JOHNSON CONTROLS

87

SECTION 3 - HANDLING, STORAGE, AND INSTALLATION

FORM 102.20-N1

ISSUE DATE: 7/06/2016

3

THERMOSTATIC EXPANSION VALVES (TXV)

Each coil distributor circuit requires its own thermal

expansion valves (TXV), and condensing AHU circuit

requires its own liquid line solenoid valve (LLSV).

Equip TXVs with external equalizer tubes that are field

connected to the suction line. Size the valve according

to the valve manufacturer's recommendations, allow-

ing approximately 35 psi ( throughout the coil and dis-

tributor at full load).

Do not oversize the valve. Follow the valve manufac-

turer's instructions to find the thermostatic bulb. Proper

expansion valve operation is necessary in order to real-

ize the rated coil capacity.

When a DX type coil is operated with a suction temper-

ature below 32°F, a buildup of frost will occur on the

finned surface. It is not recommended to operate DX

coils for air conditioning purposes at below freezing

suction temperatures. If the full load operating point

for the coil is selected at a safe temperature, a system

analysis is required to check for the lowest probable

suction temperature at light load conditions.

HOT GAS BYPASS (HGBP)

When using discharge air temperature control or sys-

tems with outside air economizer cooling, always in-

clude hot gas bypass (HGBP). It is not as critical to

use HGBP with return duct air temperature or suction

pressure control, but it provides better capacity control

at low loads.

The Venturi type distributor furnished with the DX

coils may be ordered for field application of an HGPB.

The connection may be made through a tee installed

in the field between the expansion valve and distribu-

tor. The system balance point and control adjustments

must assure compressor cooling and avoid excessive

compressor cycling. Refer to Guidelines for Proper

Application Piping and Split Systems (Form 050.40-

ES3) for compressor staging solutions.

DX COIL CIRCUITING AND STAGING

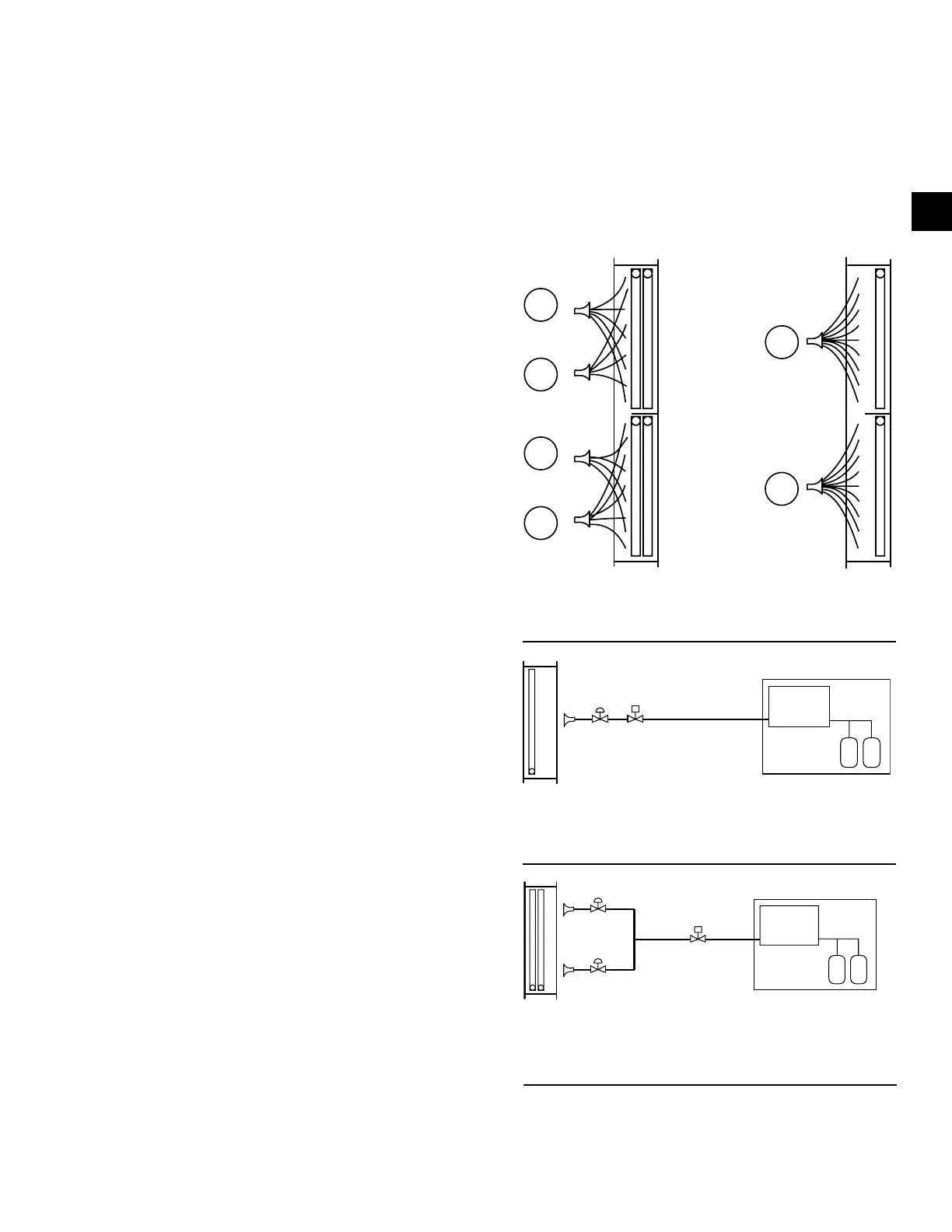

On stacked coils, use a minimum of four coil circuits

to achieve full face control as shown in Figure 133 on

page 87. When the condensing AHU has two com-

pressors per refrigerant circuit, one or two coil circuits

may be used for each refrigerant circuit, depending

upon the cooling capacity.

