YL9110 Quaternary Pump

5-10. Troubleshooting

In case general problem occurs as the following table, confirm the possible causes regarding this first,

and then take proper countermeasures. The following table is countermeasure in case general problems

occur.

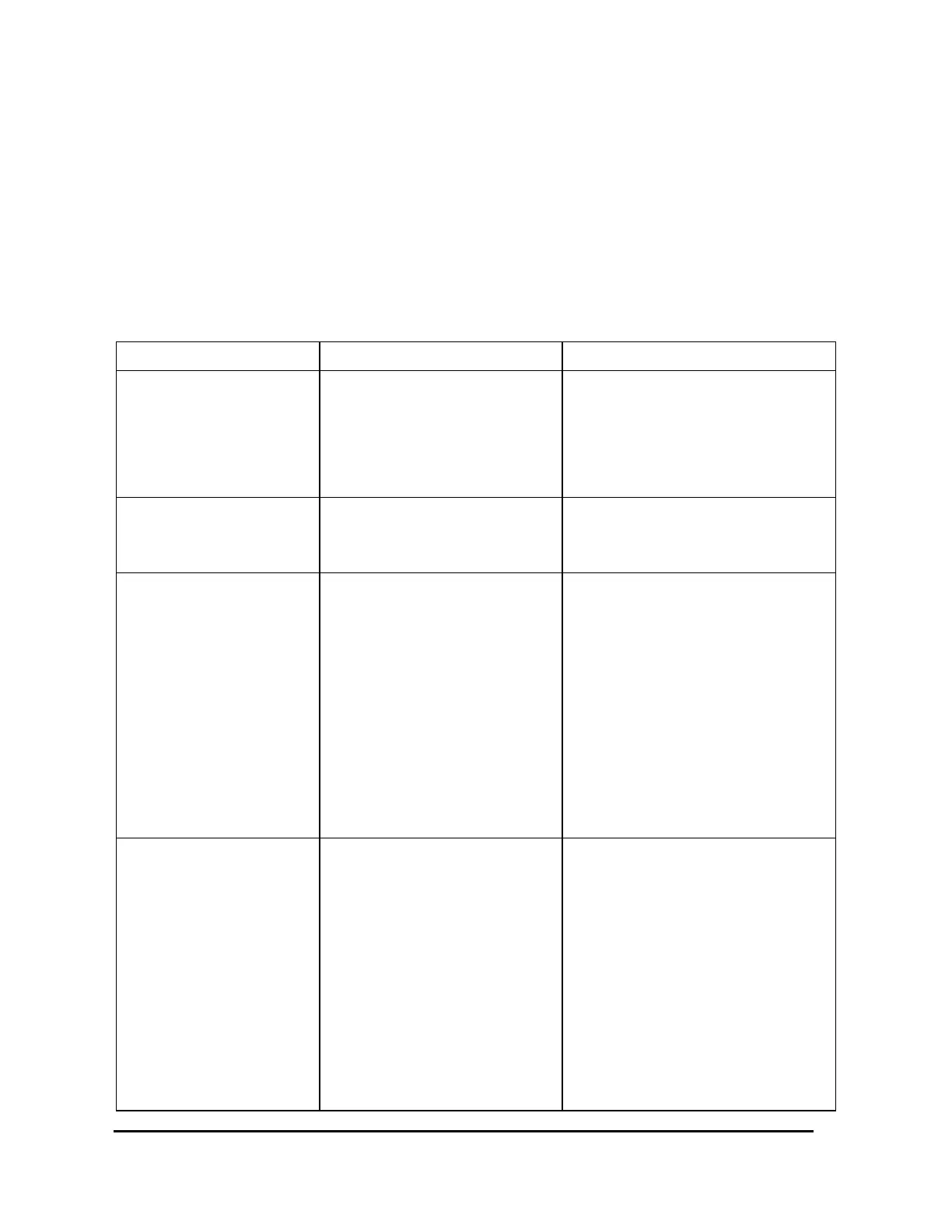

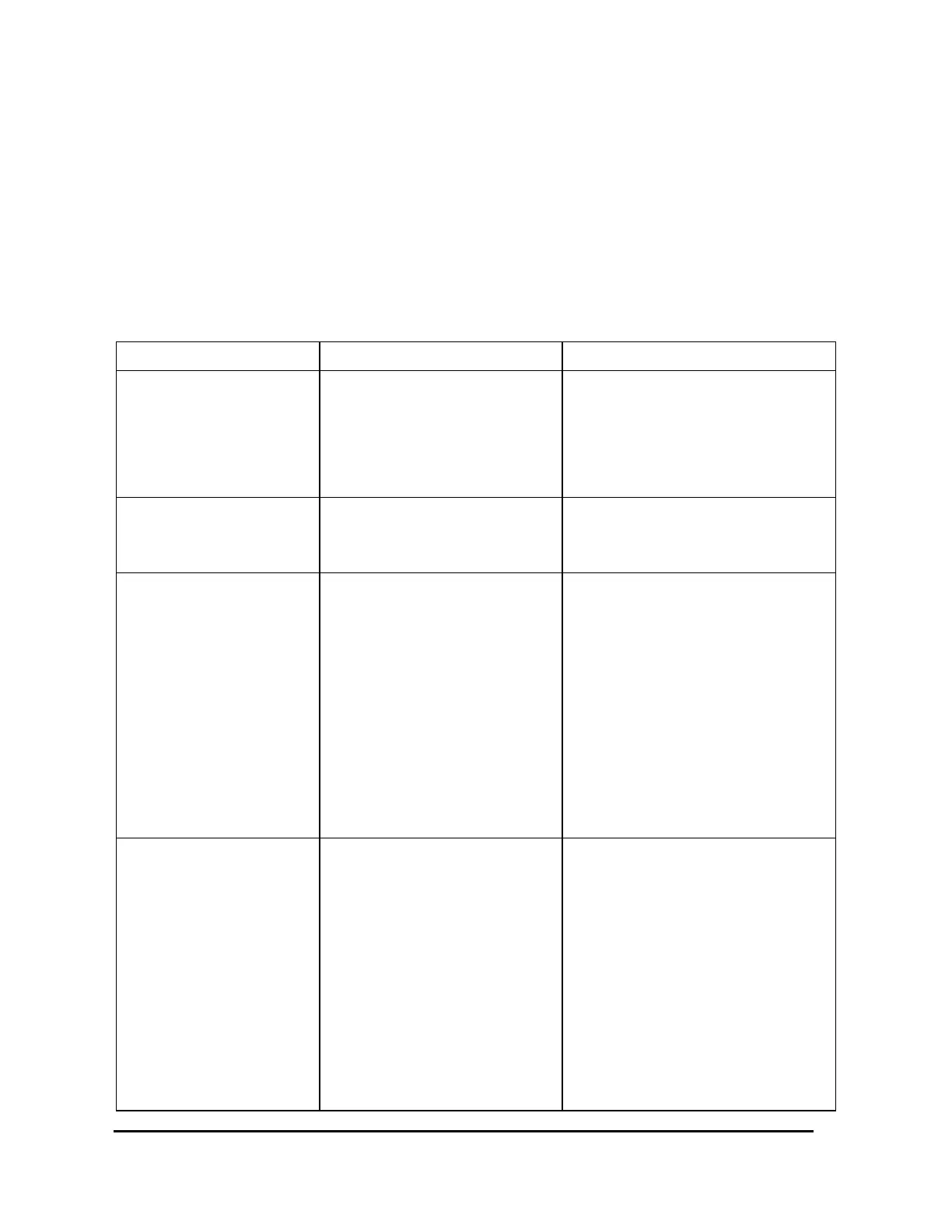

Problem Cause How to fix

Pressure upper

limit is loaded.

-Tubing inside is blocked.

-Check valve is blocked.

-Solvent is chan

ed.

-Replace blocked tubing by

loosening to be from tail side in turn.

-Replace outlet check valve.

-Wait until solvent is completely

chan

ed.

Pressure

increases or

decreases.

-Change of solvent is incomplete.

-Column is unstable.

-Wait until change is completely

performed.

-Wait until pressure is stable.

Solvent is not

flowed out

-Air bubble is in pump head.

-Air separation status of

solvent is bad.

-Check valve is not good.

-Liquid containing oil flows

into head part.

-High pressure seal was worn.

-Perform prime/purge again.

-Take measures so that air

separation condition of solvent may

be good, and perform prime/purge

again.

-Wash or replace check valve.

-Remove oil in head sufficiently

with strong organic solvent

using prime/purge port.

-Replace the high pressure seal.

Pressure is

unstable.

-Check valve is bad or defected.

-Air separation or mixing

conditions of solvent is bad.

-Compression compensating

reference value of configuration

mode is wrong.

-Cam shaft is loosened.

-High pressure seal was worn.

-Pump head was loosened.

-Wash or replace check valve.

-Use mobile phase with well mixed

solvent, and improve air separation

condition.

-Initialize compensation value or

re-input proper value.

-Tighten wrench bolt of cam shaft

-Replace high pressure seal.

-Tighten nut of pump head.

30

Loading...

Loading...