Chapter 2 Basic Engine

5. Piston and Piston Pins

mm (in.)

Standard

Wear

limit

First

piston

ring

Groove

width

2.095 -2.110

(0.0825 - 0.0831)

-

First

piston

ring

Ring

width

1.975- 1.990

(0.0778 - 0.0783)

First

piston

ring

Groove

and

ring clearance

0.105-0.135

(0.0041 -0.0053)

0.15

(0.0059)

Second

piston

ring

Groove

width

2.045 - 2.060

(0.0805-0.0811)

-

Second

piston

ring

Ring

width

1.975- 1.990

(0.0778 - 0.0783)

-

Second

piston

ring

Groove

and

ring clearance

0.055 - 0.085

(0.0022 - 0.0035)

0.15

(0.0059)

Oil

ring

Groove

width

3.020 - 3.035

(0.1189-0.1195)

-

Oil

ring

Ring

width

2.92 - 2.99

(0.1169-0.1177)

-

Oil

ring

Groove

and

ring clearance

0.030 - 0.065

(0.0012-0.0026)

0.15

(0.0059)

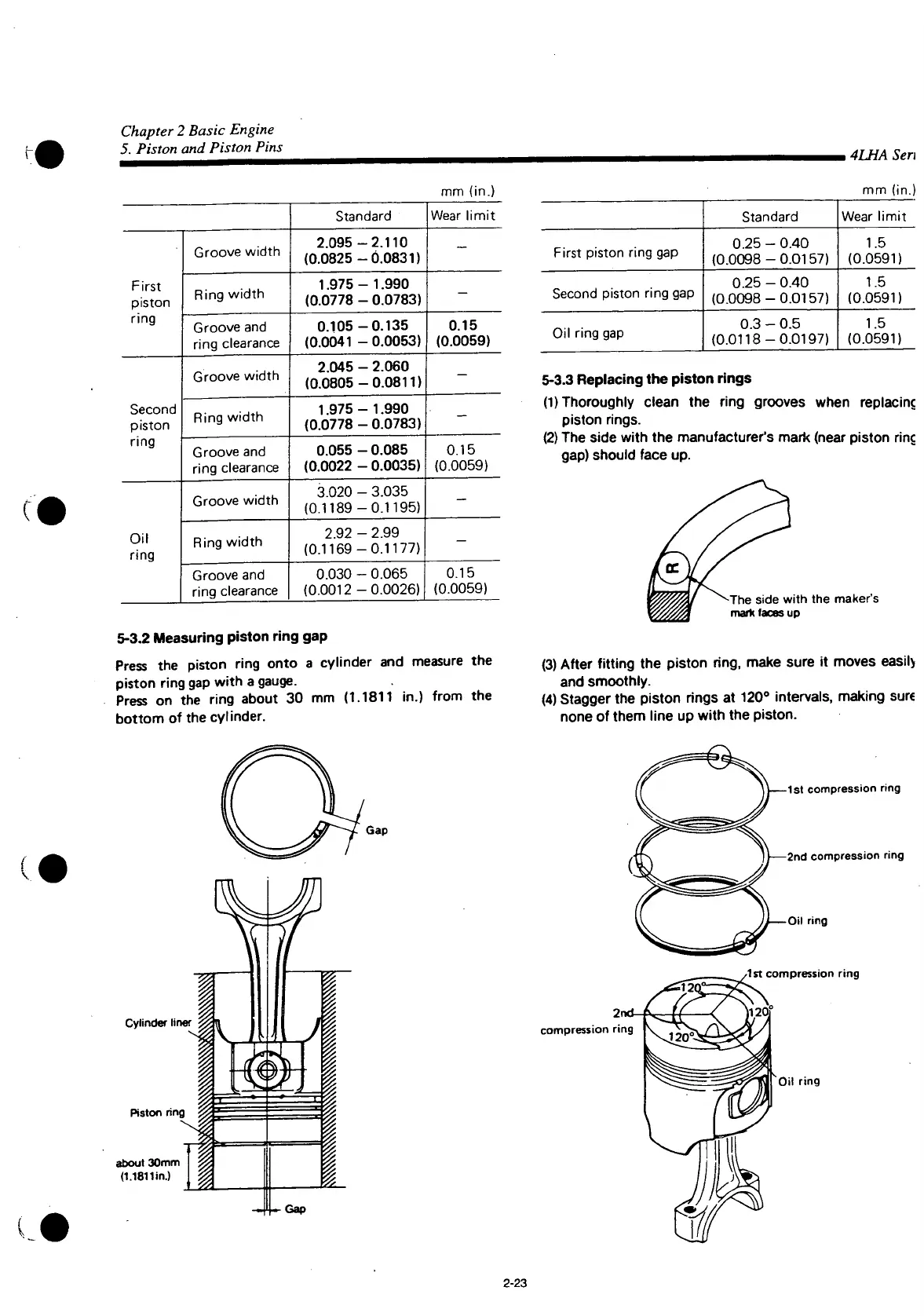

5-3.2

Measuring

piston

ring

gap

Press

the piston ring onto a cylinder and measure the

piston ring gap

with

a gauge.

