YL9112 Isocratic Pump

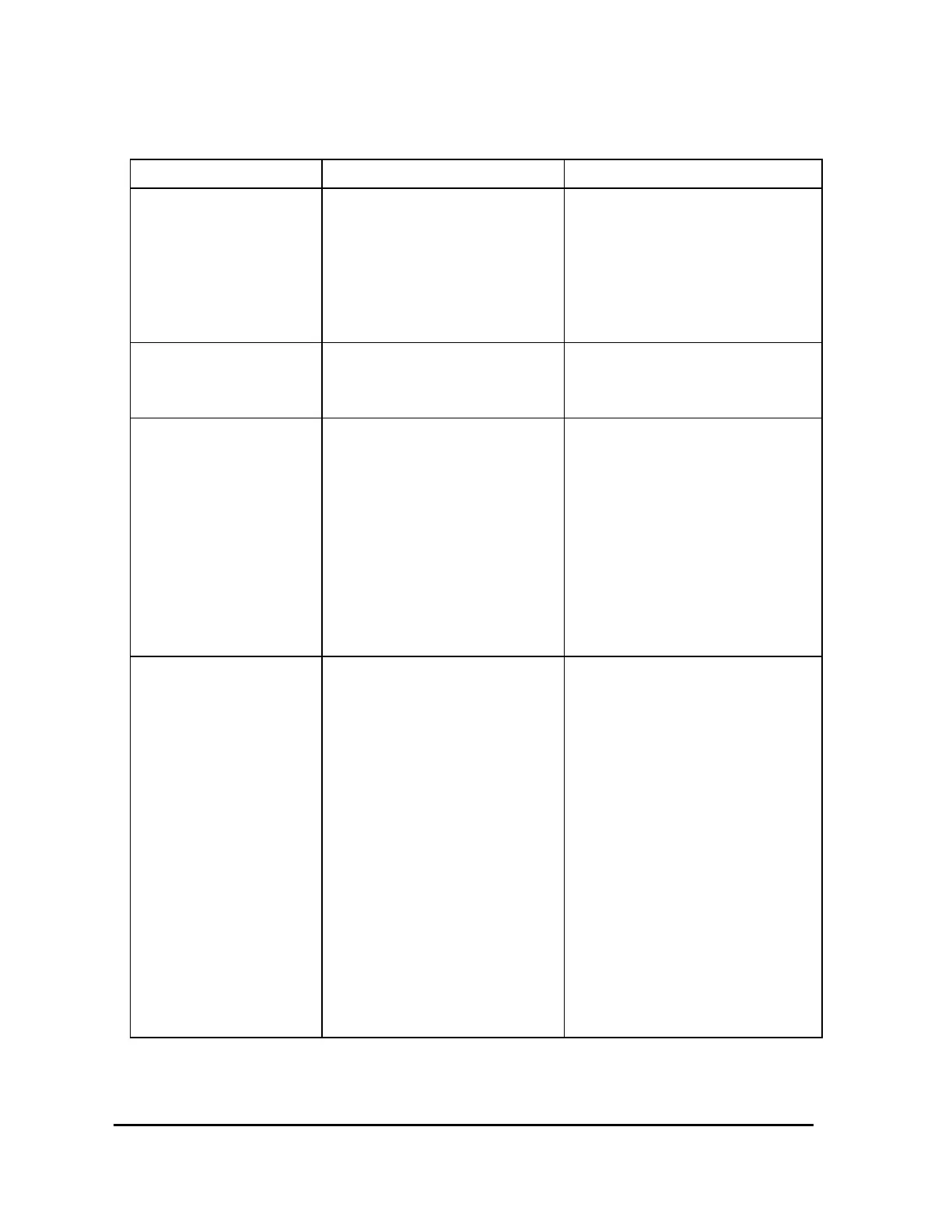

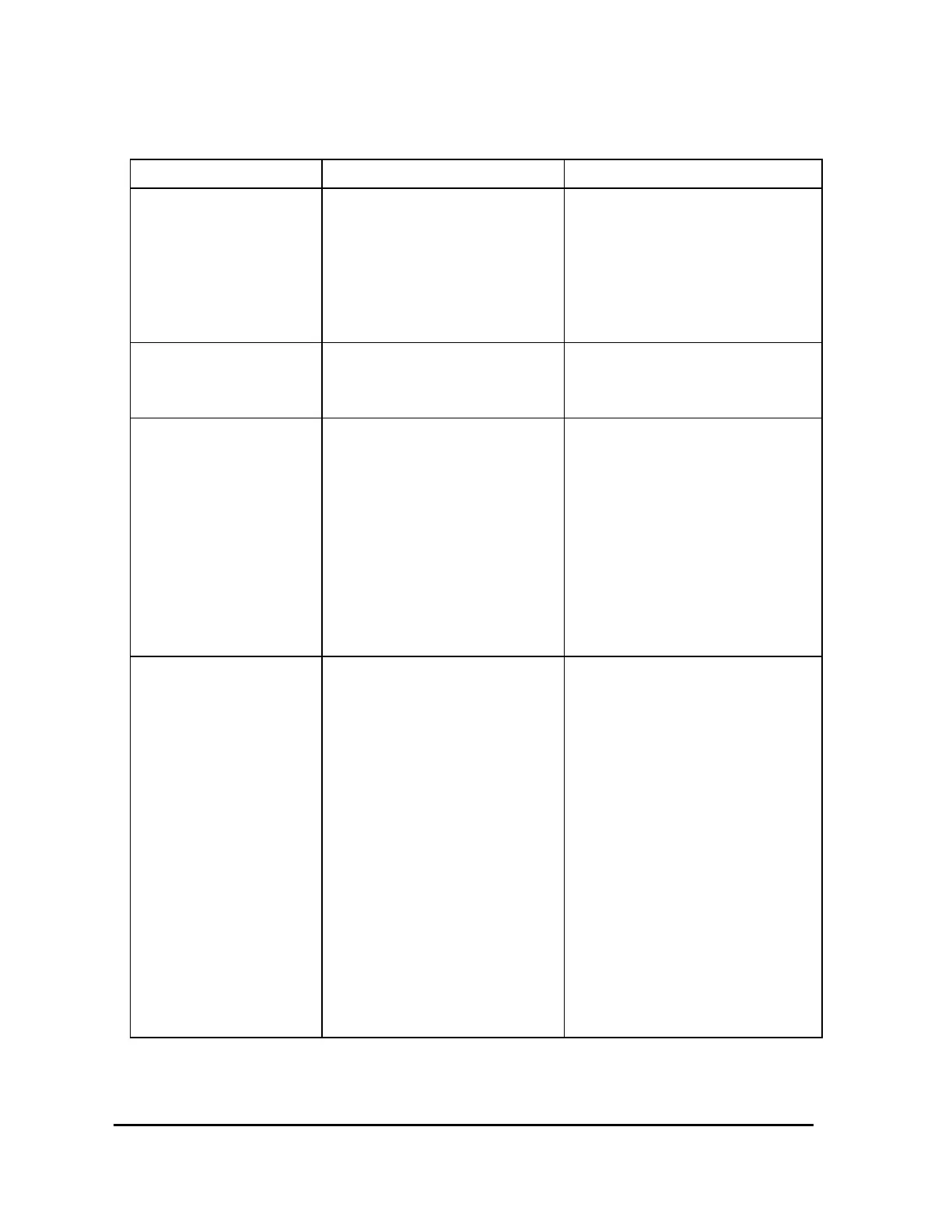

Problem Cause How to fix

Pressure upper

limit is loaded.

-Tubing inside is blocked.

-Check valve is blocked.

-Solvent is changed.

-Replace blocked tubing by

loosening to be from tail side

in turn.

-Replace outlet check valve.

-Wait until solvent is completely

changed.

Pressure

increases or

decreases.

-Change of solvent is

incomplete.

-Wait until change is completely

performed.

-Wait until pressure is stable.

Solvent is not

flowed out

-Air bubble is in pump head.

-Air separation status of

solvent is bad.

-Check valve is not good.

-Liquid containing oil flows

into head part.

-Perform prime/purge again.

-Take measures so that air

separation condition of solvent

may be good, and perform

prime/purge again.

-Wash or replace check valve.

-Remove oil in head sufficiently

with strong organic solvent

using prime/purge port.

Pressure is

unstable.

-Check valve is bad or

defected.

-Air separation or mixing

conditions of solvent is

bad.

-Compression compensating

reference

value of configuration

mode is wrong.

-Cam shaft is loosened.

-High pressure seal was

worn.

-Pump head was loosened.

-Wash or replace check valve.

-Use mobile phase with well mixed

solvent, and improve air separation

condition.

-Initialize compensation value or

re-input proper value.

-Tighten wrench bolt of cam shaft

-Replace high pressure seal.

-Tighten nut of pump head.

30

Loading...

Loading...