Maintenance

77

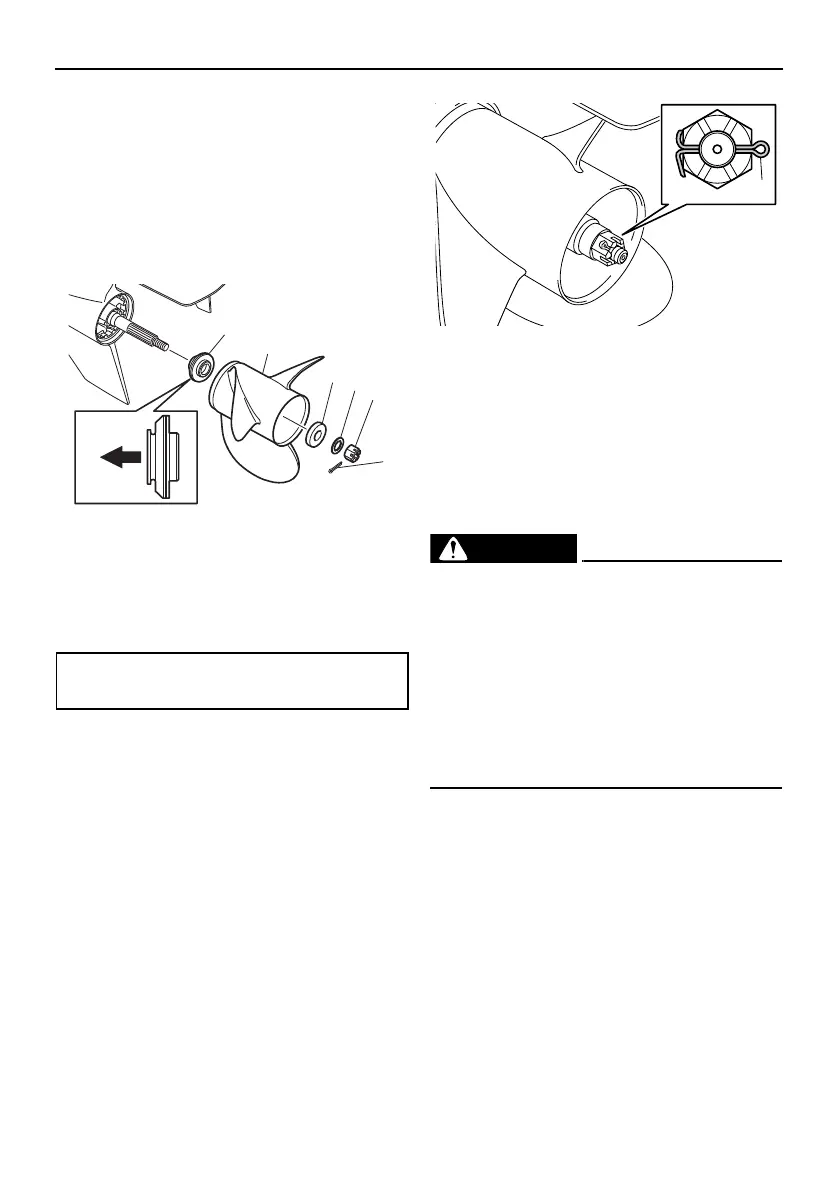

thrust washer before installing the

propeller. Otherwise, the lower case

and propeller boss could be damaged.

[ECM01882]

3. Install the spacer, washer, and propeller

nut. Tighten the propeller nut to the

specified torque.

4. Align the propeller nut slot with the pro-

peller shaft hole. Insert a new cotter pin

in the hole and bend the cotter pin ends.

NOTICE: Do not reuse the cotter pin.

Otherwise, the propeller can come off

during operation.

[ECM01892]

If the propeller nut slot does not align with the

propeller shaft hole after tightening the pro-

peller nut to the specified torque, tighten the

nut further to align the slot with the hole.

EMU47100

Changing gear oil

EWM00801

Be sure the outboard motor is securely

fastened to the transom or a stable

stand. You could be severely injured if

the outboard motor falls on you.

