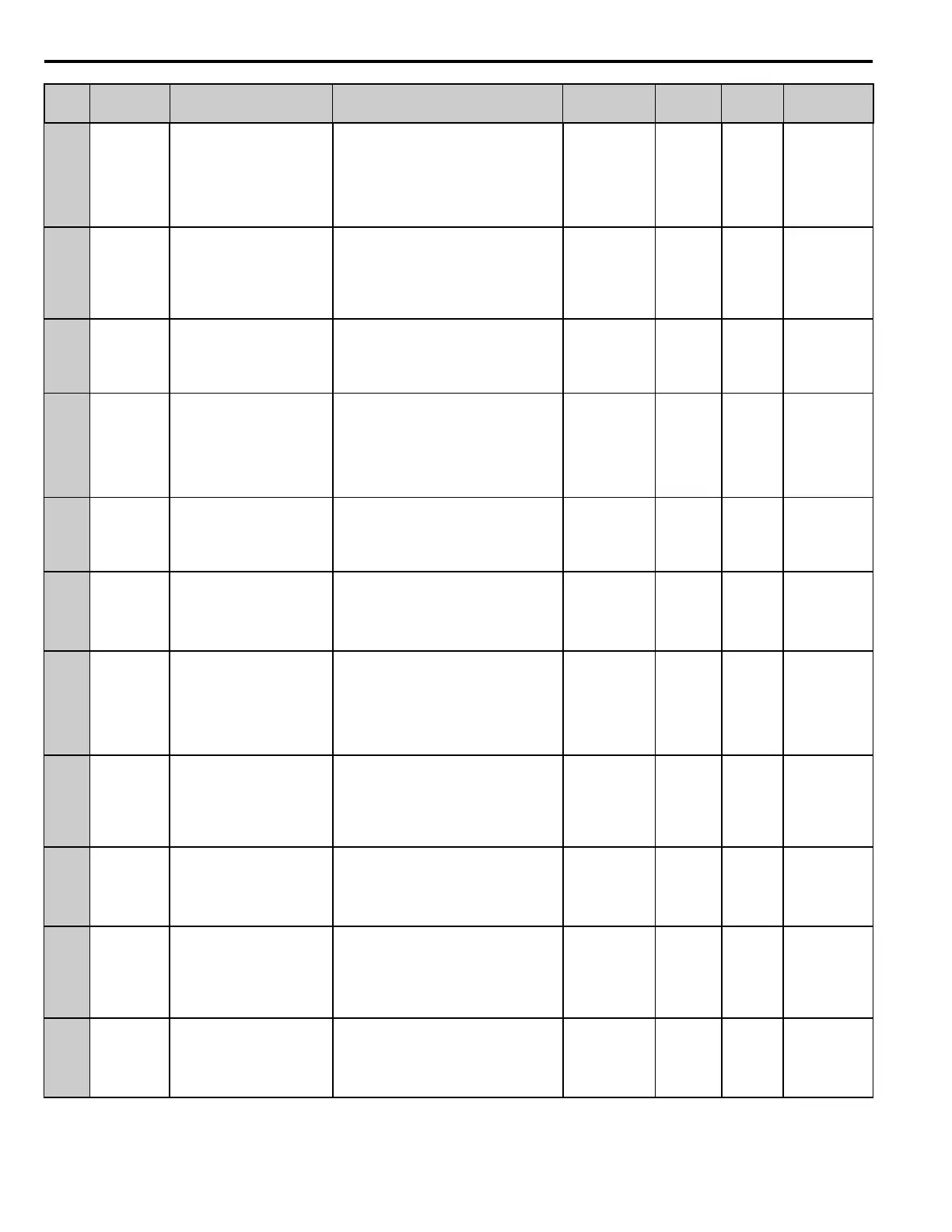

2 Spindle Orientation

12 YASKAWA TM.A1000SW.063 Spindle Orientation A1000 Custom Software Supplement

P1-10 0609h

Orientation Encoder Card Selection

ORT Enc Select

This parameter selects which PG option card is used

for orientation.

0: CN5-C

1: CN5-B

Note: When using only one PG option card, P1-10

must be set to 0.

0 to 1 0 No – – – Y– – N

P1-11 061Eh

Orientation Deceleration Selection

ORT Dec Sel

This parameter selects whether the drive’s C1-0

Deceleration Time is overridden by the P1-12

Orientation Deceleration Time once the drive

reaches the P1-01 Orient Speed.

0: Disabled

1: Enabled

0 to 1 0 No – – – Y– – N

P1-12 061Fh

Orientation Deceleration Time

ORT Dec Time

The Orientation Deceleration Time parameter sets

the time to decelerate from the maximum output

frequency (E1-04) to 0 Hz. Refer to Area A:

Deceleration on page 19

0.00 to 600.00 sec 10.00 Yes – – – Y– – N

P1-13 0620h

Spindle Proximity Sensor

Orientation Enable

Prox Sens Enable

This parameter selects whether or not the drive is

configured with a proximity sensor as described in

Configuration 3. Setting parameter P1-13 = 1 causes

the drive to recognize the values set in proximity

sensor parameters P1-14 and P1-15.

0: Disabled

1: Enabled

0 to 1 0 No – – – Y– – N

P1-14 0621h

Proximity Sensor Pulse Width

Prox Pulse Width

This parameter defines the pulse width of the

proximity sensor at the P1-02 Creep Speed,

measured in elapsed encoder counts.

0 to 60000 Cnts 0 No – – – Y– – N

P1-15 0622h

Proximity Sensor Pulse State

Prox Pulse State

This parameter defines whether or not the proximity

sensor is a Normally Open (rising edge) or

Normally Closed (falling edge).

