Chapter 9 Electrical System

3. Starter Motor

M4LHA Ser

3.

Starter

Motor

The starter motor is installed on the flywheel housing.

When the starting

button

is pushed, the starter motor

pinion flies out and engages the ring gear of the flywheel.

Then the main contact is

closed,

current flows, and the

engine is started.

After the engine starts, the pinion automatically returns to

its initial position when the starting

button

is released.

Once

the; engine starts, the starting

button

should be

released

immediately. Otherwise, the starter motor may be

damaged or burned out.

2

Features

(1) The starter motor is compact and produces high ou

through high speed revolutions. It has increased toi

with

employing a reduction gear to reduce the sp

between the armature and the pinion.

(2) The use of ball bearings at the armature shaft

(front

rear sides) and the needle bearings for the gear s

(rear side) has boosted the durability of the starter

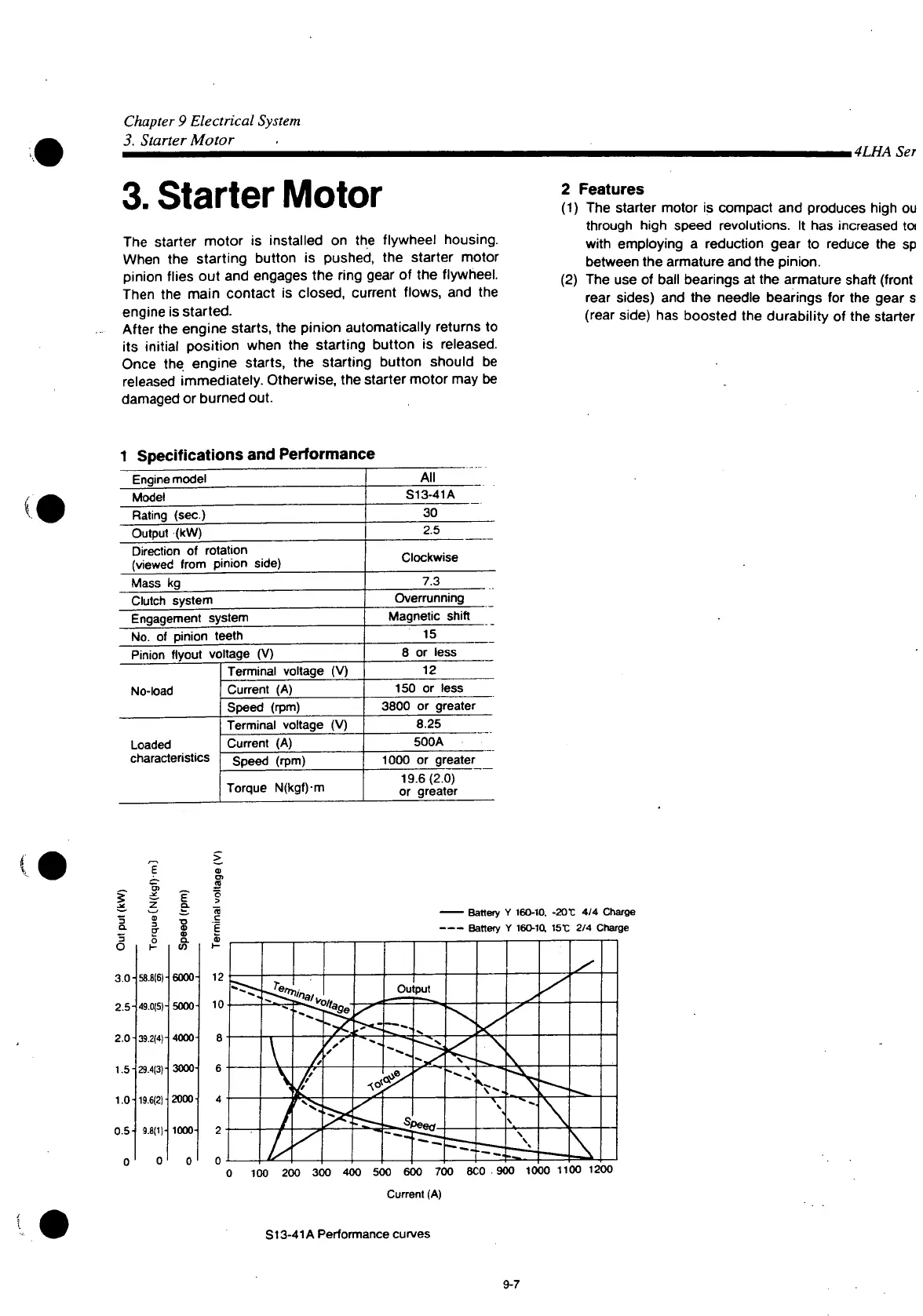

1

Specifications

and

Performance

Engine

model

All

Model

S13-41A

Rating (sec.)

