IM 05P02D41-11EN page 10/14

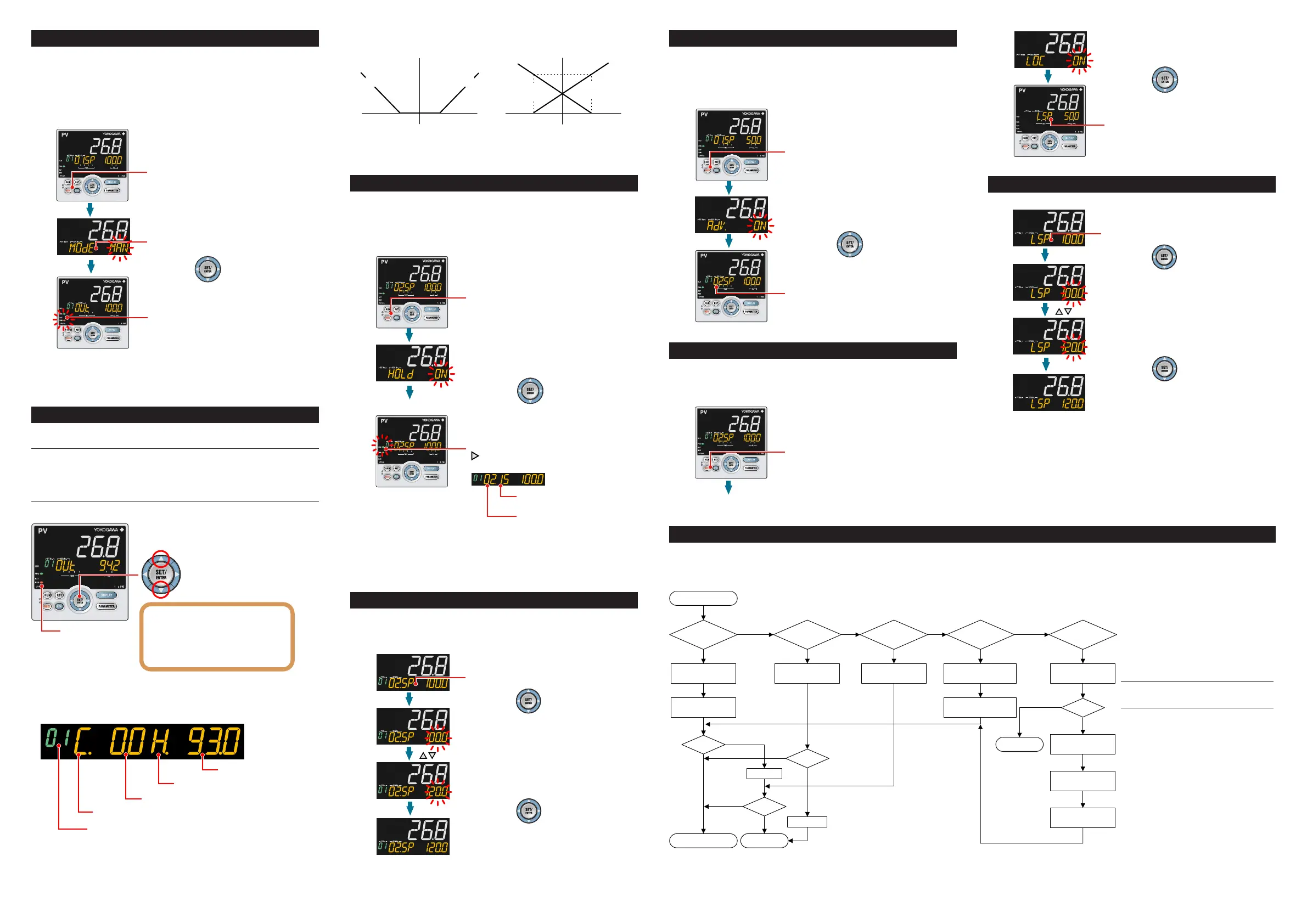

5. Switching between AUTO and MAN

AUTOandMANswitching canbeperformedusing anyofthefollowing: (1)MODE

key,(2)Contactinput,(3)Contactinput,and(4)Communication.

