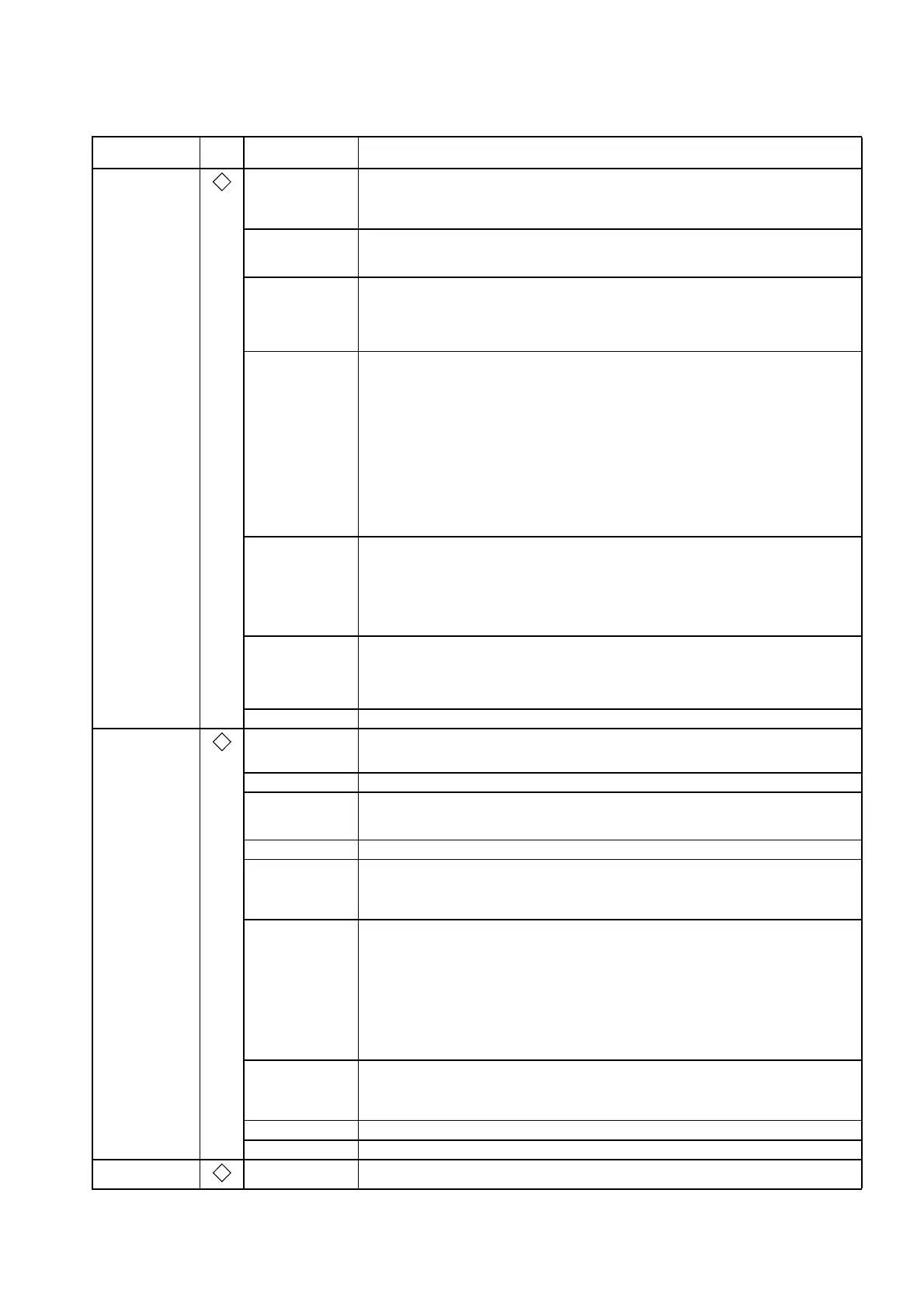

July 2005 Preface Addition:

