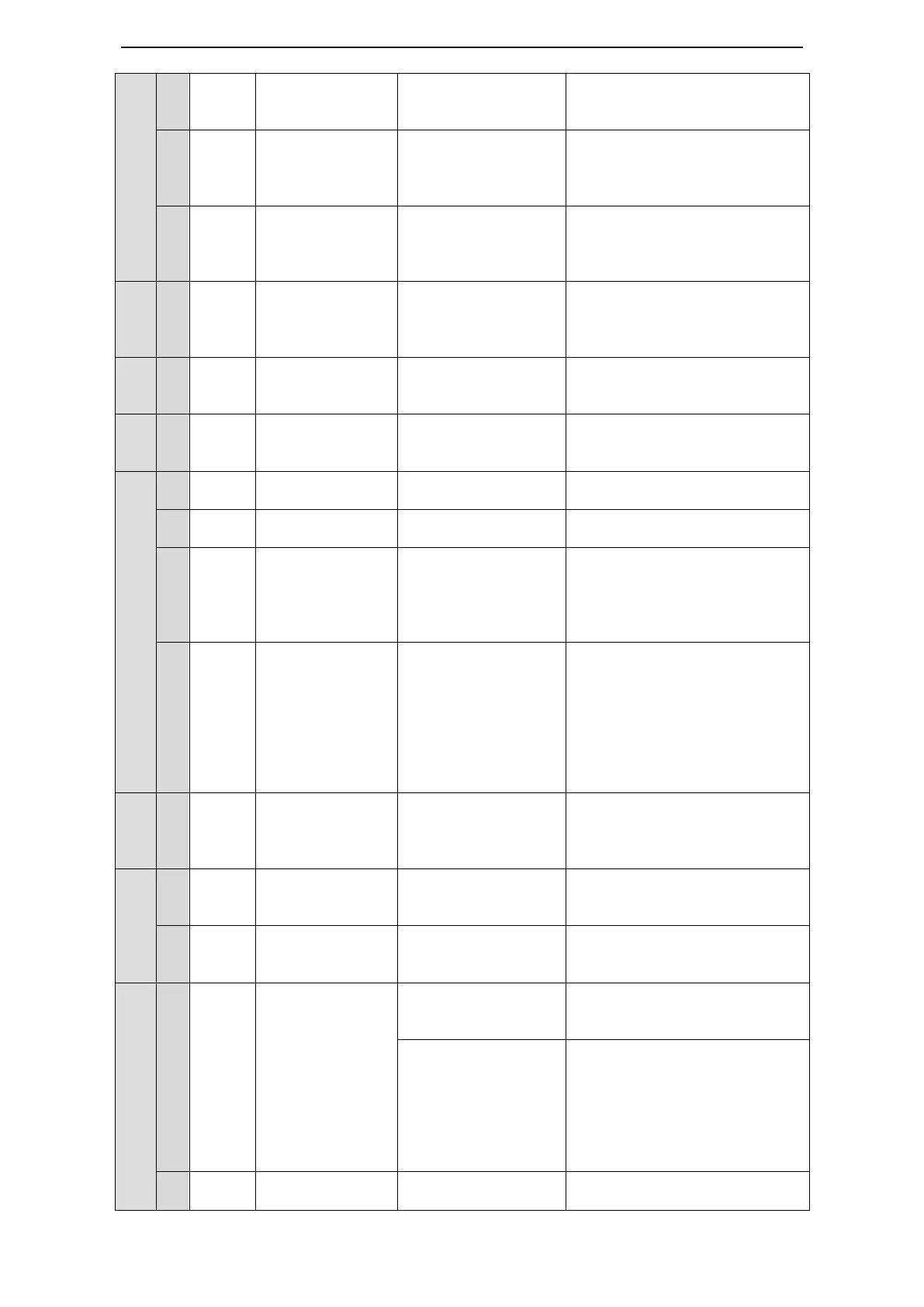

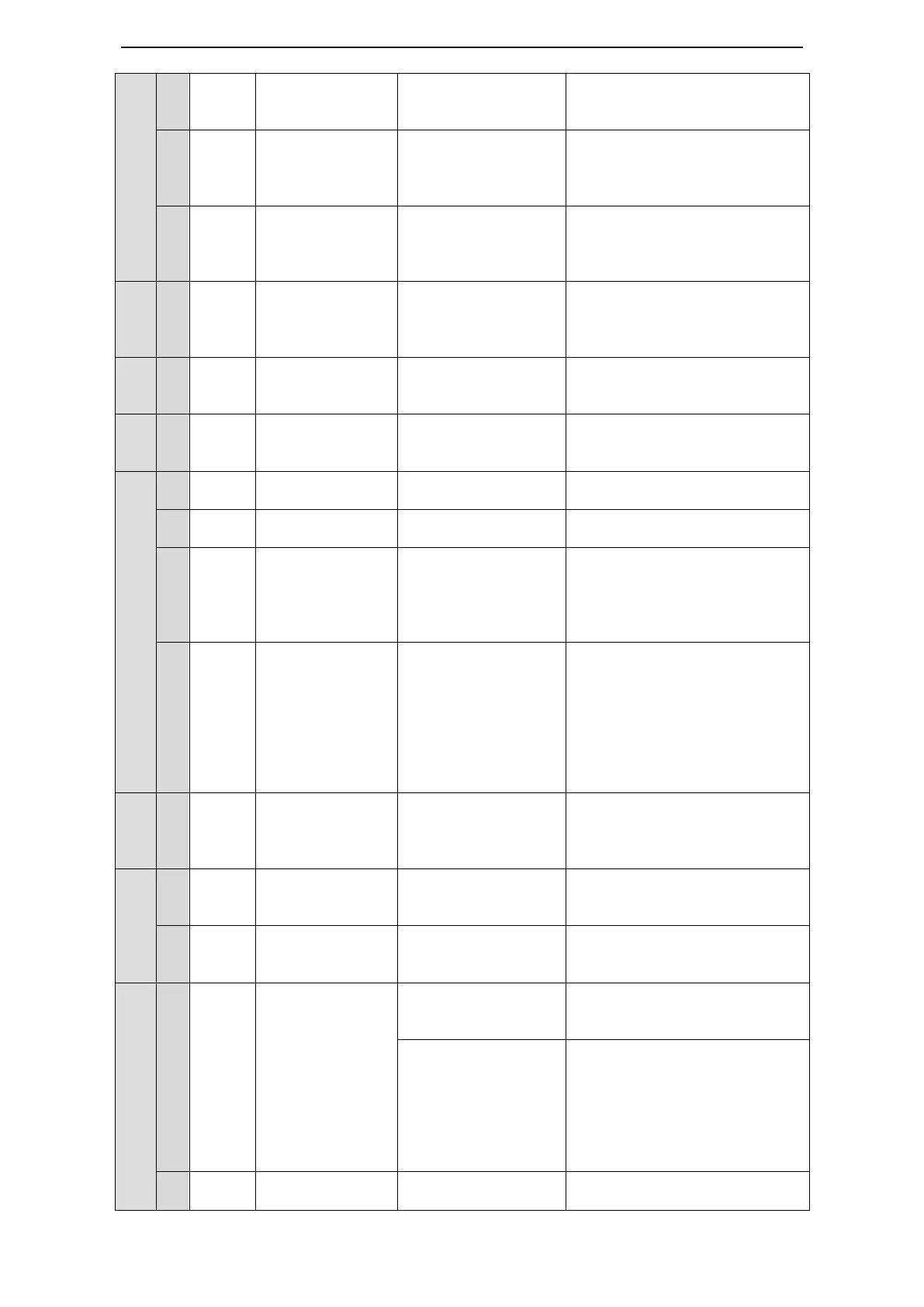

Current sensor

damaged or external

interference too large

Check the ground wiring or

contact us

U phase current

sampling zero

calibration value

error

Current sensor

damaged or external

interference too large

Check the ground wiring or

contact us

V phase current

sampling zero

calibration value

error

Current sensor

damaged or external

interference too large

Check the ground wiring or

contact us

Motor quadrature

encoder AB or

UVW broken

circuit

Cut off the drive power, Check the

wiring, then repower the drive

Motor encoder Z

phase

disconnected

Cut off the drive power, Check the

wiring, then repower the drive

Motor encoder

UVW phase

disconnected

Motor output

power overload

Motor output power

over the rated power

1. Change larger power motor

2. Check the motor shaft wiring

The heating power

overload

1. Change larger power motor

2. Check the motor shaft wiring

The bus capacitor

overload

Power supply not

stable, motor load too

large, cause the bus

capacitor charge

frequently

1. use 3 phase 220V power supply

for 220V drive

2. change larger power motor

locked rotor alarm

(drive version

U2-23=12.24&750

W and down

model support)

Locked rotor time up

to P0-70(unit is

second) and motor

speed lower than

P0-71(unit is 1rpm),

motor present output

torque larger than

P3-28, P3-29

1. monitor U0-02 motor torque,

check if P3-28, P3-29 torque limit

value is reasonable

2. check the mechanical structure

Motor

undervoltage when

running

Bus voltage too low

when running

1. check the power grid voltage

fluctuation

2. wait the bus voltage stable, then

repower

Regenerative

resistor overload

Regenerative resistor

discharging power

over the rated

Change larger power regenerative

resistor

Regenerative

resistor discharge

too long time

Regenerative resistor

connection error or

value too large

Change small value resistor and

check the wiring

Absolute encoder

communication

error

1. Encoder not connect

or contactor not good

Cut off drive power, check

encoder wiring, use multi-meter

test the connection

2. recived encoder data

error, and error time

over encoder error

time register P0-56

value

Not put the encoder wire together

with the strong power supply

cable, install filter at servo drive

power supply input side, install

magnet ring around encoder wire,

far away from large noise

equipment

Absolute encoder

battery voltage

The battery voltage is

lower than 2.75V

Please change new battery when

the servo power is on, the battery

Loading...

Loading...