<3.Installation>

21

IM01C25A01-01E

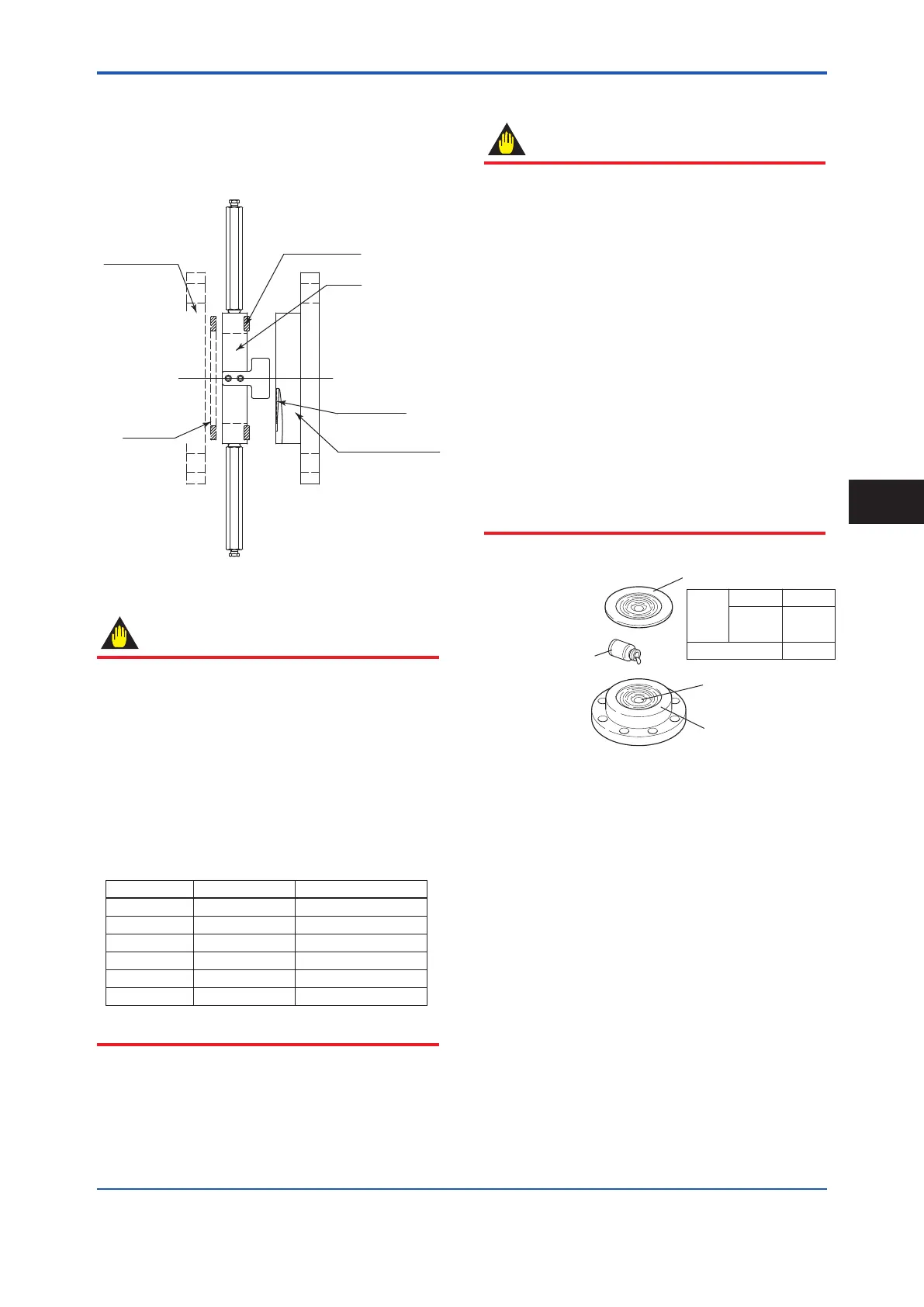

3.4.2 MountingtoProcessFlange

Tightentheboltstocompletelyclosethegapbetweenthe

ringandthepressuredetectorsection.

Thematingange,gasket,studboltsandnutsareto

procuredbythecustomer.

F0310.ai

Ring

Diaphragm

Pressure-detector

section

Gasket

Mating flange

Spiral gasket

Figure3.10 MountingtoProcessFlange

IMPORTANT

• Conrmthatthereisnogapbetweenthering

andtheprocess-detectorsectionaftertheyare

mountedontheprocessange.Agapcanleadto

asudden,explosivereleaseofprocessuids.

• Whenmountingorremovingthering,takecarenot

totiltthepressuredetectordownwardasthering

canslipoffandcauseinjury.

• Whenre-mountingthering,usethenewspiral

gasketasshowninbelowtable.

