Chapter 3 Fuel Injection Equipment

1. Fuel Supply System

4LHA Series

1-4

Injection

volume

control

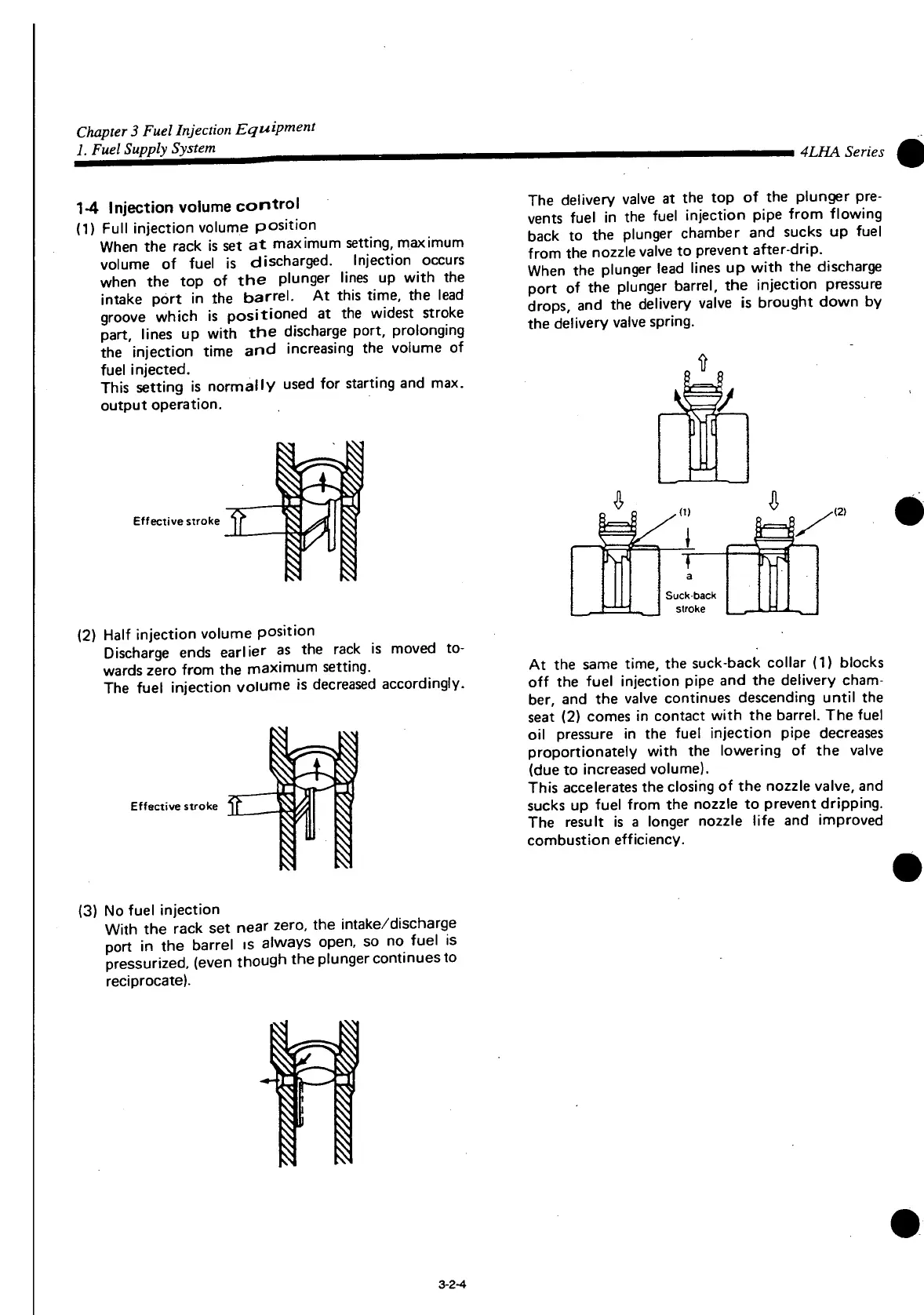

(1) Full injection volume position

When

the rack is set at maximum setting, maximum

volume of fuel is discharged.

Injection

occurs

when the top of the plunger lines up

with

the

intake

port

in the barrel. At this time, the lead

groove which is positioned at the widest stroke

part, lines up

with

the discharge

port,

prolonging

the injection time and increasing the volume of

fuel injected.

This

setting is normally used for starting and max.

output

operation.

Effective stroke

(2) Half injection volume position

Discharge

ends earlier as the rack is moved to-

wards zero from the maximum setting.

The

fuel injection volume is decreased accordingly.