Press

on the ring about 30 mm (1.1811 in.) from the

bottom of the cylinder.

Gap

about 30mm

(1.181

lin.)

,

4LHA Sen

mm (in.)

Standard

Wear

limit

First

piston ring gap

0.25 - 0.40

(0.0098 - 0.0157)

1.5

(0.0591)

Second

piston ring gap

0.25 - 0.40

(0.0098 - 0.0157)

1.5

(0.0591)

Oil

ring gap

0.3 - 0.5

(0.0118-0.0197)

1.5

(0.0591)

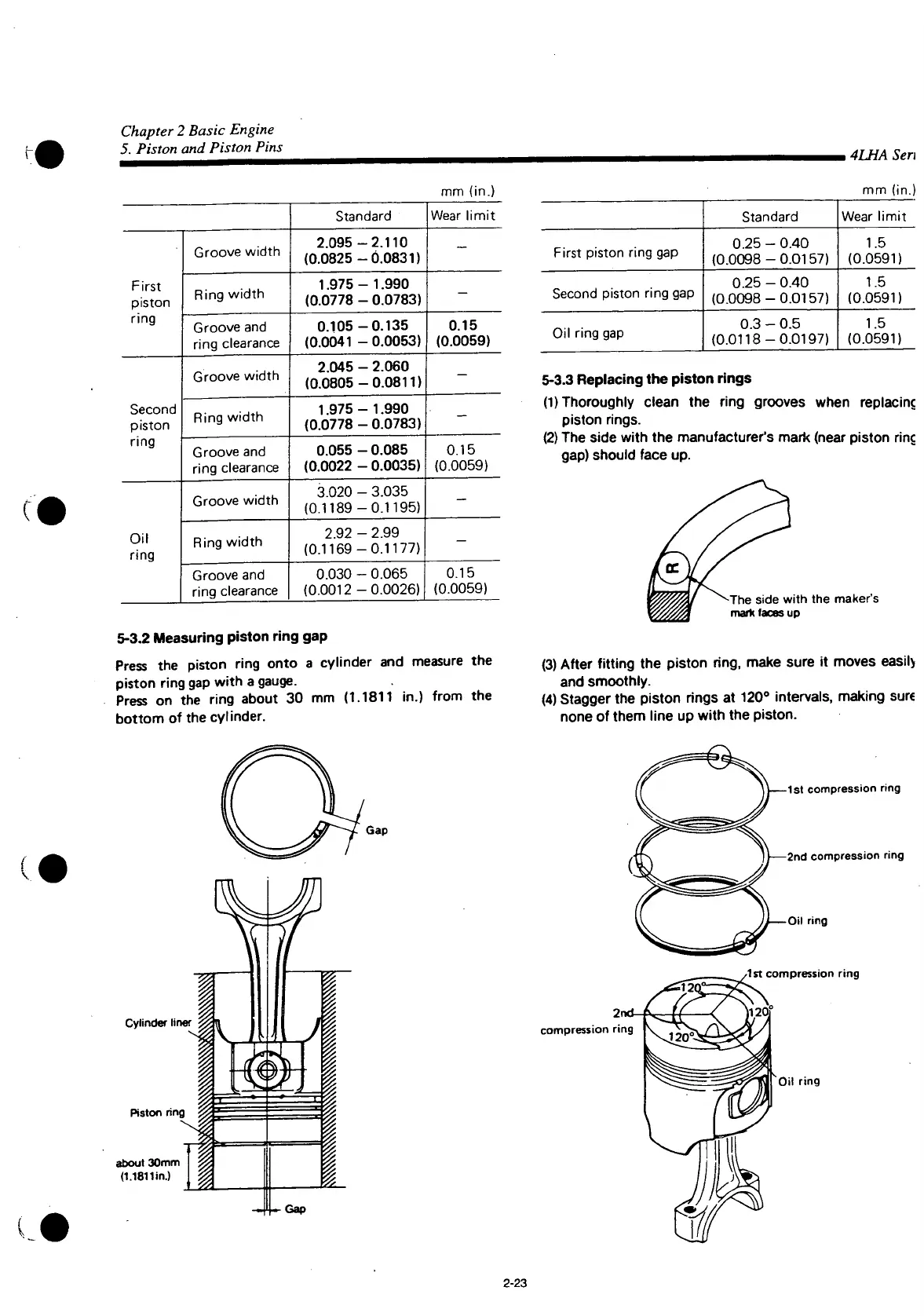

5-3.3 Replacing the piston rings

(1) Thoroughly clean the ring grooves when replacing

piston rings.

(2) The side

with

the manufacturer's mark (near piston ring

gap) should face up.

The

side

with

the maker's

mark faces up

(3) After

fitting

the piston ring, make sure it moves easily

and

smoothly.

(4) Stagger the piston rings at 120° intervals, making sure

none of them line up

with

the piston.

1st compression ring

2nd compression ring

Oil

ring

1st compression ring

2nd

compression

ring

Oil

ring

2-23

Loading...

Loading...