3D Systems, Inc.

3

SITE SELECTION - ProX 800

This section provides the requirements and recommendations to determine the most appropriate location for a highly

functional, ecient ProX 800 workspace, with room for other equipment and supplies.

To help you choose a location, refer to “Appendix A: Initial Site Survey Checklist” on page 16. This checklist provides the

attributes that you need to select the best location for your installation.

After narrowing the list of possible locations, consider each requirement carefully before making a decision about your nal

placement site.

3

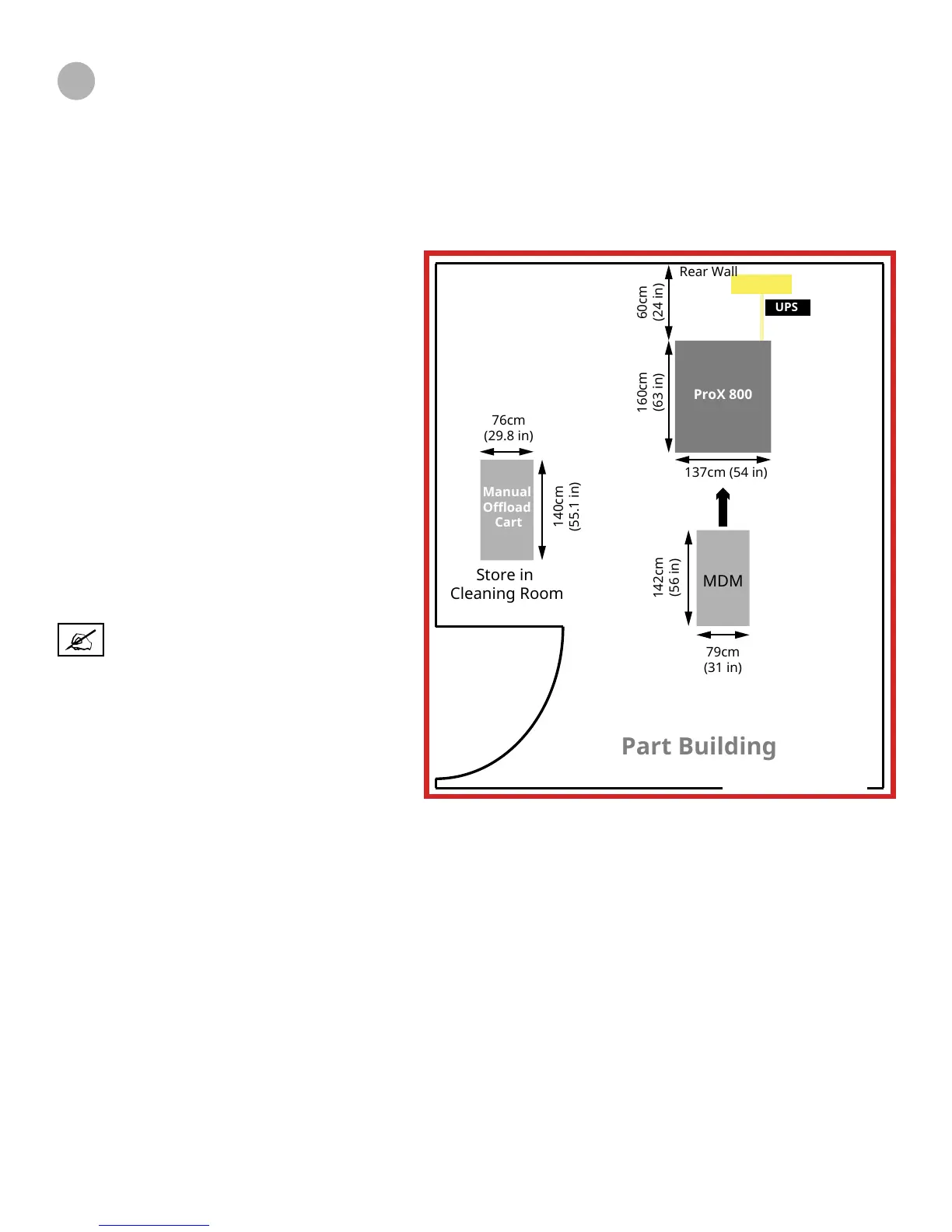

SPACE REQUIREMENTS

User preferences, building codes, and equipment

conguration help you to dene the total oor

area that your ProX 800 will need. The SLA system

should be located in an environmentally controlled

room. Locate the secondary post processing

equipment and supplies in an adjoining room

or rooms, if possible. User preferences, building

codes, required storage space, and other factors

inuence total room area. The illustration at

the right shows an ideal site conguration that

minimizes the required movement of parts after

printing. To leave ample room for access to the

rear of the unit, set the ProX 800 24in (60cm) away

from the rear building wall.

The illustrations, “ProX 800 system space

requirements” on page 4 show the minimum

dimensions of the ProX 800 system. Your site

layout will vary.

NOTE: Due to laser safety requirements,

the system should be located where

access to the room can be avoided

during service calls.

Optimal Site Layout

FLOOR AREA/SURFACE

Floors and counter spaces in the SLA work area should be non-porous and suitable for cleaning with solvents. The feet of

the system must be on a non-resilient surface such as bare concrete. Carpeted oors must not be used. Remove any ooring

where the feet of the SLA system will be placed. The system should not straddle any oor seams. The maximum permissible

oor incline is 2.5cm/12m (1 in/40 ft).

FLOOR VIBRATION AND SHOCK

To ensure part quality and accuracy, choose a ground oor location with a thick concrete pad, which will minimize vibration.

SLA equipment is slightly self-damping, and should not be affected by normal or incidental environmental vibration; however,

the area should be isolated, either via location or some other physical or mechanical means, from any signicant internal or

external vibration sources such as heavy machinery, airplanes, or trains, which could cause unacceptable shock or vibration

levels.

It is recommended that the amount of vibration/shock from the oor not exceed the SPIE 1991 VC standards of VC-A. This

corresponds to a max oor velocity of 50 m/sec over a 4-80Hz bandwidth. Users are responsible verify the level of vibration in

their facility.

Power

UPS

Part Building

ProX 800

MDM

Manual

Offload

Cart

Store in

Cleaning Room

60cm

(24 in)

160cm

(63 in)

142cm

(56 in)

140cm

(55.1 in)

137cm (54 in)

76cm

(29.8 in)

79cm

(31 in)

Rear Wall

Loading...

Loading...