Effective stroke

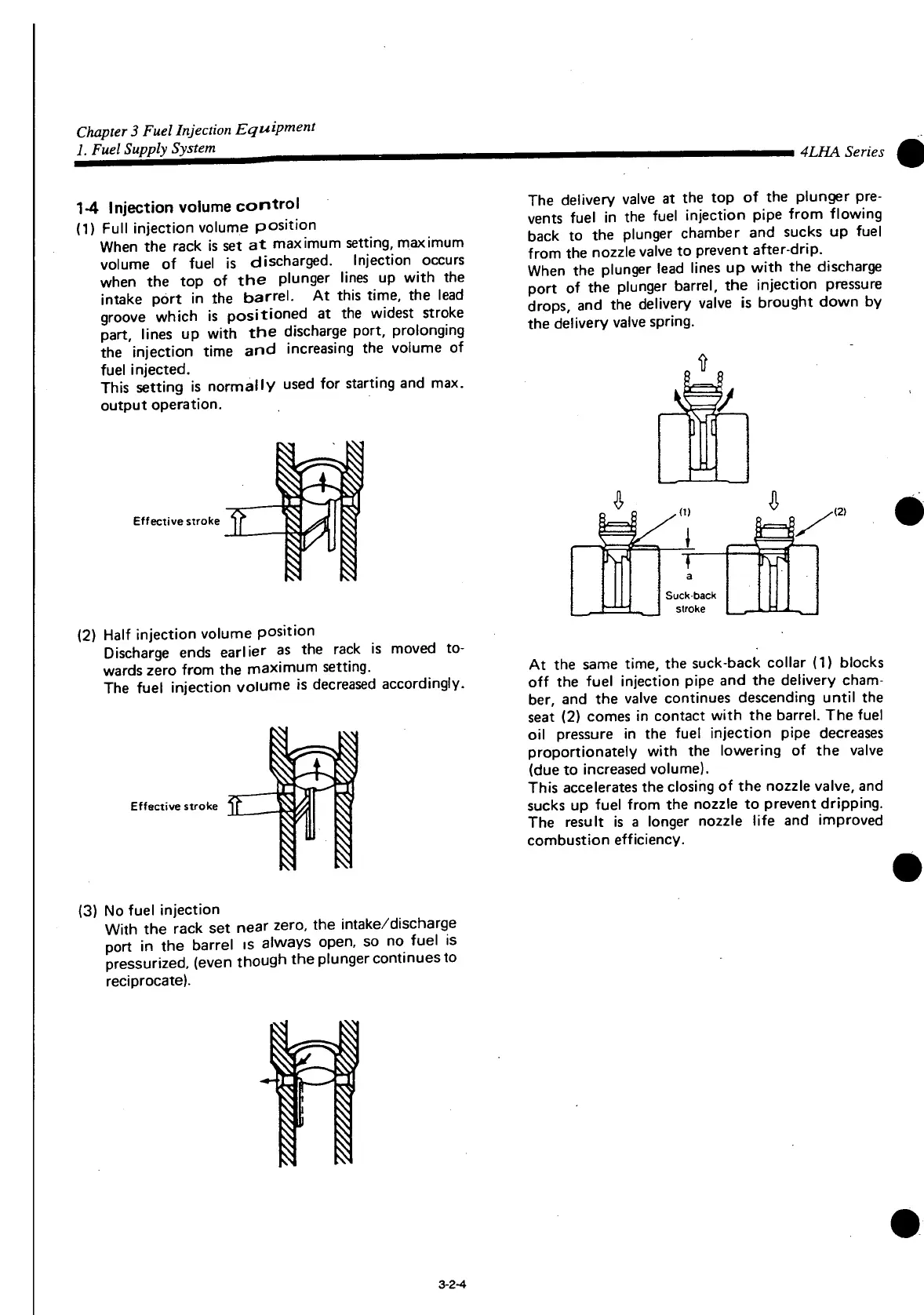

The

delivery valve at the top of the plunger pre-

vents fuel in the fuel injection pipe from flowing

back

to the plunger chamber and sucks up fuel

from the nozzle valve to prevent after-drip.

When

the plunger lead lines up

with

the discharge

port

of the plunger barrel, the injection pressure

drops,

and the delivery valve is brought down by

the delivery valve spring.

«1.

Si

IT

I

V

*

4

1=1

Suck-back

stroke

A2)

At the same time, the suck-back collar (1) blocks

off the fuel injection pipe and the delivery cham-

ber, and the valve continues descending

until

the

seat

(2) comes in contact

with

the barrel. The fuel

oil pressure in the fuel injection pipe decreases

proportionately

with

the lowering of the valve

(due to increased volume).

This

accelerates the closing of the nozzle valve, and

sucks

up fuel from the nozzle to prevent dripping.

The

result is a longer nozzle life and improved

combustion efficiency.

(3) No fuel injection

With the rack set near zero, the intake/discharge

port

in the barrel is always open, so no fuel is

pressurized,

(even though the plunger continues to

reciprocate).

3-2-4

Loading...

Loading...