Safety Precautions

Maintenance and Inspection

y

Precaution about using an Inverter with an elevator

y

Precaution about times when a holding brake is necessary

Chapter 2

Revision:

IMPORTANT

2 in Connection Diagram

Addition: y

IMPORTANT 13 in Connection Diagram

y

IMPORTANT in Standard Connection Diagrams

Chapter 5 Revision: Note *2 about E2-01

Addition: y

L8-32

y

36 and 3D settings of multi-function output terminal

y

Note *7 about C4-02 in the table in Factory Settings that Change with the Control

Method (A1-01)

Chapter 6

Revision: y

Fig.6.49 Baseblock Commands

y

Fig.6.63 PID Control Block

y

Examples of torque-limit operation in Torque Control

y

Application Precautions in Copying Constants

y

Fig.6.81 Brake ON/OFF Sequence Circuit Configuration

y

Confirming Startup Current and Reducing Carrier Frequency in Using Inverters for

Elevating Machines

Addition: y

Information on frequency detection 5 in Using Frequency Detection

y

Operation Selection After Cooling Fan Fault

y

Description about the changes in the OV and BTR levels that depend on the input

voltage in Setting the V/f Pattern

y

Description about frequency detection 5, which is an Inverter output signal to engage a

holding brake, in Using Inverters for Elevating Machines

Chapter 7

Addition: y

Fault and Alarm Detections

Descriptions of FAN

y

Probable causes and corrective actions for the OC, GF, OH (OH1), OL1, OL2, CPF04,

and CPF05 faults as well as the OH alarm

Descriptions about a short-circuit between, the +V, -V, and AC terminals.

y

Note in Table 7.3 Operation Error Displays and Incorrect Settings

Revision: Probable causes and corrective actions for the CPF23 fault

Chapter 8

Addition: y

Descriptions in Periodic Maintenance of Parts

y

Description of how to attach the fan cover for 200 V Class Inverters of 22 kW or 30