Never get under the lower unit while it is

tilted, even when the tilt support lever or

knob is locked. Severe injury could oc-

cur if the outboard motor accidentally

falls.

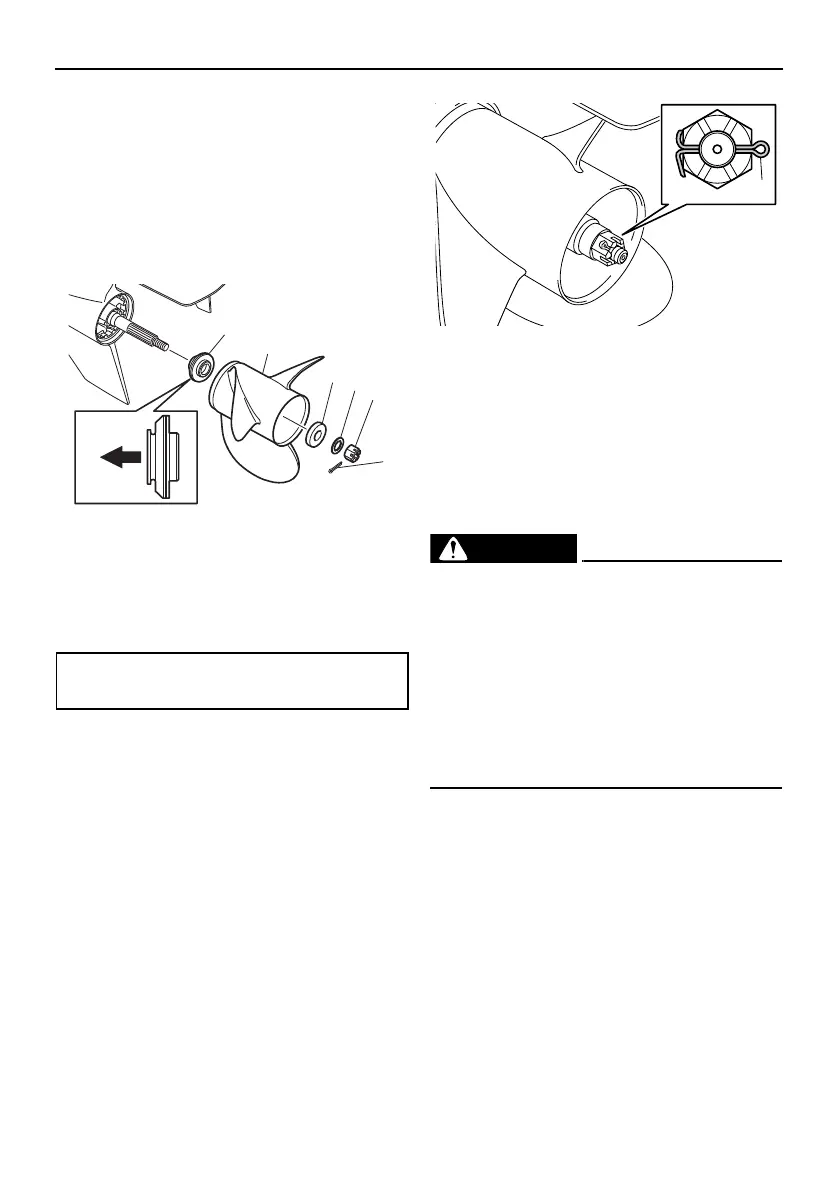

1. Tilt the outboard motor so that the gear

oil drain screw is at the lowest point pos-

sible.

2. Place a suitable container under the gear

case.

3. Remove the gear oil drain screw and

gasket. The screw is magnetic so a small

quantity of metal particles on the end of

the screw is normal. Simply remove

them. NOTI CE : If there is an excessive

quantity of metal particles on the

1. Cotter pin

2. Propeller nut

3. Washer

4. Spacer

5. Propeller

6. Thrust washer

Propeller nut tightening torque:

54 N·m (5.51 kgf·m, 39.8 lb·ft)

1. Cotter pin

U63P7KE0.book Page 77 Wednesday, November 29, 2017 11:06 AM

Loading...

Loading...