3D Systems, Inc.

p/n: 15-D100, rev. D

Caution: 3D Systems strongly recommends that the following cleaning instructions are performed either at

the end or before every print job as to ensure the DMP Factory 350 system remains operational as long as

possible.

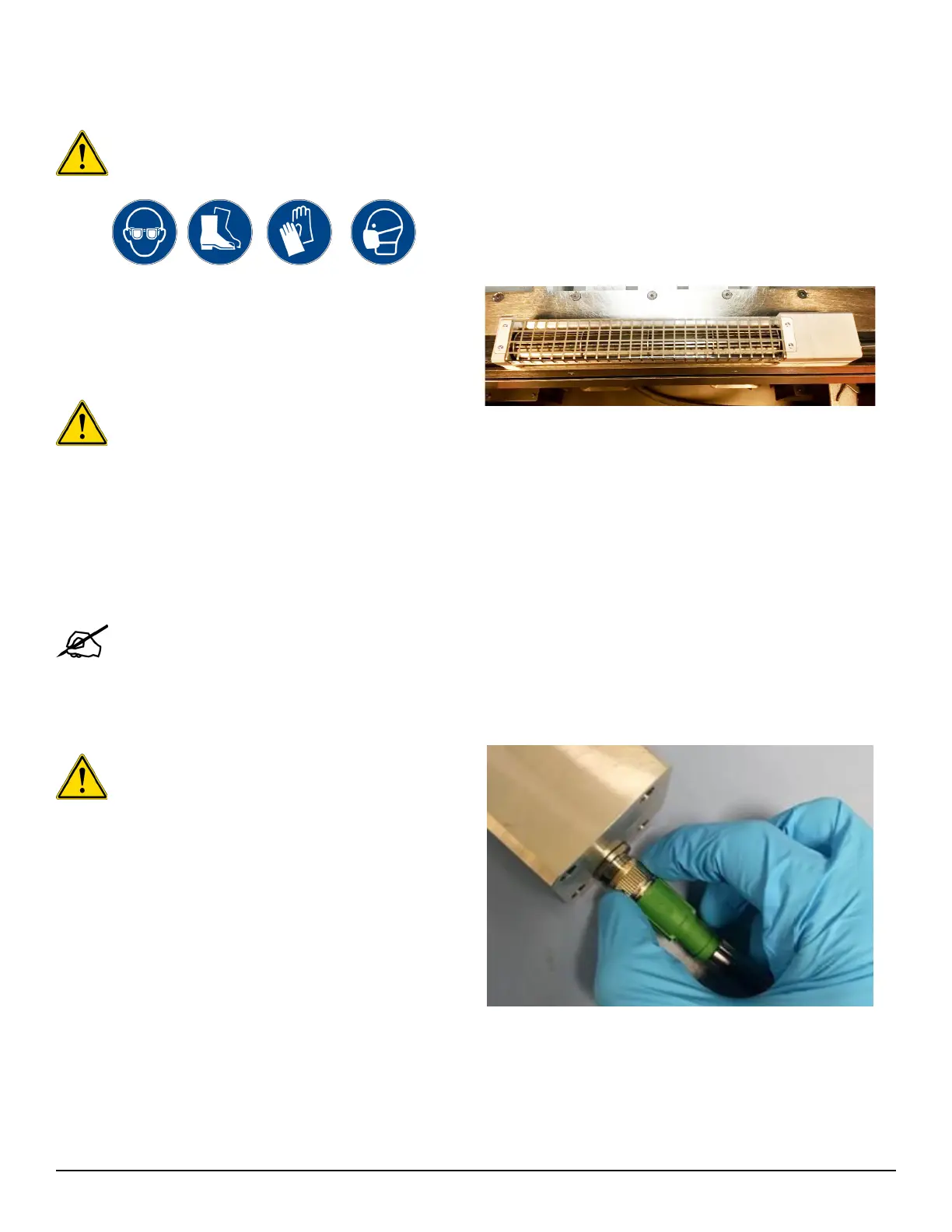

WARNING: ANY POWDER THAT IMPEDES ROTATION

OF THE RPM BLOWER SHOULD BE REMOVED.

COMPRESSED AIR MAY BE USED TO CLEAN THE RPM

BLOWER BUT:

MAKE SURE THE COMPRESSED AIR IS PURIFIED, OIL

MAKE SURE TO CAPTURE THE POWDER BLOWN

OUT OF THE RPM BLOWER WITH A WET-SEPARATOR

VACUUM CLEANER.