kW and 400 V Class Inverters of 22 kW to 55 kW

y

Description of how to replace the cooing fan and

circ

ulation fan for 400 V Class

Inverters of 185 kW, 220 kW, and 300 kW

Chapter 10 Addition: Note *4 in Fig.10.9

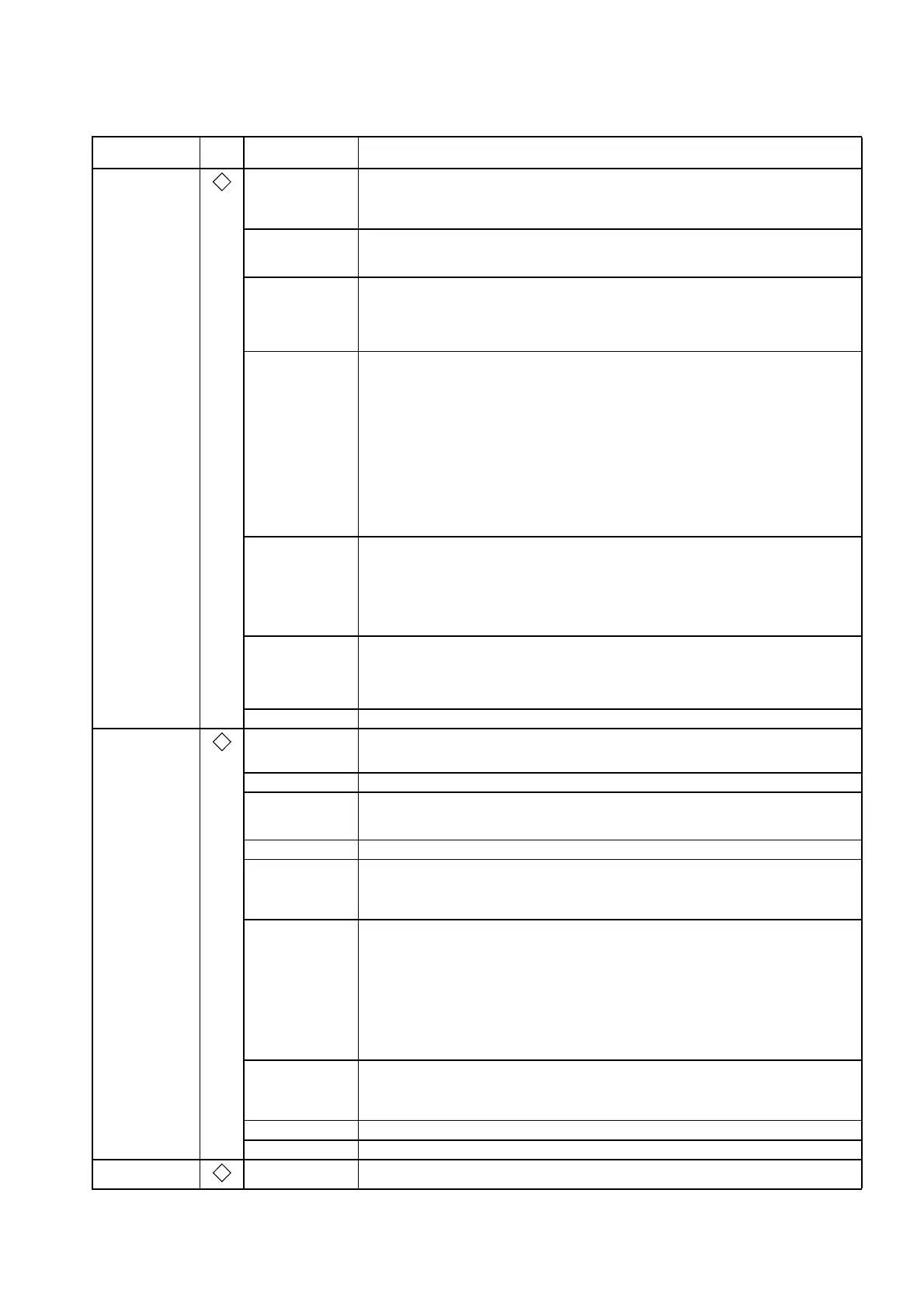

March 2006 Preface Addition: Safety Precautions

Trial Operation

Inverter settings precautions

Chapter 1 Revision: Table 1.9 Removing the Terminal Cover (Model CIMR-F7A20P4 Shown Above)

Chapter 2

Addition: y

Note in Table 2.4 Main Circuit Terminal Functions

y

IMPORTANT 14 and 15 in Connection Diagram

Revision: Description of installing a ground fault interrupter in Wiring the Main Circuits

Chapter 4 Revision: Description of stationary autotuning 2

Chapter 5

Addition: y

Following constants

H5-10, o2-09

y

Note in the table of L2 constants

Revision: Note *3 about E2-03 and E4-03

Chapter 6

Addition: y

Inputting Master Speed Frequency Reference Only (Current Input) in Frequency Refer-

ence

y

Following items in Continuing Operation

y

IMPORTANT in Speed Search

y

Additional description of master speed analog input in Continuing Operation at

Constant Speed When Frequency Reference Is Lost

Revision: y

Restarting Operation After Transient Fault (Auto Restart Function) in Continuing

Operation

y

Torque Control in Individual Operation

Example Diagrams of winding and rewinding operation during torque control

Chapter 7

Addition: y

Table 7.2 Causes and Corrective Actions for When the Digital Operator Goes Dark

y

The Inverter does not operate in Troubleshooting

Revision: Probable causes and corrective actions for the OC, GF, PUF, OV, UV1, UV2, UV3,

OH (OH1), OL1, OL2, and CPF03 to CPF05 faults and OH, PGO, and DEV alarms

Chapter 9 Addition: Notes *8 and *9 in Table 9.3

Chapter 10 Revision: Table 10.5 EMC Noise Filters

December 2007 Back cover Revision: Address

Date of

Publication

Rev.

No.

Section Revised Content

Loading...

Loading...