18

Surface Mounting

Wall (surface) mounting is used where flush mounting is inapplicable (in concrete and

steel structures, entry barrier columns, etc.). The frame is not used.

Caution

If there is a risk of vandalism (in public garages, e.g.), use steel fixing

elements instead of the dowels and screws included in the delivery.

Be sure to insert plugs into unused bushing holes to avoid water leakage

during facade cleaning, for example. Never leave the holes open for even a

short time (one day delay between mounting and cable connection, e.g.).

Safety Warning

Eliminate the risk of accident! Wall mounting is not suitable for narrow

passages or places where people’s attention may be distracted. The

manufacturer shall not be liable for injuries incurred as a result of unsafe

mounting!

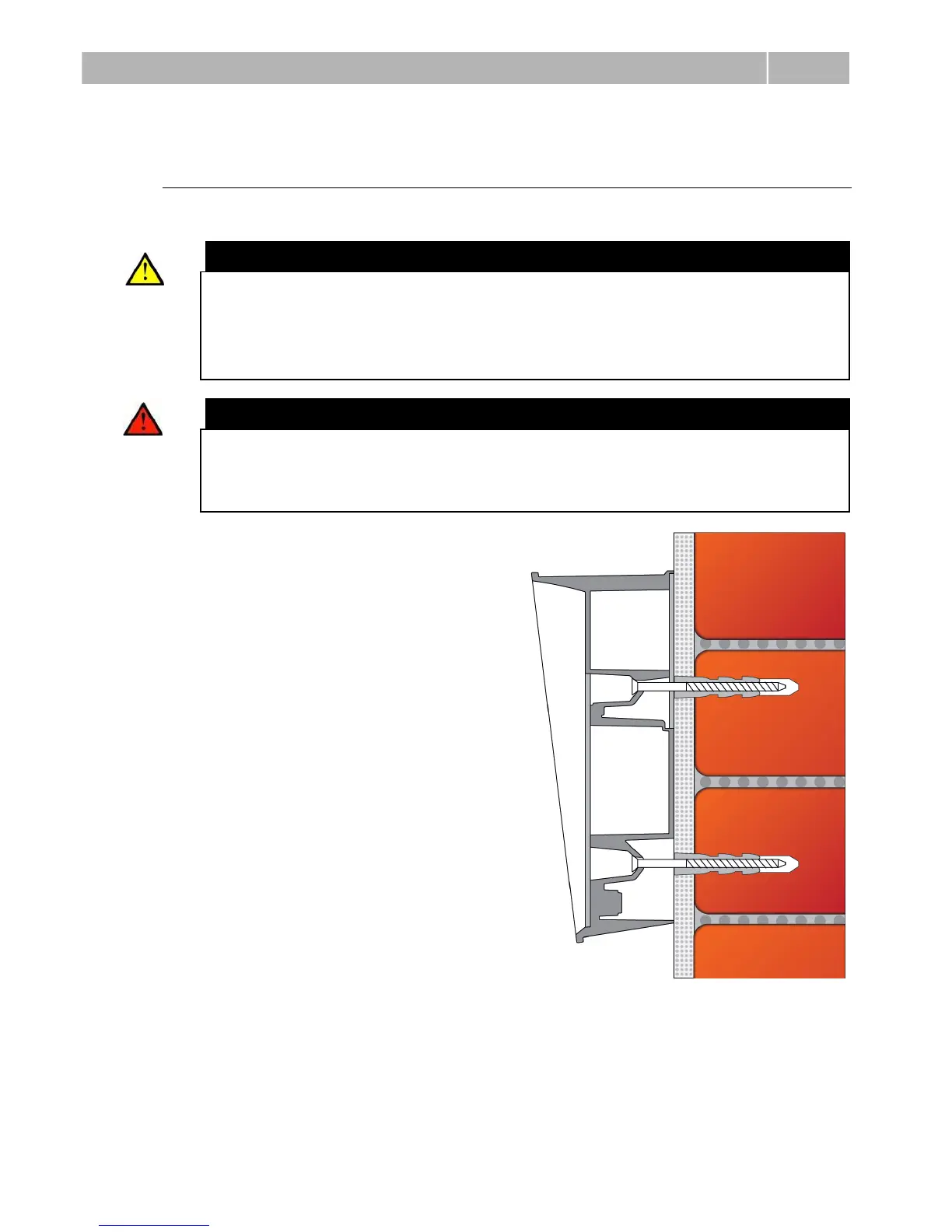

1. Select the 2N® Helios IP Safety

position with respect to the supply

cables. Where the cables are installed

inside a structure or wall, use the hole

at the intercom bottom.

2. Drill holes of the depth of 60 mm for

dowels in the wall as shown in the

figure. Push or hammer the enclosed

dowels into the drilled holes. Use

some suitable building adhesive if the

dowels are too loose. Use fixing

elements of your own for steel

structure surface mounting (metric

screws + nuts, e.g.).

3. Remove the front panel from the

intercom.

4. 2N

®

Helios IP Safety has bushings

already mounted. Replace it with

plugs, if unused.

5. Put the intercom on the wall/structure

while introducing cables inside. Leave

some of the cables inside the unit as a

reserve. Insert the plugs in the

unused bushings and tighten the

bushing nuts carefully.

6. Do not complete mounting until you have finished electrical installation – refer to

Mounting Completion. Where cables lead along the surface, use the bushings

included in the delivery.

Loading...

Loading...