3D Systems, Inc.

10

SYSTEM DELIVERY

After placing your order, a 3D Systems representative will contact you to schedule your shipment delivery date. Ensure that the

area into which you intend to place your SLA system is ready, and that you have appropriate forklifts or other lifting devices

before scheduling the installation of your system by a 3D Systems representative. The following information will guide you

through this preparation phase.

5

PREPARATION FOR RECEIVING

Being that the ProX 800 crate is quite large, have an adequate forklift available before you begin to unload the crate from the

shipping truck. Make sure that the available forklift, or other lifting device, can handle the load during unloading and during

uncrating. Refer to the illustration, “Forklift lift points - ProX 800 Printer” on page 12 for locations and dimensions for the

forklift.

NOTE: Crates can only be unpacked by, or under the supervision of, a 3D Systems Customer Support Engineer.

3D Systems accepts no responsibility for missing items if crates are opened without an authorized Customer

Support Engineer present supervising this procedure.

Inform your receiving personnel that these crates will be arriving and arrange for a location to store them in until your

appointment with a 3D Systems Customer Support Engineer.

Inform your receiving personnel that the crates allow forklift access from the side to make sure they can be properly unloaded

or moved to your warehouse until the 3D Systems representative is scheduled to install the systems.

If you do not have an adequate forklift on-site, contact the shipping company in advance of the shipment to discuss whether

one is needed for receiving the shipment.

NOTE: The forklift must have a minimum of 1.8m (6 ft) forks for safe and stable transport, but we recommend

2m (6.5 ft).

It must be rated for the weight of any of the components you ordered. The lift loops are designed to accept 1.5 in (38 mm) thick,

4 in (approximately 100 mm) wide forks. Fork extensions will not t in the lift loops on the machine frame. Review the charts

below for crated dimensions and weights of the components.

SHIPMENT ARRIVAL

The ProX 800 system will arrive in a variety of crates and/or pallets - the largest crate being the ProX 800.

Once your shipment arrives, rst inspect the crates for any physical damage. Then, after inspection, receive the crates.

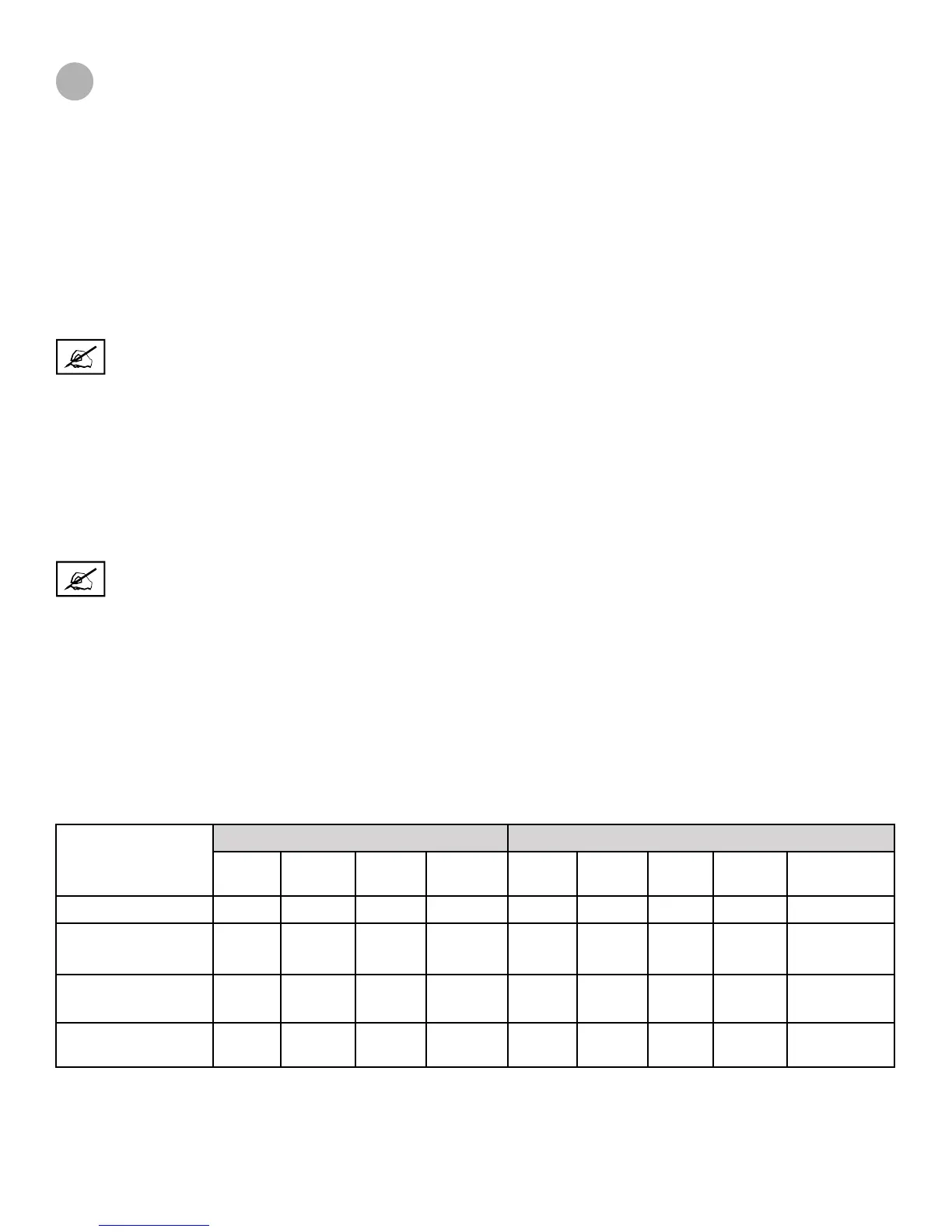

The following chart lists both crated and uncrated dimensions and weights for every possible crate that you may have ordered.

Verify your order and compare to the listed items below. Crates or pallet dimensions and weights may vary.

Crated Specications Uncrated Specications

Width Depth Height Weight Width Depth Height Weight Weight range

w/ resin

Description cm (in) cm (in) cm (in) kg (lb) cm (in) cm (in) cm (in) kg (lb) kg (lb)

ProX 800 191 (75) 165 (65) 249 (98) 1724

(3800)

137 (54) 160 (63) 226 (89) 1497

(3300)

n/a

Laser Unit

(laser, power supply)

94 (37) 64 (25) 89 (35) 91 (200) 19 (7.5) 53 (20.9) 17 (6.7) 22.7 (50) n/a

Manual Ooad Cart 127 (50) 174

(68.5)

157.5

(62)

160 (350) 76

(29.8)

140

(55.1)

118

(46.3)

90 (200) n/a

Weight and Dimensions - System Components

(continued on next pg. 11)

Loading...

Loading...