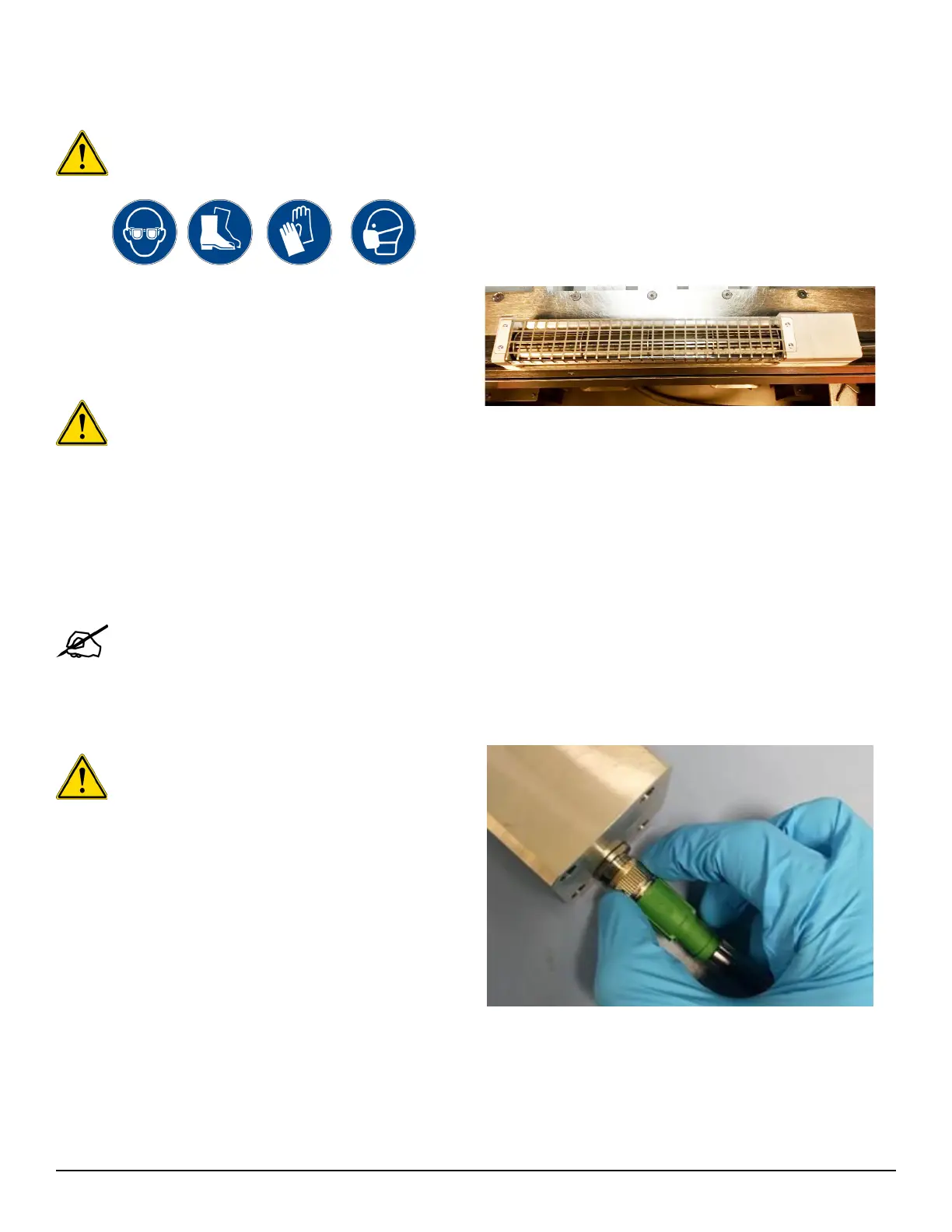

Note: If no compressed air is available at the

system, it is possible to disconnect the RPM

switch, disconnect the Murr connector and clean

reconnecting the Murr connector, turn back on

the 24V DC main switch.

WARNING: PAY SPECIAL CARE TO AVOID ANY

POWDER CONTAMINATION WHEN RECONNECTING

THE MURR CONNECTOR.

Loading...

Loading...