Table3.1 SpiralGasketforPressureDetector

SectionSide*

Partnumber Size Description

F9350SV ø100×ø120×t4.5 For3-inchange

F9970XF ø100×ø120×t4.5 For3-inchange**

F9350ST ø70×ø90×t4.5 For2-inchange

F9970XD ø70×ø90×t4.5 For2-inchange**

F9346ZH ø60×ø75×t4.5 For11/2-inchange

F9970XB ø60×ø75×t4.5 For11/2-inchange**

*: Material;316SST(Hoop),PTFETeon(Filler)

**: Foroil-prohibiteduse(Optioncode:/K1,/K2,/K5,/K6)

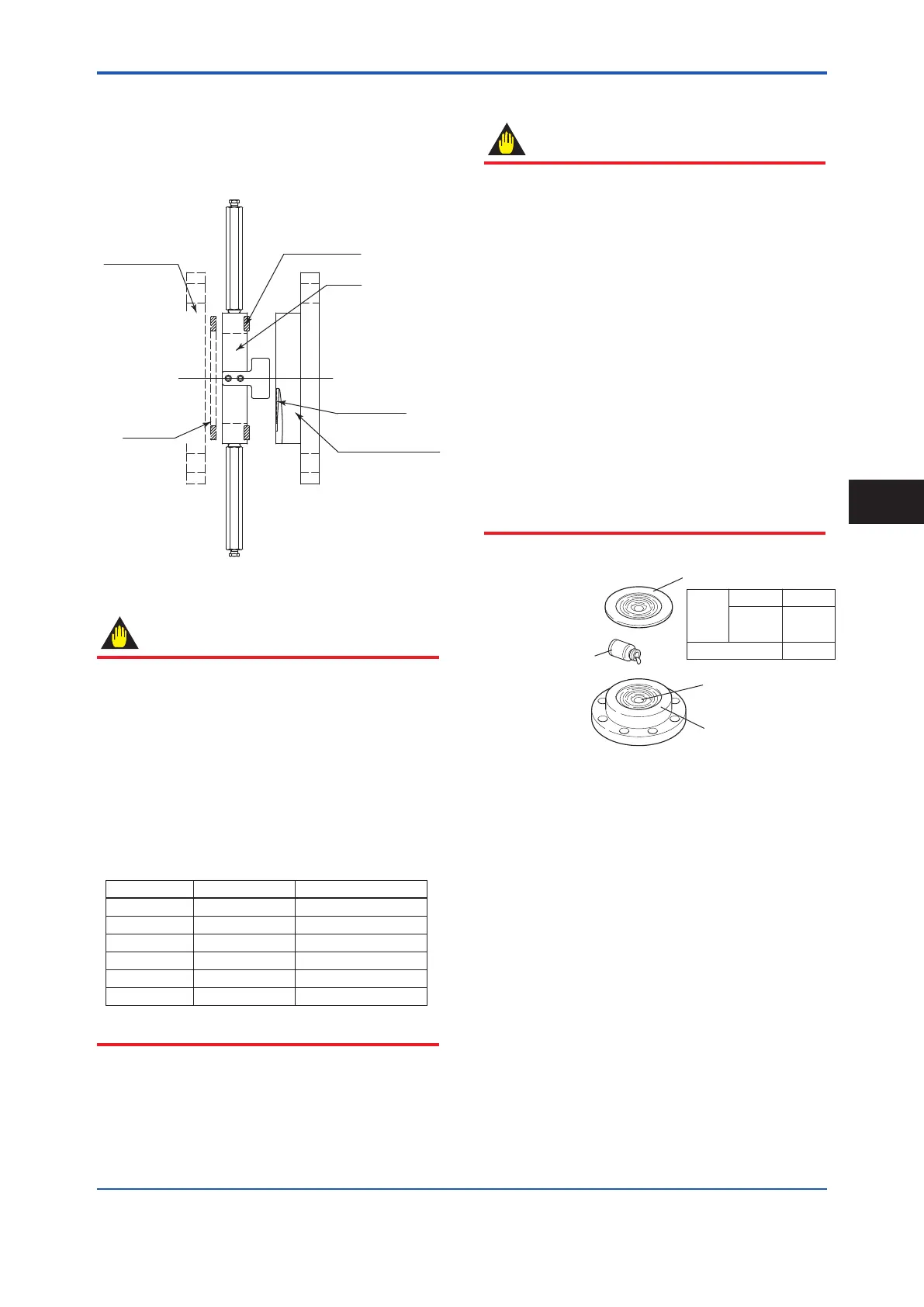

3.5 AfxingtheTeonFilm

IMPORTANT

TheFEPTeflonoptionincludesateflonfilmand

fluorinatedoil.Beforemountingthetransmittertothe

processange,afxtheteonlmasfollows:

1)Positionthediaphragmsealsothatthediaphragm

isinanupwardposition.

2)Pourtheuorinatedoilonthediaphragmand

gasketareacoveringitcompletelyandevenly.Be

carefulnottoscratchthediaphragmorchangethe

itsshape.

3)Afxtheteonlmoverthediaphragmandgasket

area.

4)Next,carefullyinspectthecoverandtrytoidentify

anyentrappedairbetweenthediaphragmand

theteonlm.Theairmustberemovedtoensure

optimumperformance.Ifairpocketsarepresent,

useyourngerstoremovetheairbystartingatthe

centerofthediaphragmandworkyourwayout.

5)PositionthegasketontheTeonlm.

6)Mountthetransmitterontotheprocessange.

F0311.ai

EJ210 F9347YD

EJ118

EJ438

F9347YA

2B

(50A)

F9347XA3B(80A)

Teflon film

PART No.

Diaphragm

Fluorinated oil

[PART No. : F9145YN]

Gasket area

Figure3.11 AfxingtheTeonFilm

Installation

3

Loading...

Loading...