YL9110 Quaternary Pump

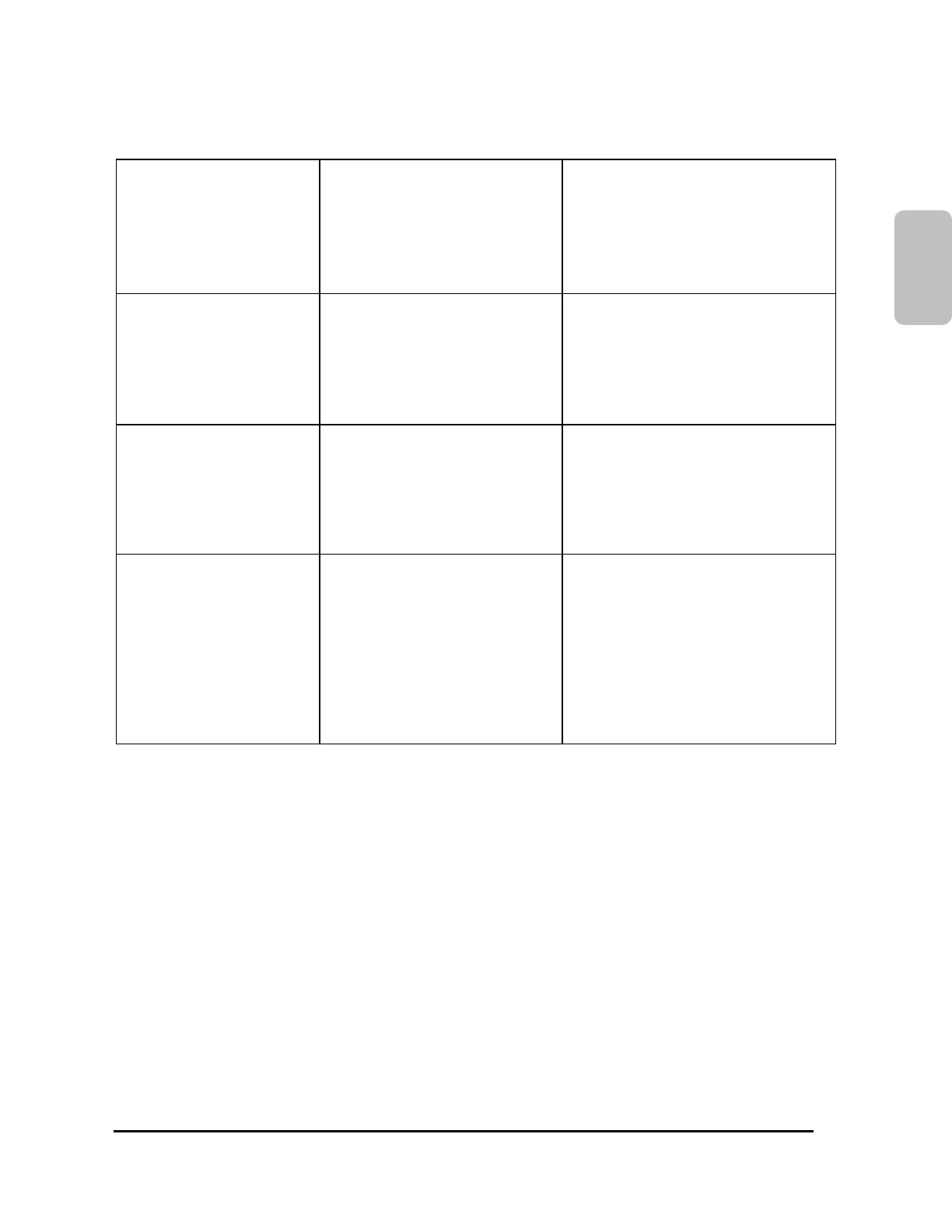

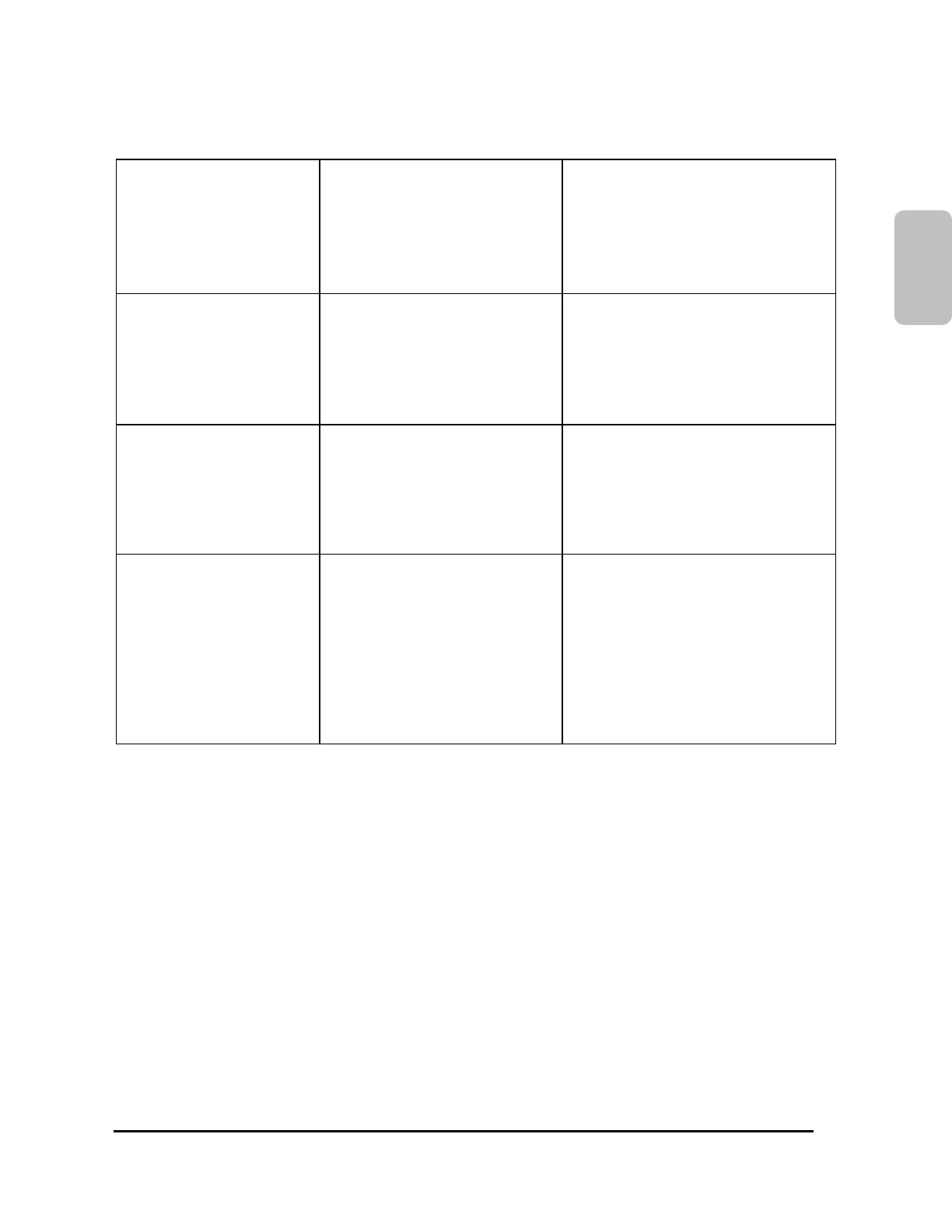

Liquid is leaked

or pressure

reduces when

cleaning port is

not used

-High pressure seal was worn.

-Plunger was worn.

-Replace high pressure seal.

-Replace plunger.

Liquid is leaked

from inside of

instrument.

-Fitting in instrument was

loosened.

-Damper was damaged.

-Low pressure seal was worn.

-Tighten fitting in instrument.

-Replace.

-Replace low pressure seal.

Pump is not

operated after

input of power.

-Power voltage is unstable or low.

-Strong induction voltage is

generated in the surroundings.

-Use stable, proper DC power source.

-Close induction power source in

surroundings, or install instrument

away from power source.

Noise is too

high

-Load is caused to piston carrier.

-Timing belt is loose.

-Motor is in defect.

-Supply lubricant in carrier body.

-Reduce clearance above belt by

adjusting guide location of timing

belt.

-Inspect connection status of motor

cable, and replace motor if noise

is severe only in high pressure.

L9110

31

Loading...

Loading...