ThefollowingshowsanexampleofswitchingusingtheMODEkey.

WhenAUTOandMANswitchingfunctionis assignedtothe contactinput,andthe

contactinputisON,theswitchingbykeyoperationcannotbeperformed.

Fordetails,seeUser’sManual.

Displays ”MODE MAN” in AUTO mode.

Displays ”MODE AUTO” in MAN mode.

Press MODE key several times.

Show the Operation Display.

4.

MAN lamp is lit in MAN mode.

Press the SET/ENTER key.

WhenAUTOisswitchedintoMAN,thecontroloutputvalueinAUTOmodeisheld.

Thecontrollercanbeoperatedmanuallyfromtheholdvalue.

Ifthemanualpresetoutputisset (MPONparameter≠ OFF),thecontrollercanbe

operatedmanuallyfromthearbitraryoutputvalue(MPO1toMPO5parameters).

6.

Manipulating Control Output in Manual Mode

NOTE

Inmanualmode,control outputismanipulatedbyoperatingthekeys(thevalueis

changedusingtheUp/Downarrowkeys,thenoutputtedasitis).

Evenifthe SET/ENTERkeyisnotpressed,thecontroloutputvaluechangesac-

cordingtothedisplayedvalue.

Instopmode(whentheRSTlampislit),controloutputcannotbemanipulated.

MAN lamp is lit.

Up arrow key: increases control output.

Down arrow key: decreases control output.

In Position proportional control:

Up arrow key; opens the valve.

Down arrow key; closes the valve.

Output; only while pressing a key.

OUT; valve opening (0-100%)

Output manipulation in Position proportional control

is not restricted from output limiters (OH, OL).

Manual operation in Heating/cooling control

Symbol of cooling side

Program pattern (PTNO.) number

Symbol of heating side

Heating-side control output

Cooling-side control output

Uparrowkey: concurrentlydecreasescooling-sidecontroloutputandincreases

heating-sidecontroloutput.

Downarrowkey:concurrentlyincreasescooling-sidecontroloutputanddecreases

heating-sidecontroloutput.

(Eithernoneofthe heating-sideandcooling-sideoutputs arepresented,orboth of

themarepresentedaccordingtothedeadbandsetting.)

DB=24.8

Dead band: Operation parameter DB

Control computation output Control computation output

12.40-12.4

Manipulated output change

when a dead band is positive (+)

Actual output (%)

100

DB= -24.8

12.40-12.4

Manipulated output change

when a dead band is negative (-)

100

Cooling-side

manipulated output

Heating-side

Heating-side

manipulated output

Cooling-side

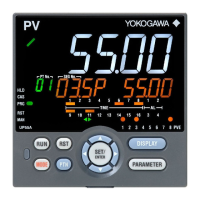

7.

Enabling/Disabling Hold Mode of Program Operation

Enabling/disablingholdmodeofprogramoperationcan beperformedduringpro-

gramoperationusinganyofthefollowing:(1)MODEkey,(2)Parameter,(3)Contact

input,and(4)Communication.

ThefollowingshowsanexampleofswitchingusingtheMODEkey.

Show the Operation Display.

Press the MODE key.

The number of segments included

in the selected program pattern.

The segment number for which

operation is in progress.

The figure below is displayed while the right

arrow key hold down.

Displays ”HOLD ON” in PROG mode.

Displays ”HOLD OFF” in HOLD mode.

HLD lamp is lit in HOLD mode.

Press the SET/ENTER key.

The parameter HOLD (Pause/cancel release

of program operation) is displayed (during

program operation.)

1.

2.

3.

4.

Show the Operation Display.

Press the MODE key.

The number of segments included

in the selected program pattern.

The segment number for which

operation is in progress.

The figure below is displayed while the right

arrow key hold down.

Displays ”HOLD ON” in PROG mode.

Displays ”HOLD OFF” in HOLD mode.

HLD lamp is lit in HOLD mode.

Press the SET/ENTER key.

The parameter HOLD (Pause/cancel release

of program operation) is displayed (during

program operation.)

