Chapter 9 Electrical System

3. Starter Motor

i

4LHA Series

6

Inspection

6.1

Armature

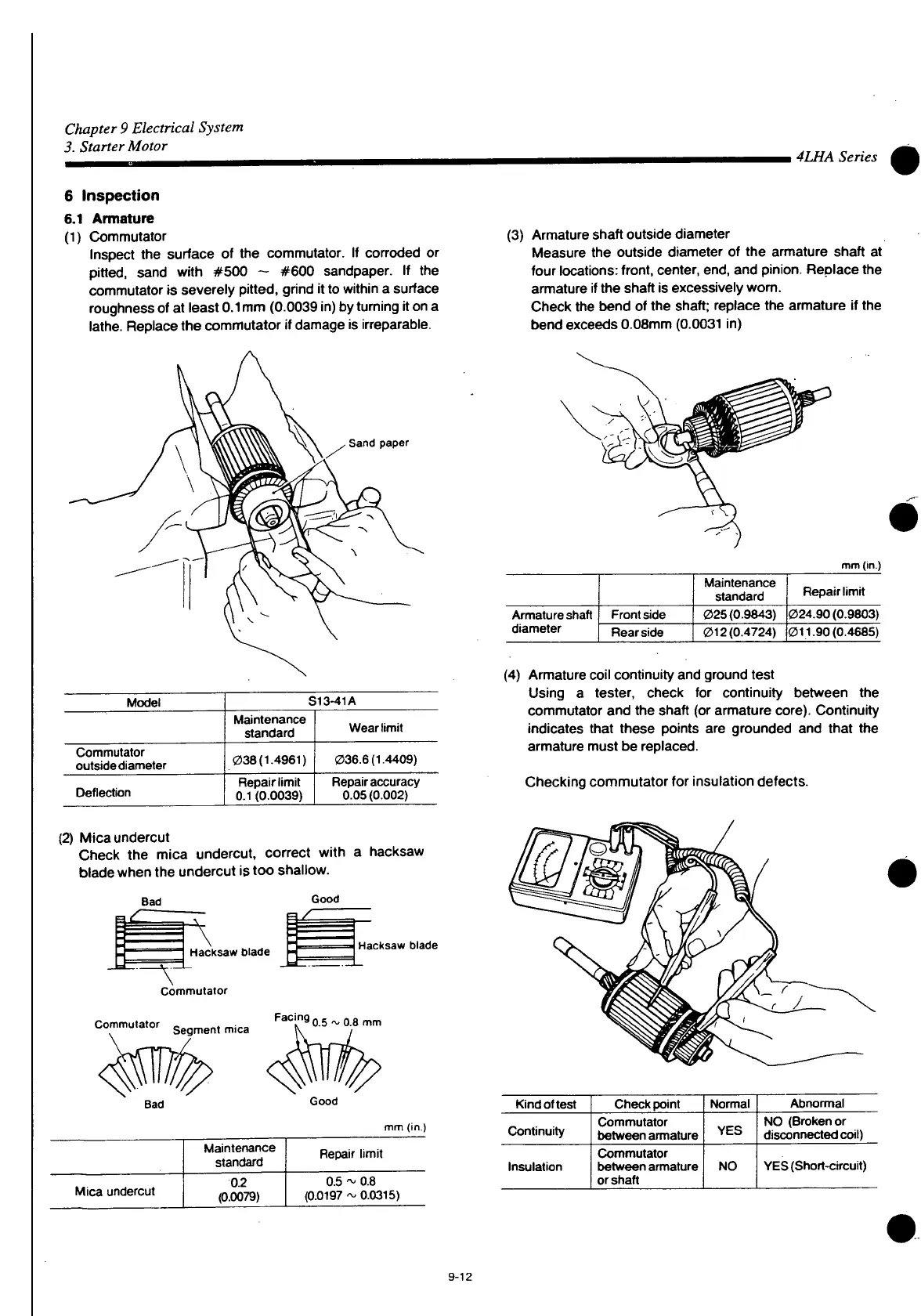

(1) Commutator

Inspect the surface of the commutator. If corroded or

pitted, sand

with

#500

~

#600

sandpaper. If the

commutator is severely pitted, grind it to

within

a surface

roughness

of at least 0.1 mm (0.0039 in) by

turning

it on a

lathe.

Replace

the commutator if damage is irreparable.

Sand

paper

Model

SI

3-41A

Maintenance

standard

Wear

limit

Commutator

outside diameter

038(1.4961)

036.6(1.4409)

Deflection

Repair

limit

0.1 (0.0039)

Repair

accuracy

0.05(0.002)

(2)

Mica

undercut

Check

the mica undercut, correct

with

a hacksaw

blade

when the undercut is too shallow.

Bad

Hacksaw

blade

Good

Hacksaw

blade

Commutator

Commutator

Segment mica

FaCi

"

9

0.5 ~ 0.8 mm

Bad

Good

mm (in.)

