3D Systems, Inc.

12

Required Equipment

• SLA part post-processing equipment and supplies. Refer to the section, “Support equipment which includes, but is not

limited to” on page 13.

• Safety equipment. Refer to the section, “Recommended safety equipment and supplies” on page 13.

• One or more Windows 7-equipped workstations. At least one system must be available at installation time to load this

computer with 3D Systems’ 3DManage software. Ask your 3D Systems representative about loading this software in

advance of your installation appointment.

Optional Equipment

• Uninterruptible Power Supply (UPS) and any miscellaneous cables or cords - minimum rating of 5kVA for the ProX 800.

• Functioning network connection for a computer to the SLA system. If no network is available, ensure a computer is in

close proximity to the SLA system during your installation appointment.

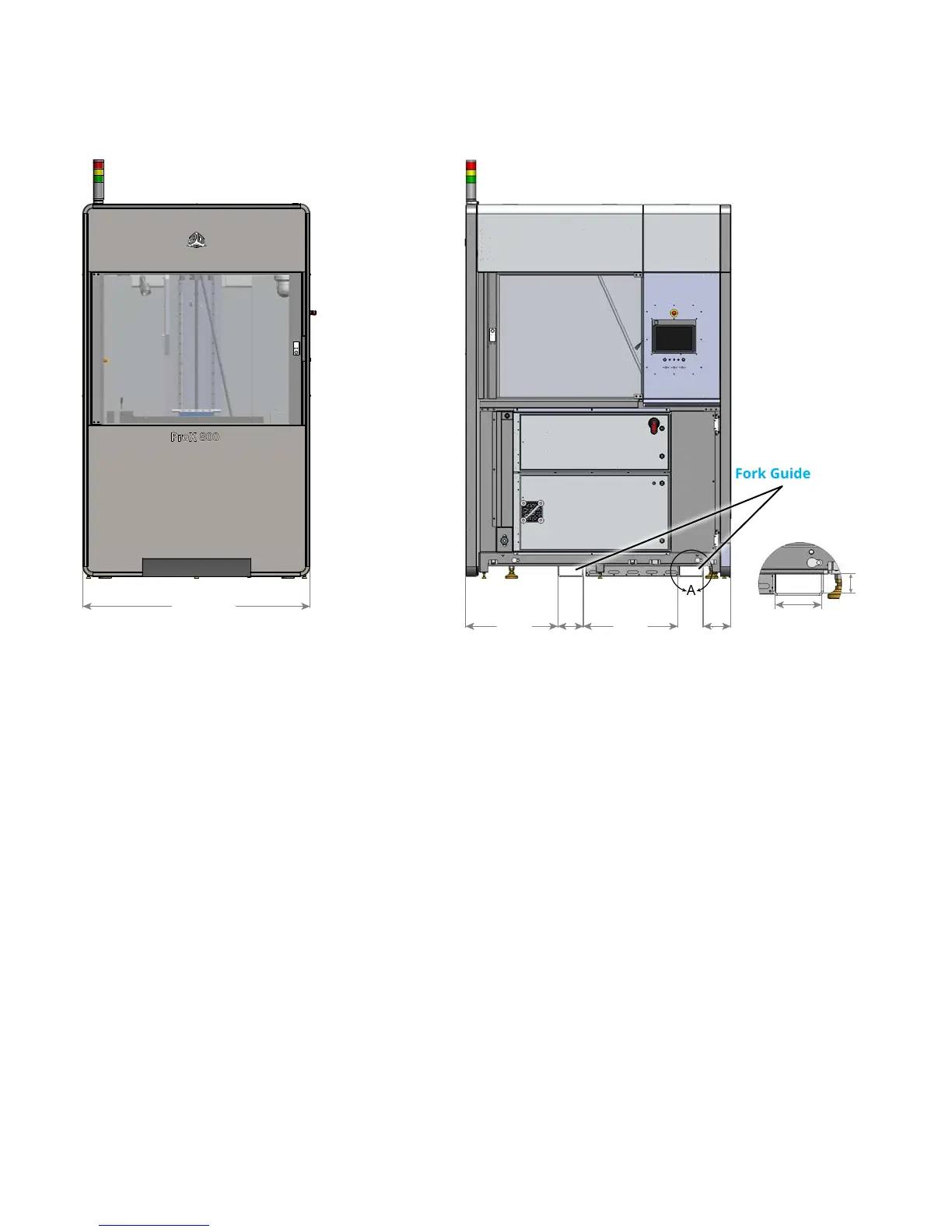

53.9in

1370mm

21.9in

556mm

6in

152mm

22.5in

572mm

6.6in

168mm

5.5in

140mm

2.3in

57mm

A

DETAIL A

Third Party Supplies and Equipment

Third party supplies and equipment are purchased from parties other than 3D Systems. These components are recommended

or required for full post-processing capability. These items should be found and delivered prior to the installation of your ProX

800. Your 3D Systems representative can offer guidance regarding optimal placement and location of this equipment.

For a partial list of providers for this equipment, refer to “Appendix C: Third Party Supplies and Equipment” on page 18.

These supplies, accessories, and equipment provide SLA system owners with complete part-building, processing, and nishing

capability.

Forklift lift points - ProX 800 Printer

TRANSPORTING THE ProX 800

When the 3D Systems Field Engineer arrives, and the crate is opened, use a forklift to lift the system. Refer to the following

diagram illustrating the forklift points.

Minimum length of forks is 6 ft (1.8 m)

Recommended length is 6.5 ft (2 m)

Fork Guides

Loading...

Loading...