Otheroperatingproceduresfordisablingtheholdmode:

(1)PresstheRUNkeyfor1 secondduringhold-mode operation.Inthis case,the

controllerresumesprogramoperation.

(2)Executethe“Advance“functionduringhold-modeoperation.Inthiscase,the

segmentisadvanced.

8.

Changing Program Setpoints when in Hold Mode

Thefollowingoperating procedureschangesaprogramsetpointofsoaksegment

duringHold-modeoperation.

Theprogramoperation isstartedwhen releasingtheHoldafterchanging thepro-

gramsetpoint.

.

Set program operation in hold mode.

.

.

Blinks during the change.

Blinks during the change.

Press the SET/ENTER key.

Press the SET/ENTER key.

Press the Up/Down arrow keys to display the required setpoint.

9.

Executing “Advance” Function

“Advance”canbeperformedduringprogramoperationusinganyofthefollowing:(1)

MODEkey,(2)Parameter,(3)Contactinput,and(4)Communication.

ThefollowingshowsanexampleofswitchingusingtheMODEkey.

Whenexecutingthe“Advance”functionduringhold-modeoperation,theholdmodeisdisabled.

4.

The segment is advanced.

Press the SET/ENTER key.

Show the Operation Display.

Press the MODE key.

The ADV (Advance of segment) is displayed (during

program operation.)

