vii

Wiring

Selecting, Separating, and Laying External Cables

• Check the wiring to be sure it has been performed correctly.

There is a risk of motor run-away, injury, or an accident.

• Always use a power supply of the specified voltage.

There is a risk of burning.

• In places with poor power supply conditions, take all steps necessary to ensure that the input power

supply is within the specified voltage range.

There is a risk of device damage.

• Install breakers and other safety measure to provide protection against shorts in external wiring.

There is a risk of fire.

• Provide sufficient shielding when using the MP2000 Series Machine Controller in the following loca-

tions.

There is a risk of device damage.

Noise, such as from static electricity

Strong electromagnetic or magnetic fields

Radiation

Near to power lines

• When connecting the battery, connect the polarity correctly.

There is a risk of battery damage or explosion.

• Only qualified safety-trained personnel should replace the battery.

If the battery is replaced incorrectly, machine malfunction or damage, electric shock, or injury may result.

• When replacing the battery, do not touch the electrodes.

Static electricity may damage the electrodes.

• After replacing the battery, separate the used battery from regular waste and deal with it according to

the applicable local regulations.

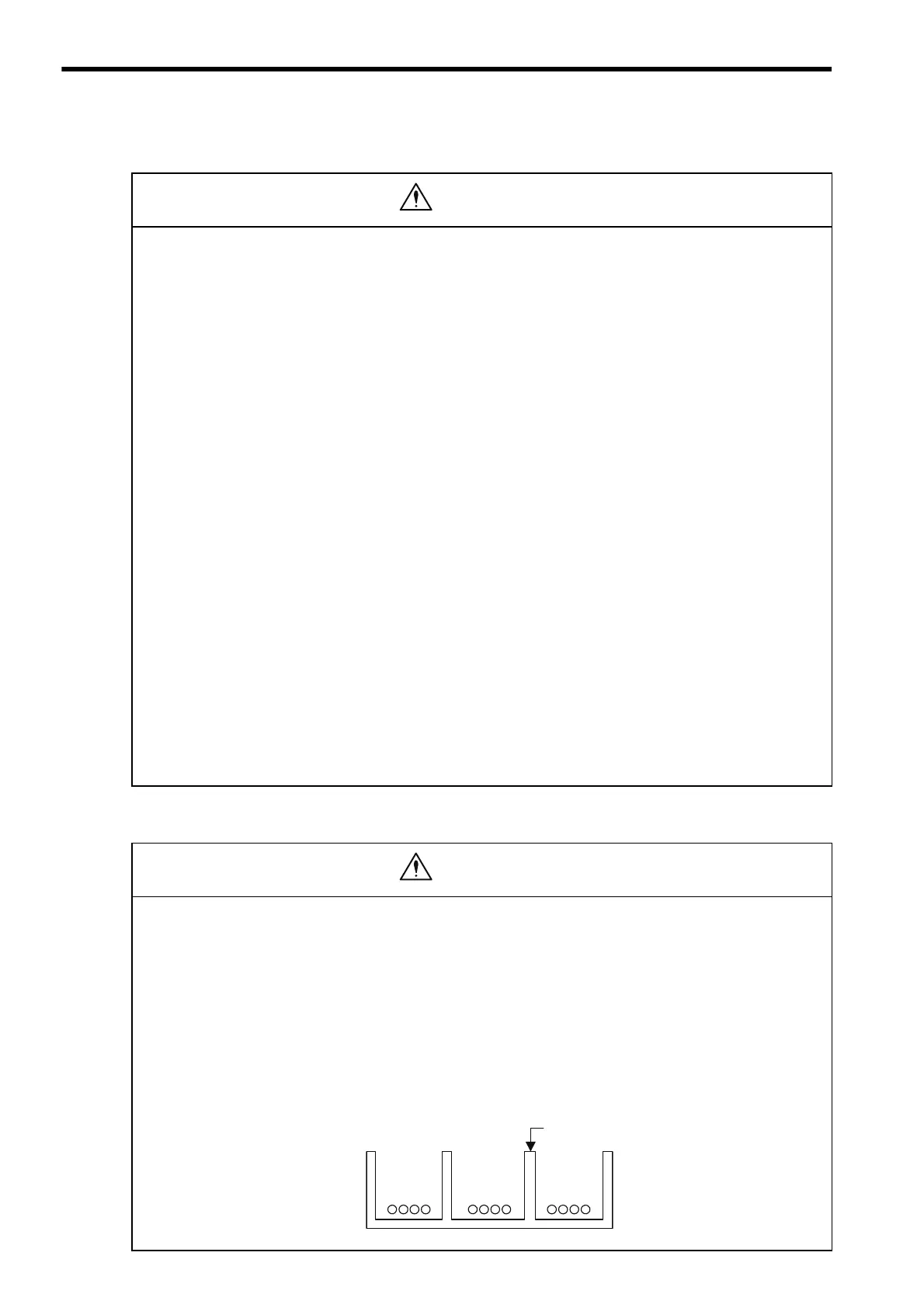

• Consider the following points when selecting the I/O signal lines (external cables) to connect the

MP2000 Series Machine Controller to external devices.

Mechanical strength

Noise interference

Wiring distance

Signal voltage, etc.

• It is possible to reduce the influence of noise from the power lines. For that purpose, separate the I/O

signal lines from the power lines both inside and outside the control box.

If the I/O signal lines and power lines are not separated properly, malfunctioning may result.

Example of Separated External Cables

Steel separator

Power

circuit

cables

General

control cir-

cuit cables

Digital I/O

signal

cables

Loading...

Loading...