<3.Installation>

19

IM01C25A01-01E

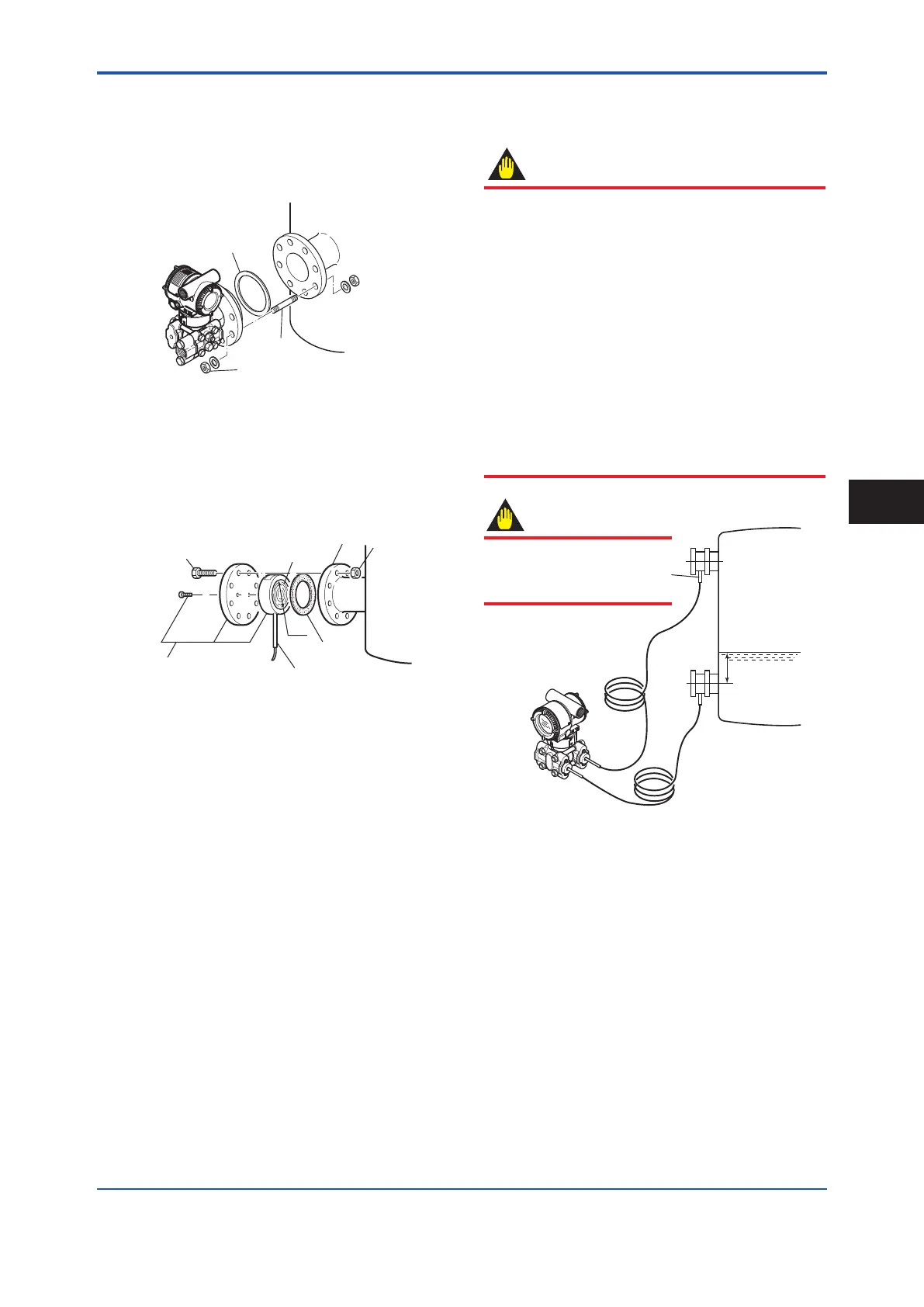

3.2.1 EJ210

Thetransmitterismountedonaprocessusingits

highpressuresideangeasshowninFigure3.5.The

customershouldpreparethematingange,gasket,stud

boltsandnuts.

F0305.ai

Gasket

Stud bolt

Nut

Figure3.5 EJ210Mounting

3.2.2 EJ118andEJ438

Mountthediaphragmsealsusingtheangesasshownin

Figure3.6.Thematingange,gasket,boltsandnutsare

tobeprocuredbythecustomer.

Nut

Flange

Diaphragm

ød

Gasket

F0306.ai

Bolt

The product is

shipped with these

parts assembled.

Correctly install the diaphragm

seals on the high and low pressure

sides of the process (The label on

each diaphragm seal is marked

HIGH or LOW).