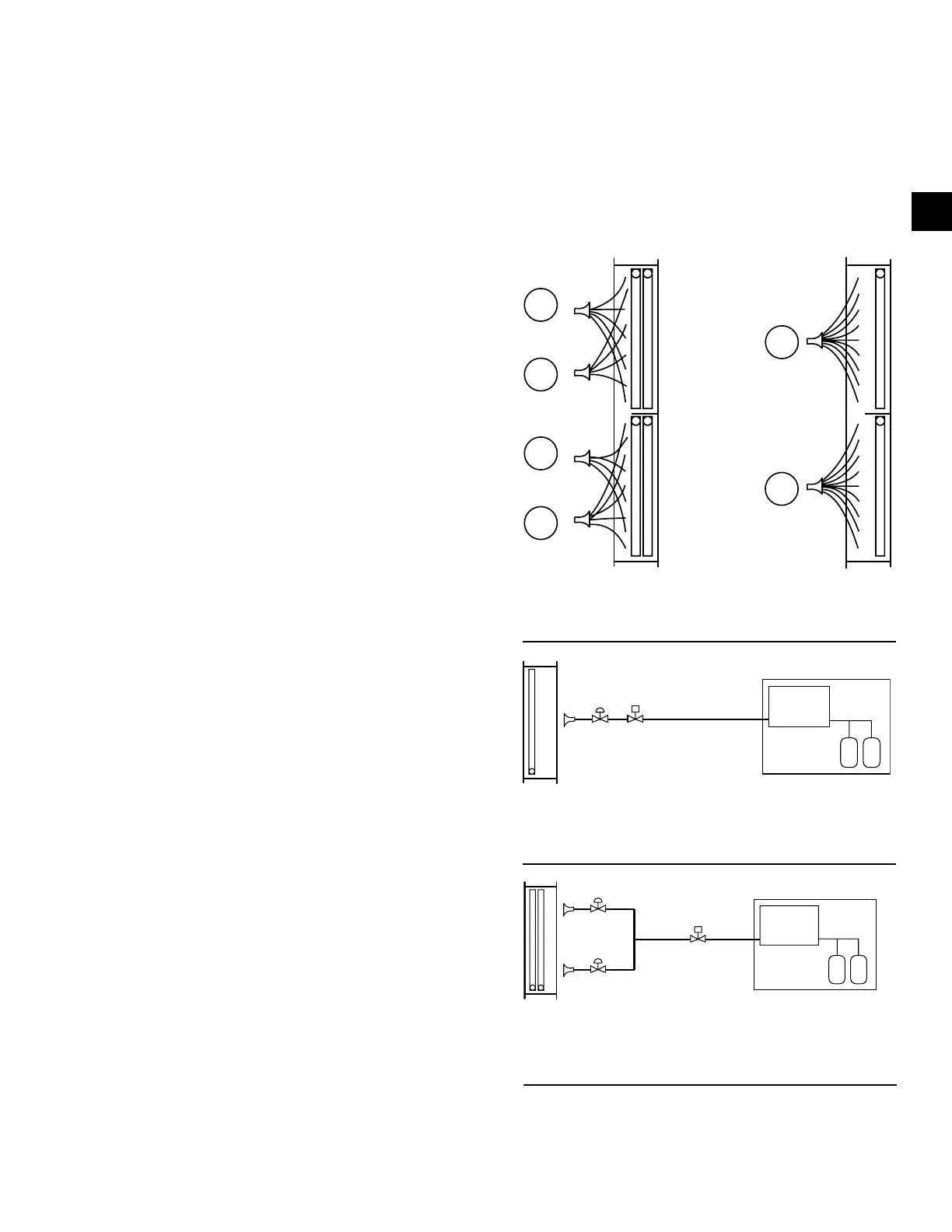

If one coil circuit is used as shown in Figure 134 on

page 87, the LLSV and TXV must be sized to handle

the full capacity of the refrigerant circuit. When two

coil circuits are used per refrigerant circuit as shown in

Figure 135 on page 87, each TXV should be sized

to handle half of the capacity of the refrigerant circuit,

and the LLSV should be sized to handle the full capac-

ity of the refrigerant circuit.

2

4

1

3

1

2

FIGURE 133 - STACKED COIL CIRCUITING

LD09147a

Four Circuits

Recommended

Two Circuits NOT

Recommended

FIGURE 134 - ONE COIL CIRCUIT PER

REFRIGERANT CIRCUIT

LD09148

100% Capacity

DX Coil

Condensing Unit

FIGURE 135 - TWO COIL CIRCUIT PER

REFRIGERANT CIRCUIT

LD09149

DX Coil

Compressor #1

TXV

Compressor #2

TXV LLSV

Condensing Unit

Loading...

Loading...