Maintenance

standard

Repair

limit

Mica

undercut

0.2

(0.0079)

0.5 ~ 0.8

(0.0197 ~ 0.0315)

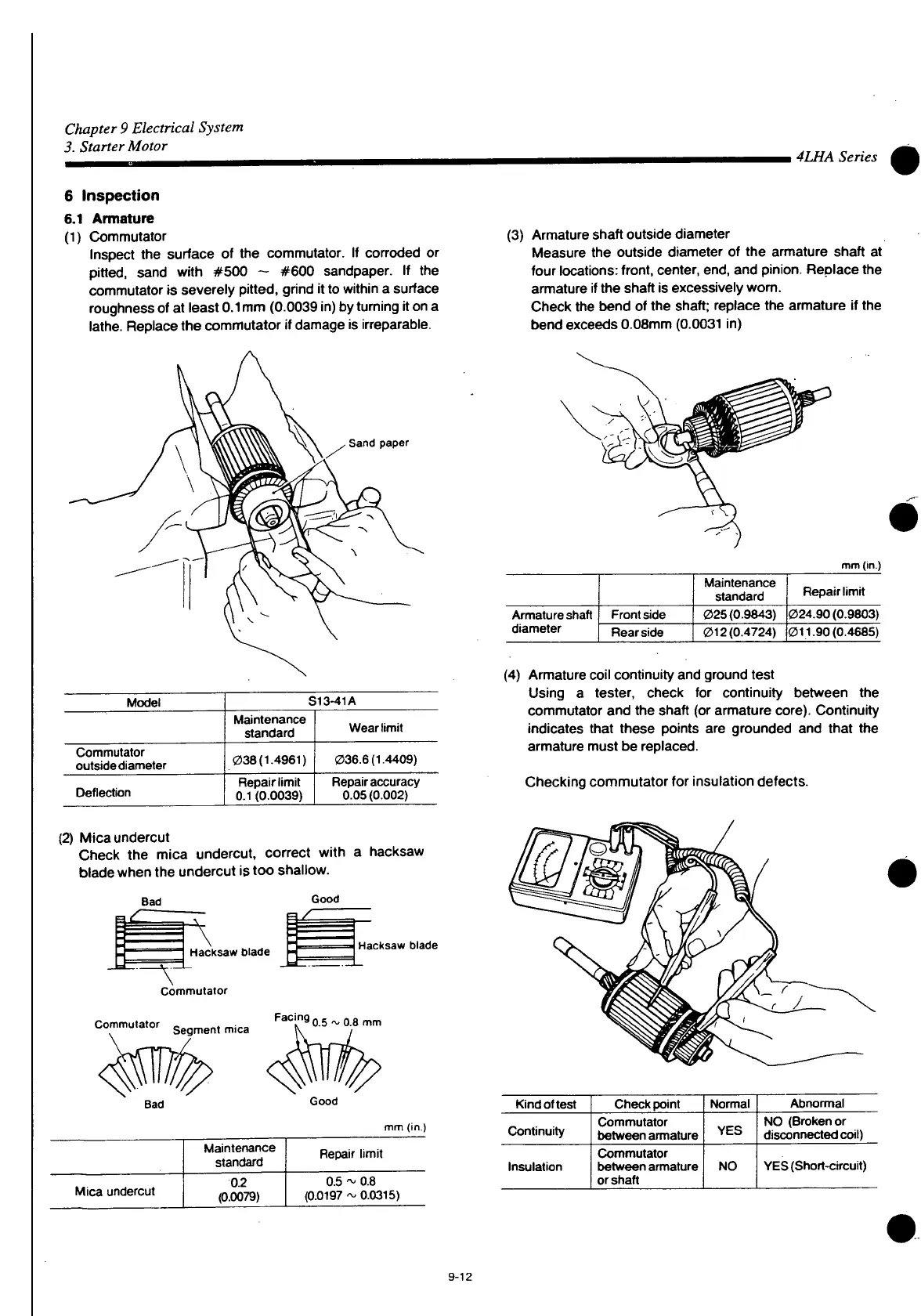

(3)

Armature shaft outside diameter

Measure

the outside diameter of the armature shaft at

four

locations:

front,

center,

end,

and pinion.

Replace

the

armature if the shaft is

excessively

wom.

Check

the bend of the shaft; replace the armature if the

bend

exceeds

0.08mm

(0.0031

in)

mm

(in.)

Maintenance

standard

Repair

limit

Armature shaft

diameter

Front side 025(0.9843)

024.90(0.9803)

Armature shaft

diameter

Rear

side

012(0.4724)

011.90(0.4685)

(4) Armature coil continuity and ground test

Using

a tester, check for continuity between the

commutator and the shaft (or armature core). Continuity

indicates

that

these points are grounded and

that

the

armature must be replaced.

Checking

commutator for insulation defects.

Kind

oftest

Checkpoint

Normal

Abnormal

Continuity

Commutator

between armature

YES

NO

(Broken or

disconnected

coil)

Insulation

Commutator

between armature

or shaft

NO

YES

(Short-circuit)

9-12

Loading...

Loading...