30

Output (kW)

2.5

Direction of rotation

(viewed from pinion side)

Clockwise

Mass

kg

7.3

Clutch

system

Overrunning

Engagement system

Magnetic

shift

No.

of pinion teeth

15

Pinion

flyout

voltage (V)

8 or

less

No-load

Terminal voltage (V)

12

No-load

Current (A)

150 or

less

No-load

Speed

(rpm)

3800 or greater

Loaded

characteristics

Terminal voltage (V)

8.25

Loaded

characteristics

Current (A)

500A

Loaded

characteristics

Speed

(rpm)

1000 or greater

Loaded

characteristics

Torque N(kgf) m

19.6 (2.0)

or greater

i

f i

I I I

3

« «

o

3.0

2.5

2.0

1.5

1.0

0.5

0

58.8(6)

49.0(5)

39.2(4)-

29.4(3)

19.6(2)

9.8(1)

0

6000

5000

4000

2000

1000

0

12

10

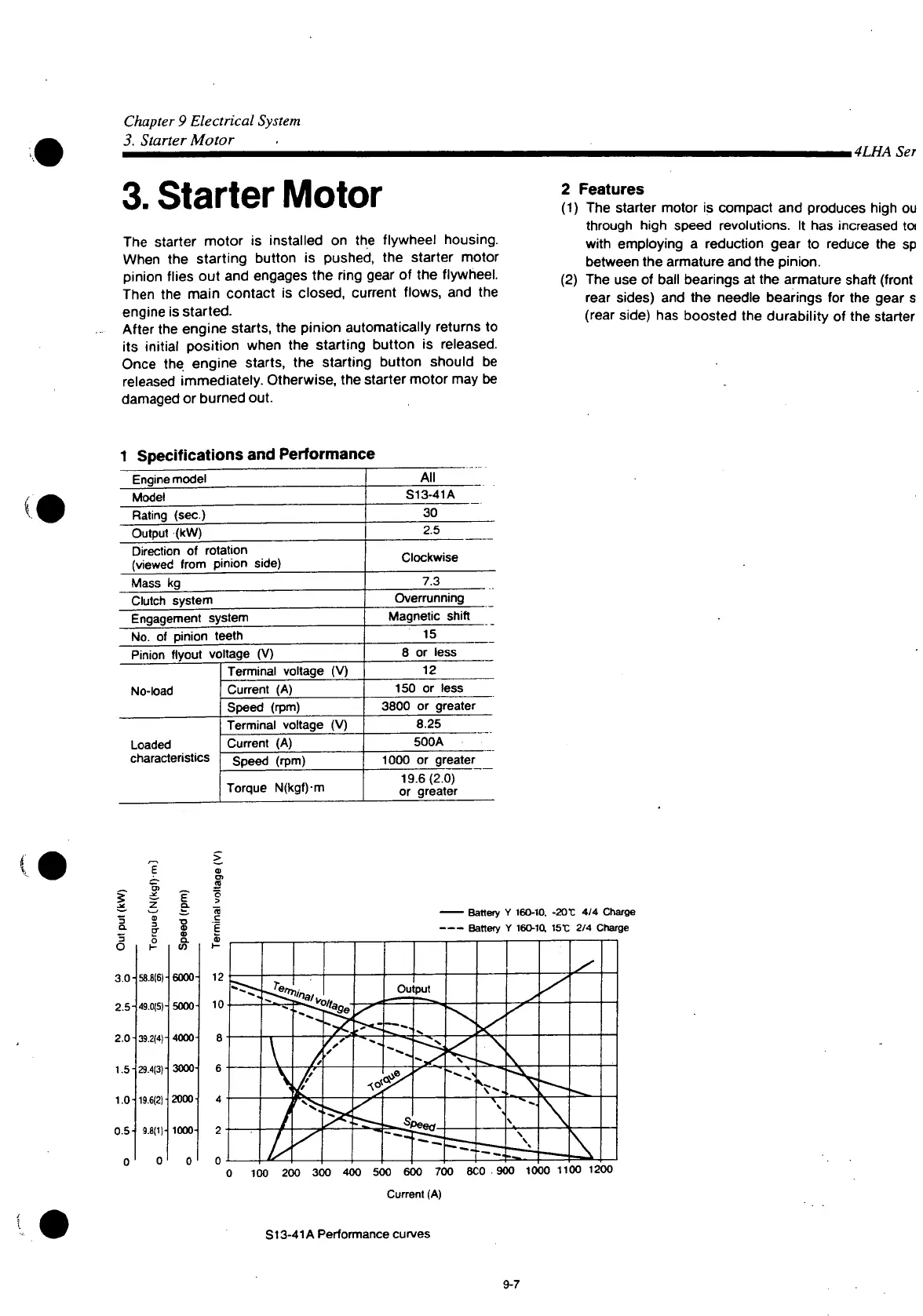

Battery Y 160-10, -201 4/4 Charge

Battery Y 160-ia

15

"C

2/4 Charge

Ou

put

—

—

<

//

/

—

.—

\

\

ft

ft

•

V.

- S/

\

\

\

\

\

\

0 100 200 300 400 500 600 700 8C0 900 1000 1100 1200

Current (A)

S13-41A

Performance curves

9-7

Loading...

Loading...