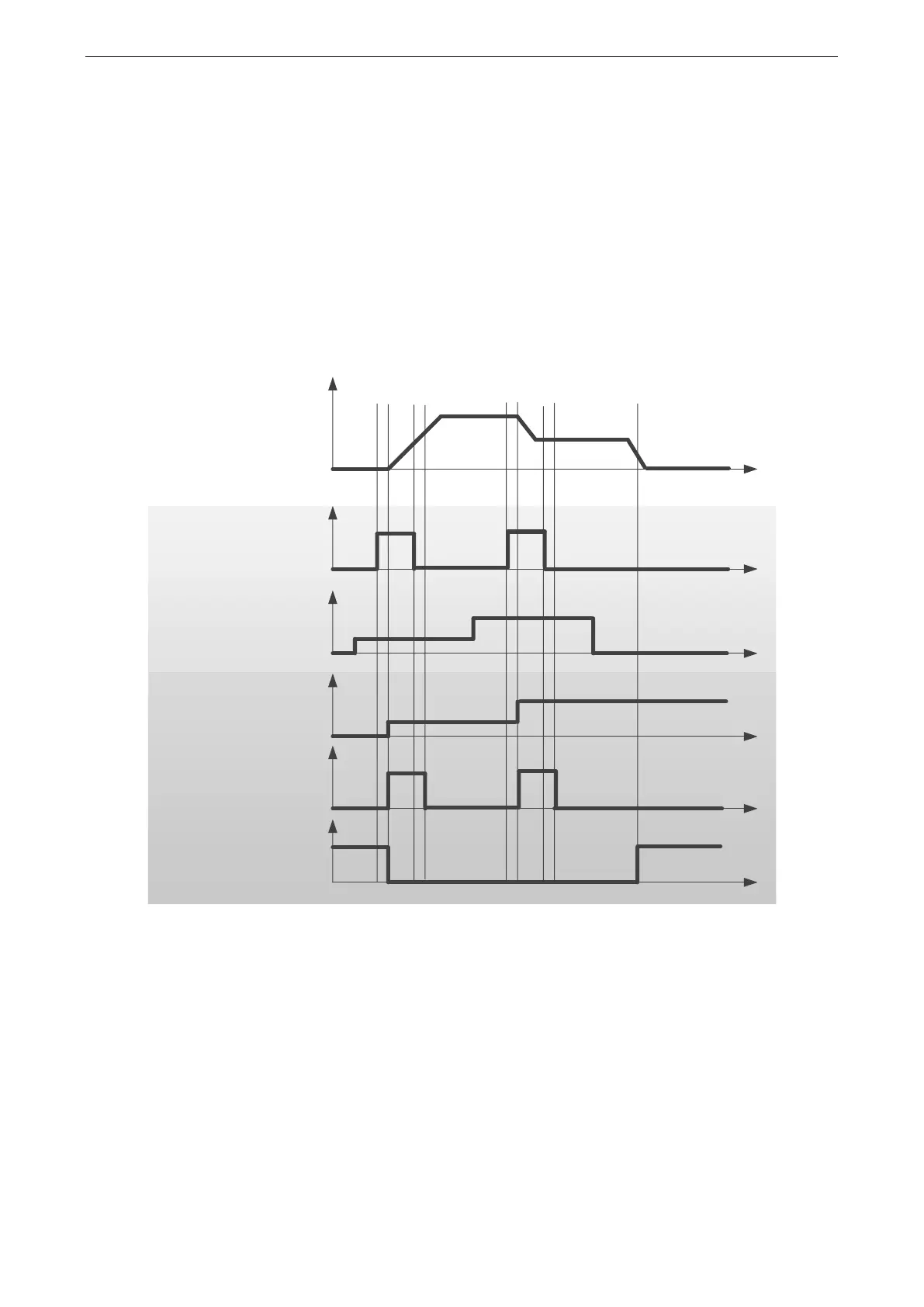

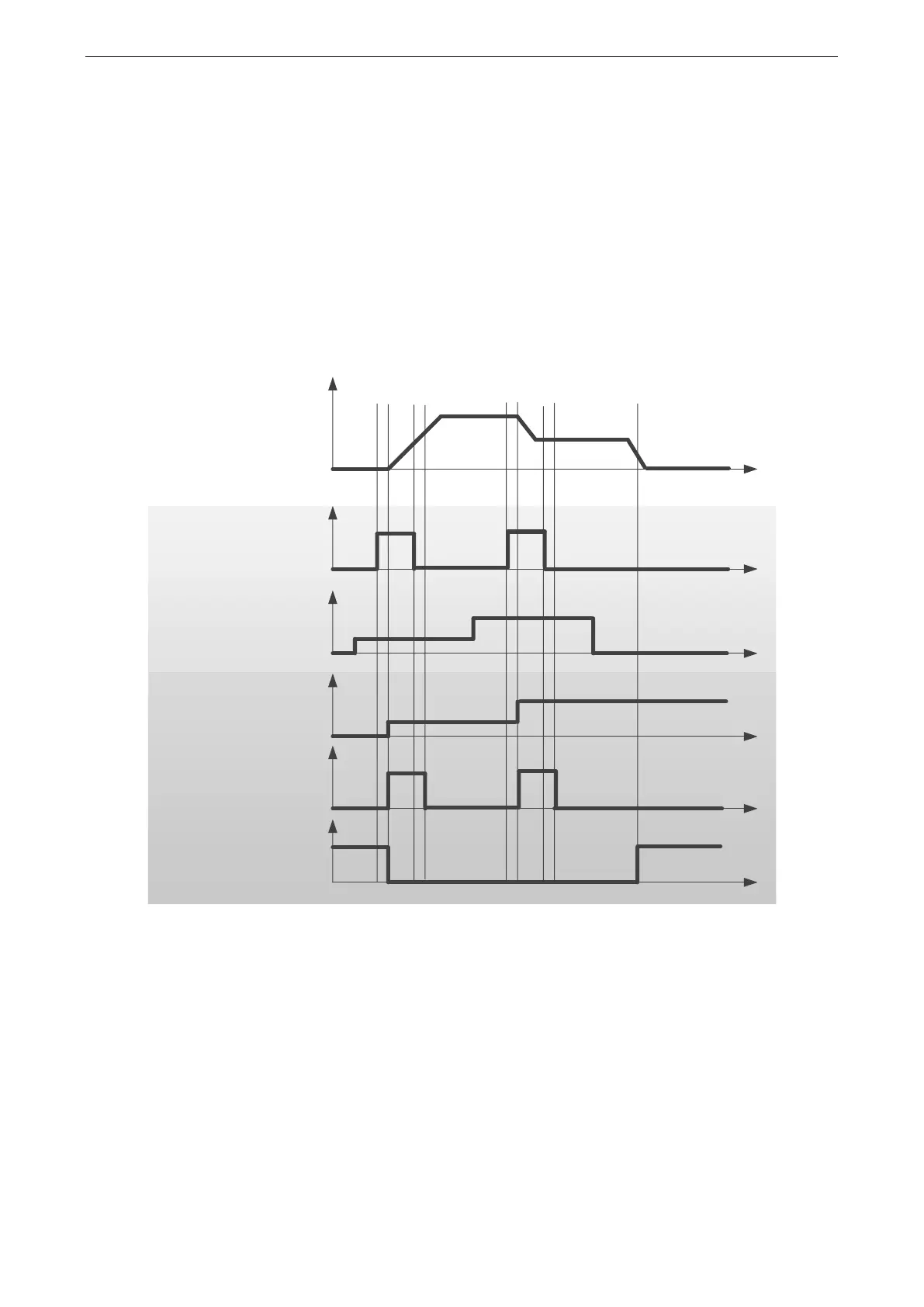

Action 2: Action data change without buffer: single set-point

When 6040h (Controlword) bit5 (change set immediately) is 1, if the positioning action data changed, interrupt

the present positioning action, start the next positioning action at once.

① Main station: confirm 6041h (Statusword) bit12 (set-point acknowledge) is 0, after changing the value of

607Ah (Target position), 6040h (Controlword) bit4 (new set-point) changes from 0 to 1.

Note: do not change acceleration and deceleration at this time.

② Slave station: confirm the rising edge of 6040h (Controlword) bit4 (new set-point) is from 0 to 1. As new

target position and new internal execution speed, 607Ah (Target position) and 6081h (Profile velocity) are

updated immediately. At this time, 6041h (Statusword) bit12 (set-point acknowledge) changes from 0 to 1.

③ Main station: confirm 6041h (Statusword) bit12 (set-point acknowledge) has changed from 0 to 1, 6040h

(Controlword) bit4 (new set-point) returns 0.

④ Slave station: confirm 6040h (Controlword) bit4 (new set-point) is 0, 6041h (Statusword) bit12 (set-point

acknowledge) is 0.

5. Operation examples

Taking the low-voltage servo of Xinje DF3E as an example, the configuration and control process of PP mode are

introduced. Please refer to Appendix 10 for the specific usage method of servo software.

① click [scan] or [add slave station] in CANopen configuration interface, configure the object binding of

TxPDO and RxPDO. Here, several common objects of PP mode are bound. If you have other requirements,

you can add them by yourself and enable the configured PDO. The specific configuration is shown in the

figure below.

Loading...

Loading...