JOHNSON CONTROLS

82

FORM 102.20-N1

ISSUE DATE: 7/06/2016

SECTION 3 - HANDLING, STORAGE, AND INSTALLATION

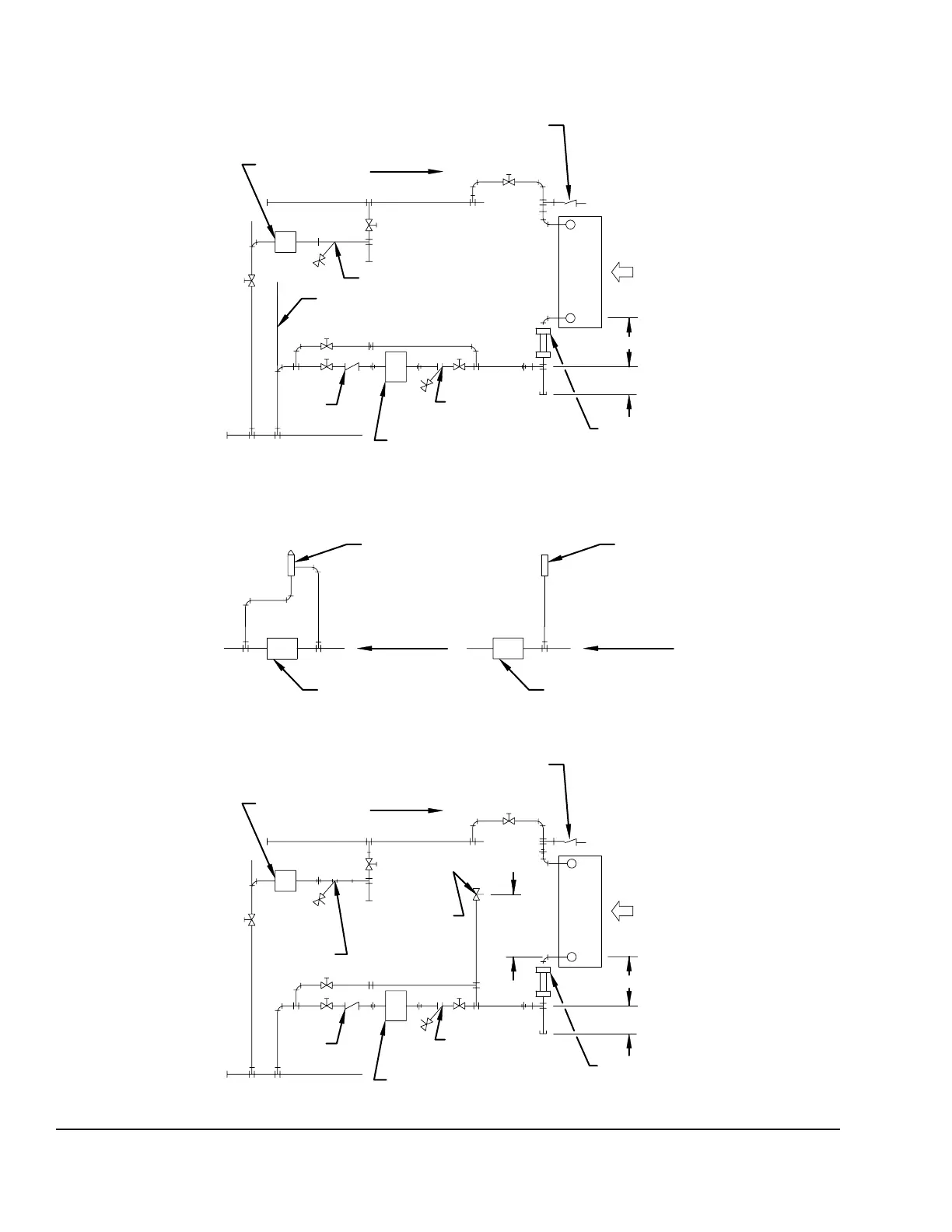

FIGURE 126 - STEAM PIPING FOR VIFB

LD09634

(STEAM PRESSURE BELOW 15 PSIG (103.4 KPa)

STEAM MAIN

DRIP TRAP

STEAM MAIN

VACUUM BREAKER CHECK VALVE

1/2 in (12.7mm)-15"

AIR FLOW

VIFB

COIL

STRAINER

AIR VENT TO ATMOSPHERE ON

OPEN GRAVITY RETURN SYSTEM

ONLY. MINIMUM 1 in (25.4mm) PIPE

T

T

STRAINER

RETURN MAIN

CHECK

VALVE

COMBINATION FLOAT

AND THERMOSTATIC

TRAP

FLEXIBLE CONNECTOR

8 in (203.2mm)

8 in (203.2mm) MIN

NON-VENTING TRAPS

(STEAM PRESSURE BELOW 15 PSIG (103.4 KPa)

1/2 in (12.7 mm)

