JOHNSON CONTROLS

74

FORM 102.20-N1

ISSUE DATE: 7/06/2016

SECTION 3 - HANDLING, STORAGE, AND INSTALLATION

COIL PIPING

Do not test, clean and ush piping through

this equipment.

Isolate this equipment from pressure test-

ing of water, steam gas and air piping.

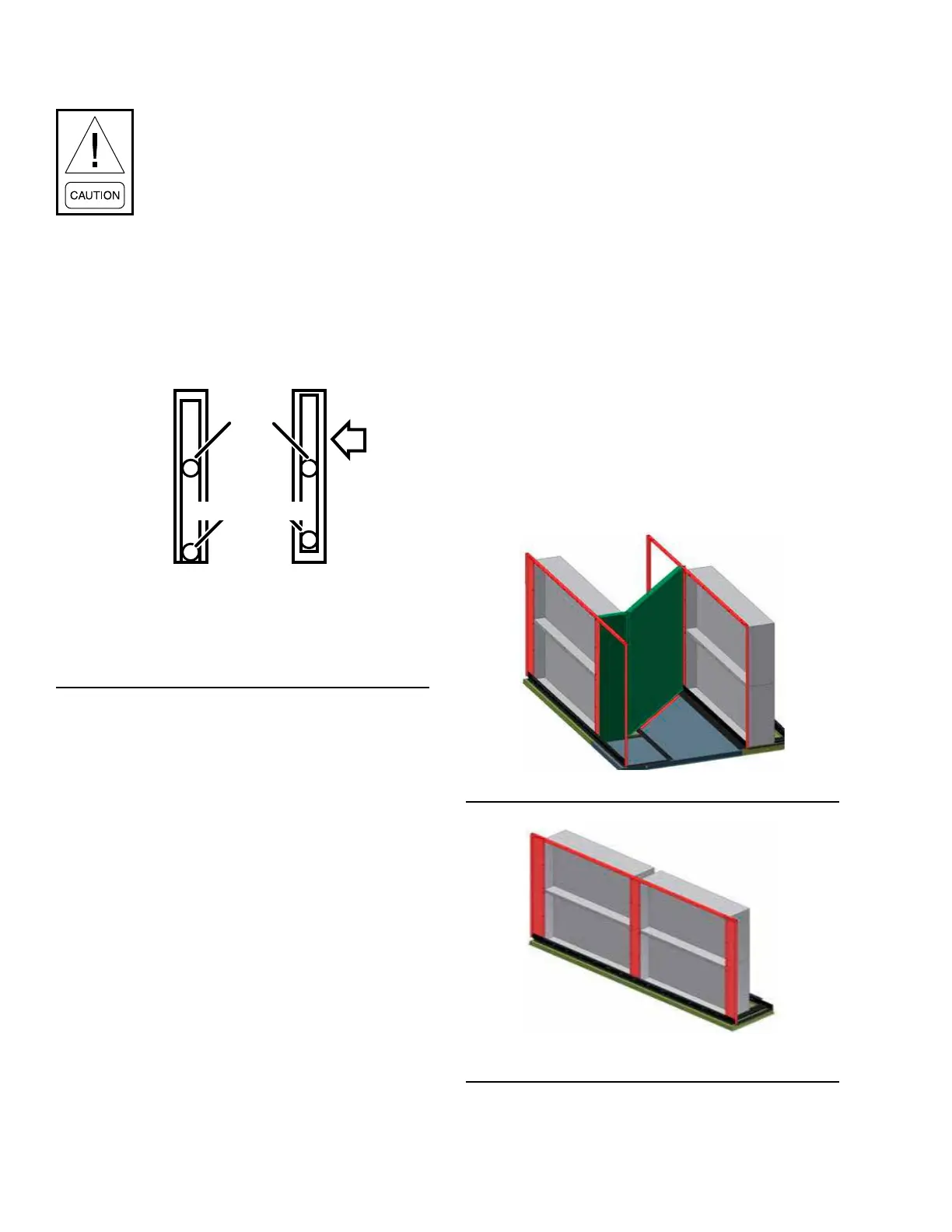

1. Consult the job specications and submittal

drawings for specic piping requirements, coil

connection sizes and location. The AHU should

be level to assure proper venting and draining of

coils. The piping arrangements must provide for

a balanced ow in multiple coil installations as

shown in Figure 115 on page 74.

FIGURE 115 - FACTORY COIL CONNECTIONS

LD06340

STEAM IN

CONDENSATE

OUT

SAME END

CONN

OPPOSITE

END CONN

SDC COIL

AIR

FLOW

2. Support all connecting piping independently of

thecoils.Provideswingjointsorexiblettings

in all piping connections, particularly adjacent to

heating coils to absorb expansion and contrac-

tion strains because rigid piping connections can

cause coil damage.

3. The coil supply and the return pipe connections

are labeled. When attaching the piping to the coil

header, make the connection only tight enough

to prevent leaks. Excessive tightening may cause

damage to the header.