0: Normally Open

1: Normally Closed

0 to 1 0 No – – – Y– – N

P2-01 060Ah

Marker Offset Selection

MarkerOffset Sel

This parameter determines how the orientation

position offset from the marker pulse is determined.

0: Digital Input

1: Sequential

2: Memobus COM

Refer to Orient Position Offset Selection on

page 25.

0 to 2 0 No – – – Y– – N

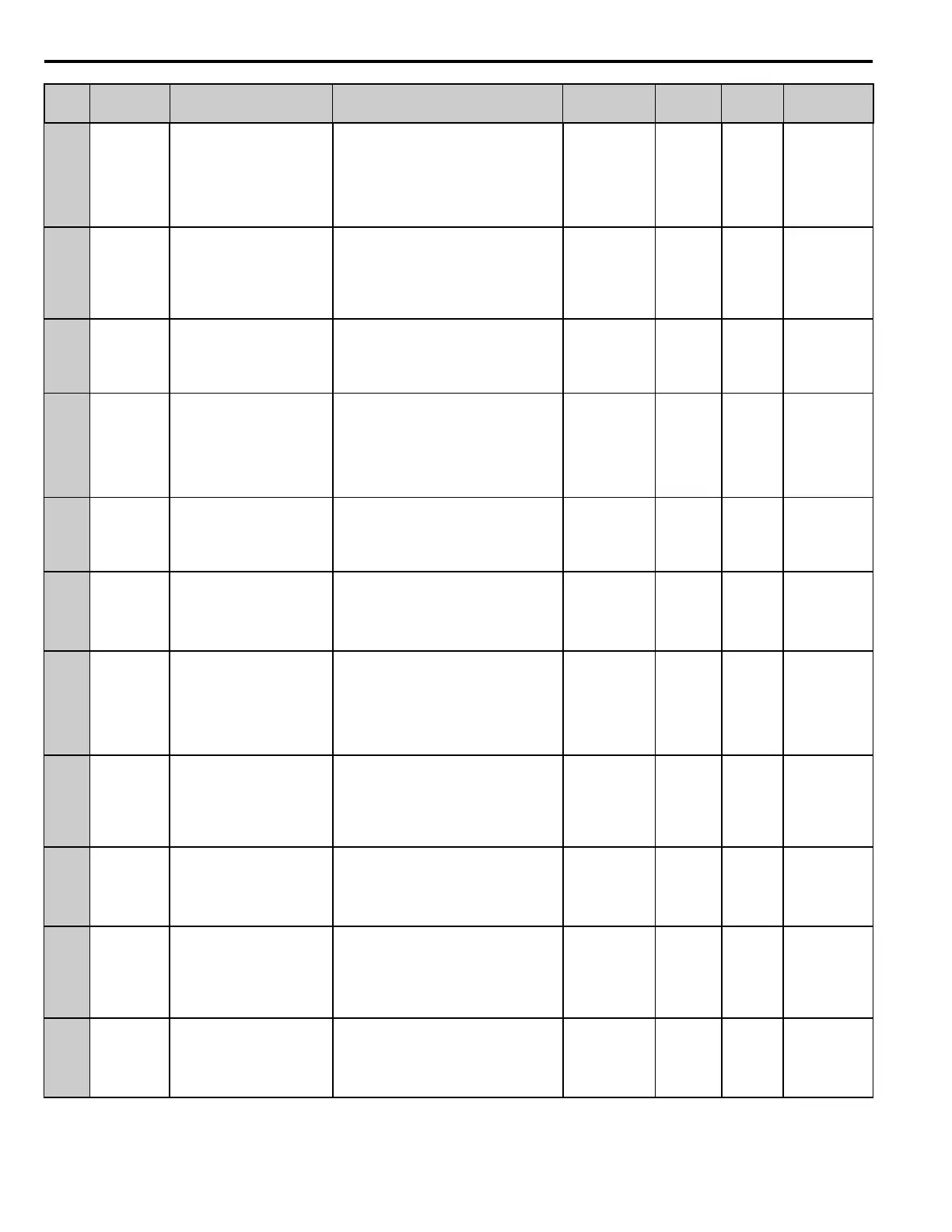

P2-02 060Bh

Marker Offset 1

Marker Offset 1

This parameter, along with parameters P2-03, P2-

04, and P2-05, sets the orientation (or stopped)

position of the machine. P2-01 governs when P2-02

is active. Refer to Orient Position Offset Selection

on page 25.

Note: Counts = Encoder PPR x 4.

0 to 65535 Cnts 0 No – – – Y– – N

P2-03 060Ch

Marker Offset 2

Marker Offset 2

This parameter is used in conjunction with

parameters P2-02, P2-04, and P2-05 to determine

the orientation position offset from the marker

pulse. Refer to Orient Position Offset Selection on

page 25.

Note: Counts = Encoder PPR x 4.

0 to 65535 Cnts 0 No – – – Y– – N

P2-04 060Dh

Marker Offset 3

Marker Offset 3

This parameter is used in conjunction with

parameters P2-02, P2-03, and P2-05 to determine

the orientation position offset from the marker

pulse. Refer to Orient Position Offset Selection on

page 25.

Note: Counts = Encoder PPR x 4.

0 to 65535 Cnts 0 No – – – Y– – N

P2-05 060Eh

Marker Offset 4

Marker Offset 4

This parameter is used in conjunction with

parameters P2-02, P2-03, and P2-04 to determine

the orientation position offset from the marker

pulse. Refer to Orient Position Offset Selection on

page 25.

Note: Counts = Encoder PPR x 4.

0 to 65535 Cnts 0 No – – – Y– – N

No.

MEMOBUS/

Modbus

Address

Name

Digital Operator Display

Description Range

Default

Value

Change

During

Run

Control Method/

Access Level

Loading...

Loading...