THERMOSTATIC

TRAP FOR AIR

REMOVAL

NON-VENTING TRAP

NON-VENTING TRAP

CONDENSATE

FLOW

CONDENSATE

FLOW

3/4 in (19.1mm)

AUTOMATIC

AIR VENT

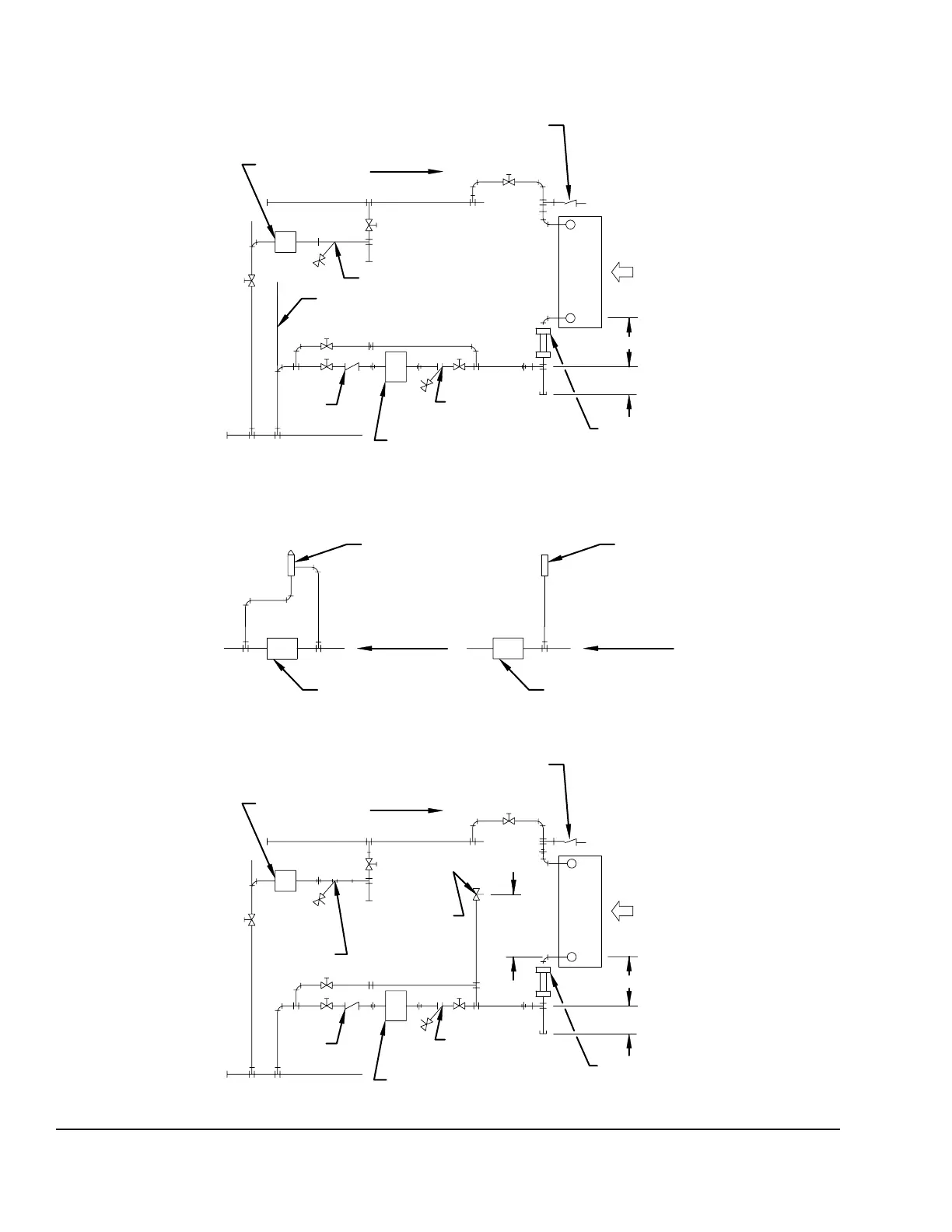

(STEAM PRESSURE ABOVE 15 PSIG (103.4 KPa)

VACUUM BREAKER CHECK

VALVE 1/2 in (12.7 mm)- 15"

STEAM MAIN

DRIP TRAP

STEAM

MAIN

STRAINER

1/4 IN (6.4 MM)

PETCOCK

CRACKED OPEN

FOR CONTINUOUS

AIR VENTING

T

T

CHECK

VALVE

STRAINER

INVERTED BUCKET TRAP

RETURN MAIN

FLEXIBLE CONNECTOR INSTALLED PARALLEL

TO COIL HEADER AND AS CLOSE AS POSSIBLE

TO COIL CONDENSATE CONNECTION.

AIR FLOW

8 in (203.2mm)

8 in (203.2mm) MIN

VIFB

COIL

12 in MIN.

(304.8 mm)

Loading...

Loading...