Hold a backup wrench firmly on the coil con-

nection so that when tightening the connecting

piping, the torque is not transmitted to the coil

header, which could damage the coil connection.

Application Notes - All connections are male pip-

ing threaded except DX coils, which are soldered.

Drain and vent taps on water coils are pipe thread, and

shipped with plugs installed. These taps are installed

approximately two in. back from the end of the thread-

ed connections. Install the pipe for balanced flow and

to assure even airflow.

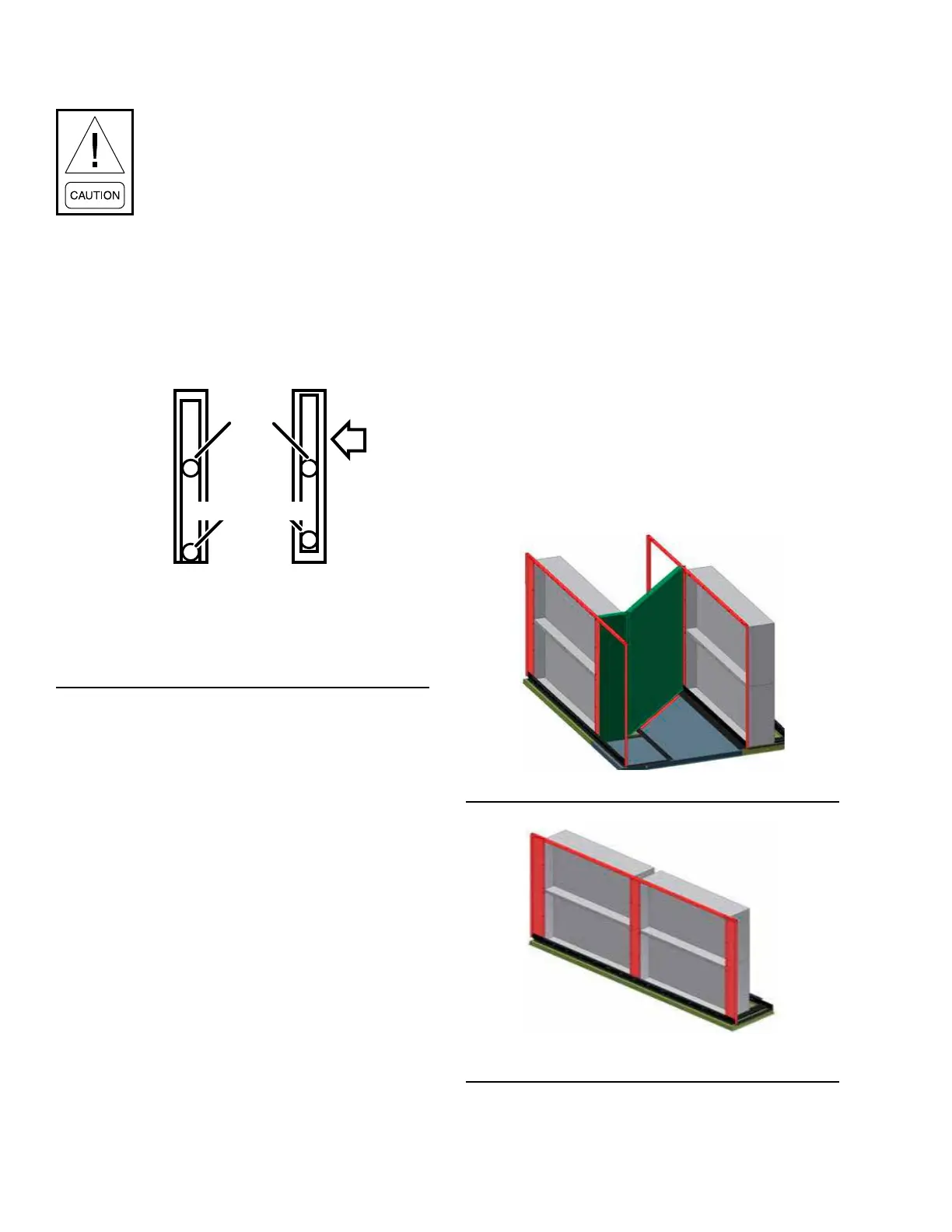

Staggered Coils

Staggered coils in the AHUs equipped with an optional

expanded cabinet will have connections brought to the

AHU exterior for liquid or steam coils as shown in Fig-

ure 116 on page 74 and Figure 117 on page 74.

DX coils are not included.

The external connections are a threaded pipe or grooved

pipe for the contractor to make his connections when

the media is liquid, or a threaded pipe when the media

is steam.

It's the installing contractor's responsibility to insulate

the piping extensions inside the AHU.

FIGURE 116 - STAGGERED COIL - ANGLED WALL

LD16561

FIGURE 117 - SPLIT COIL - OPPOSITE SIDE

CONNECTIONS

LD16562

Loading...

Loading...