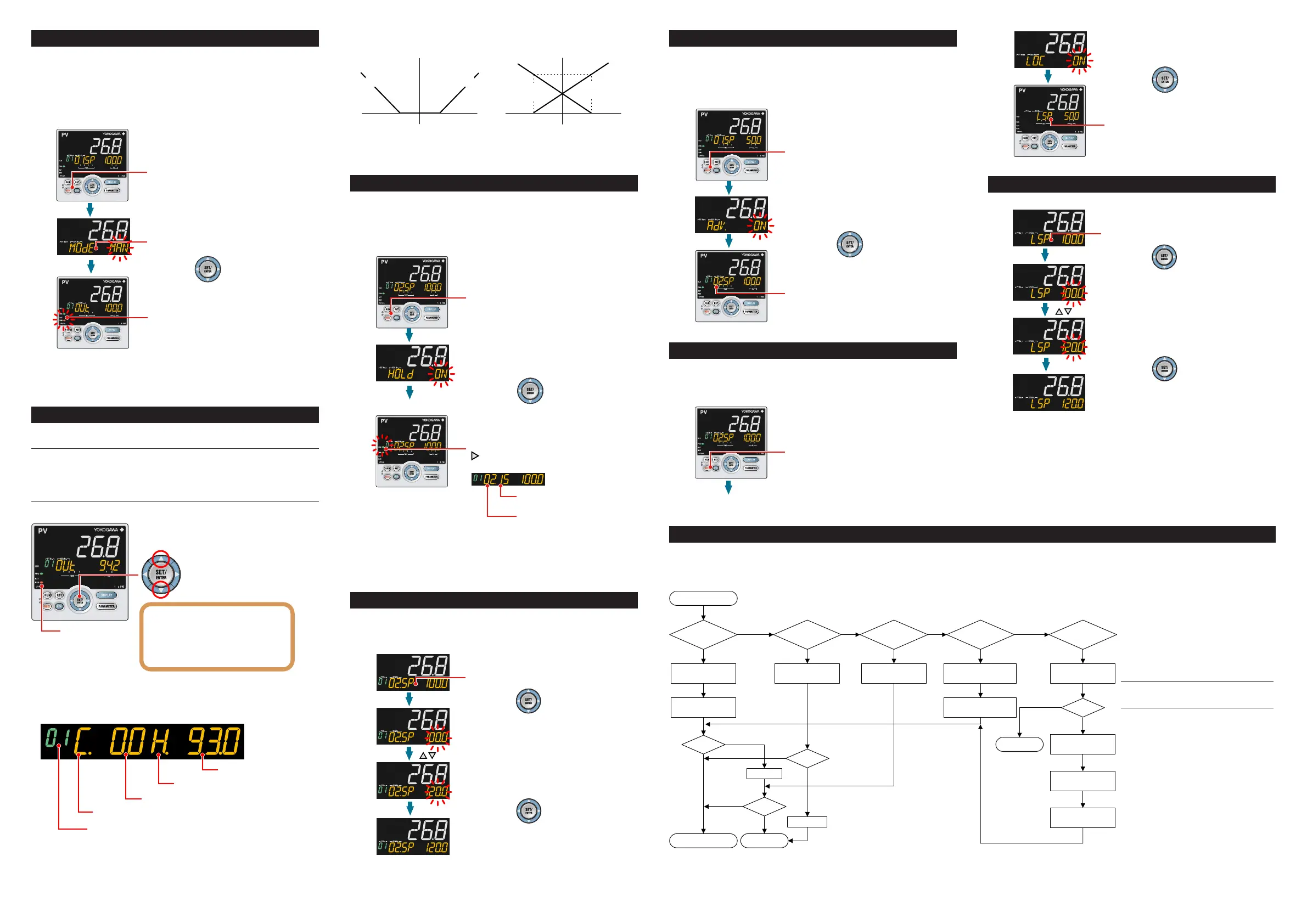

10.

Switching to Local-mode (LOCAL) Operation

Switchingtolocal-modecanbeperformedusinganyofthefollowing:

(1)MODEkey(userfunctionkey),(2)Parameter,(3)Contactinput,and(4)Communication.

ThefollowingshowsanexampleofswitchingusingtheMODEkey.

1.

2.

3.

4.

“LSP” is displayed when

in local-mode operation.

Press the SET/ENTER key.

Show the Operation Display.

Press the MODE key several times.

The LOC (local operation) is displayed.

■

Remedies if Power Failure Occurs

during Operations

• Instantaneouspowerfailurewithin20ms.

Apowerfailureis notdetected.Normal

operation continues.

• Powerfailureforlessthanabout5seconds,

orforabout5secondsormore.

Affectsthe"settings"and"operationsta-

tus."

Fordetails,seeUser'sManual.

NOTE

Writedownthesettings ofparametersfor a

repairrequest.

■FortheErrorsatPowerOn

and the Errors during Op-

eration, see “Parameters”

in this manual.

.

“LSP” is displayed when

in local-mode operation.

Press the SET/ENTER key.

Show the Operation Display.

Press the MODE key several times.

The LOC (local operation) is displayed.

11.

Changing Setpoints during Local-mode Operation

Thefollowingoperatingprocedureschangessetpointsduringlocal-modeoperation.

.

.

.

“LSP” is displayed when in local-mode operation.

Press the SET/ENTER key.

Press the SET/ENTER key.

Blinks during the change.

Blinks during the change.

Press the Up/Down arrow keys to display the required setpoint.

■TroubleshootingFlow

IftheOperationDisplaydoesnotappearafterturningonthecontroller’spower,checktheproceduresinthefollowingowchart.

Ifaproblemappearstobecomplicated,contactoursalesrepresentatives.

defective?

Contact us for repair.

Problem solved.

No communication

capability

Completely

inactive?

Yes

Yes

Yes

No

No

No

Key

operation

failure?

Yes

No

Yes

Check wiring of the

power terminals.

Check the key lock

setting.

Display

failure?

*

Yes

No

Turn off power, and

then turn it on again.

I/O signal

failure?

Yes

No

Check the

supply voltage.

Check the

specifications and polarity

of connected devices .

Check the communication-

related parameters.

Check the specifications

of communication

devices.

Check the

communication wiring.

Communication

failure?

No

With

communi-

cation?

Yes

Yes

Normal?

Is the

key locked?

Check the specifications

of the controller.

Yes

No

Correct?

Correct the error(s).

Cancel the setting.

Check the I/O specifications

of the controller.

* The LCD (a liquid crystal display) is used for

a display portion of this product.

The LCD has a characteristic that the display action

becomes late at the low temperature.

Additionally, the luminance and contrast degradation

are caused due to aged deterioration.

However, the control function is not affected.

12. Troubleshooting

Loading...

Loading...