Figure3.6 MountingtheDiaphragmSeals

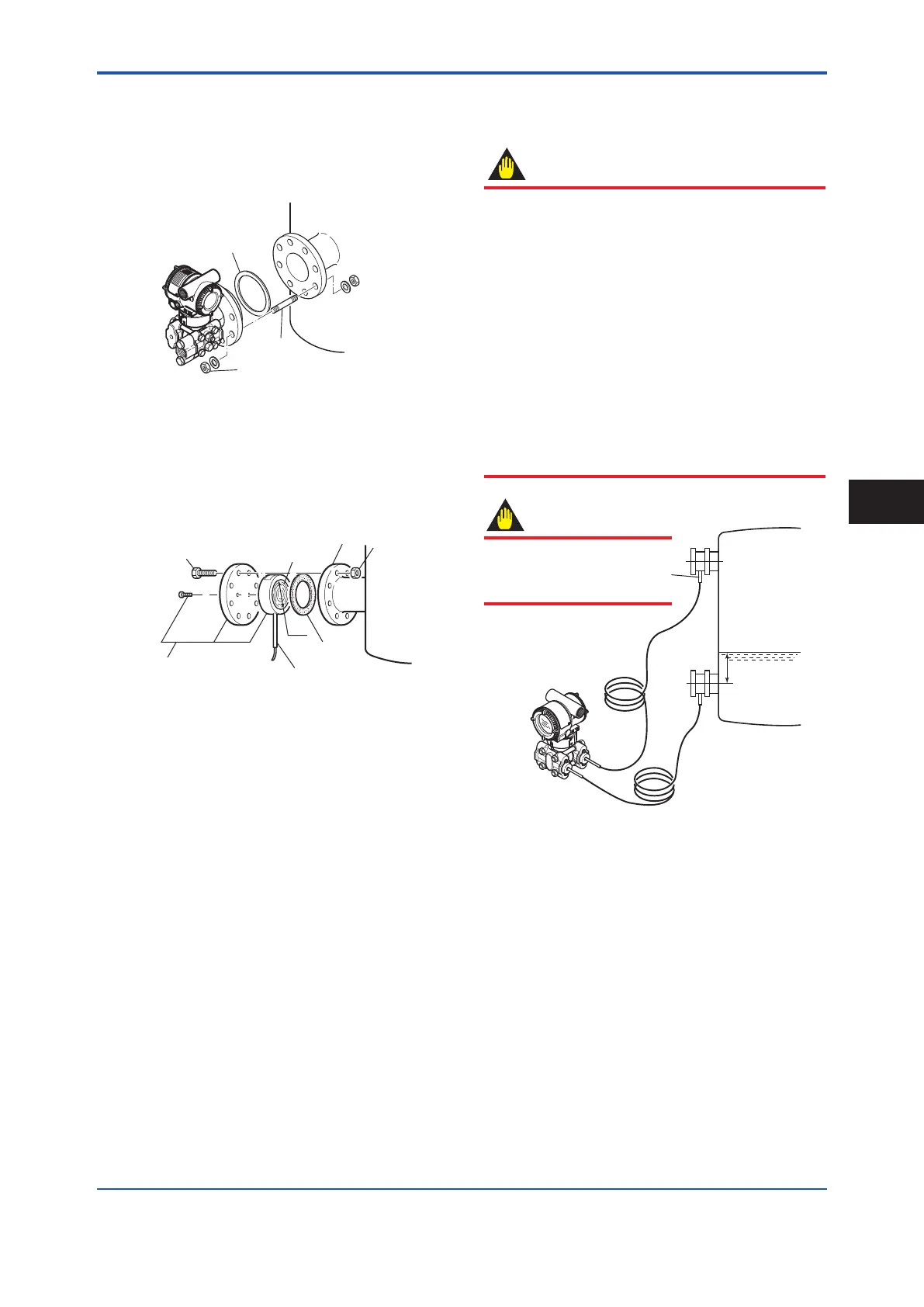

3.3 DiaphragmSealsInstallation

Consideration

IMPORTANT

• Whenmeasuringtheliquidlevelofthetank,the

minimumliquidlevel(zeropoint)mustbesettoa

levelatleast50mmabovethecenterofthehigh

pressuresidediaphragmseal(seeFigure3.7).

• Correctlyinstallthediaphragmsealsonthehigh

andlowpressuresidesoftheprocess,checking

thelabeloneachseal.

• Toavoidmeasuringerrorduetstemperature

differencebetweenthetwodiaphragmseals,

capillarytubemustbeboundtogether.The

capillarytubemustbesecurelyxedtothetank

walltopreventmovementbywindorvibration.

Ifthecapillarytubeistoolong,looselycoilthe

extratubeportion(coildiameterof300mmor

more)andsecurethecoiledtubewithaclamp.

F0307.ai

50 mm minimum

Minimum

liquid level

High

pressure

side

Low

pressure

side

The transmitter should

be installed as low as

possible below the

position where the high

pressure side

diaphragm seal is

installed.

Install the sealed diaphragm

so that the shank positions

downward.

IMPORTANT

Figure3.7 InstallingtheDiaphragmSealstoa

Tank

Installation

3

Loading...

Loading...