29

For boxes which are fully packed with products that

support the top fl aps, the adjustment of this regulator is

not critical since the boxes can support the pressure of

the upper frame (drive belts) at a wide range of regulator

settings. However, if under-fi lled or fragile boxes are to

be sealed, this regulator can be used to set the upper

frame to a higher pressure that is adequate for conveying

the box through the machine while also allowing the

upper assembly to descend on box and preventing box

damage.

Note – A precision regulator is used to balance the

upper drive assembly. Due to the self relieving

feature of this regulator a small amount of

air will continually vent to the atmosphere.

This is normal and amounts to approximately

3 liter/min [0.1 SCFM ].

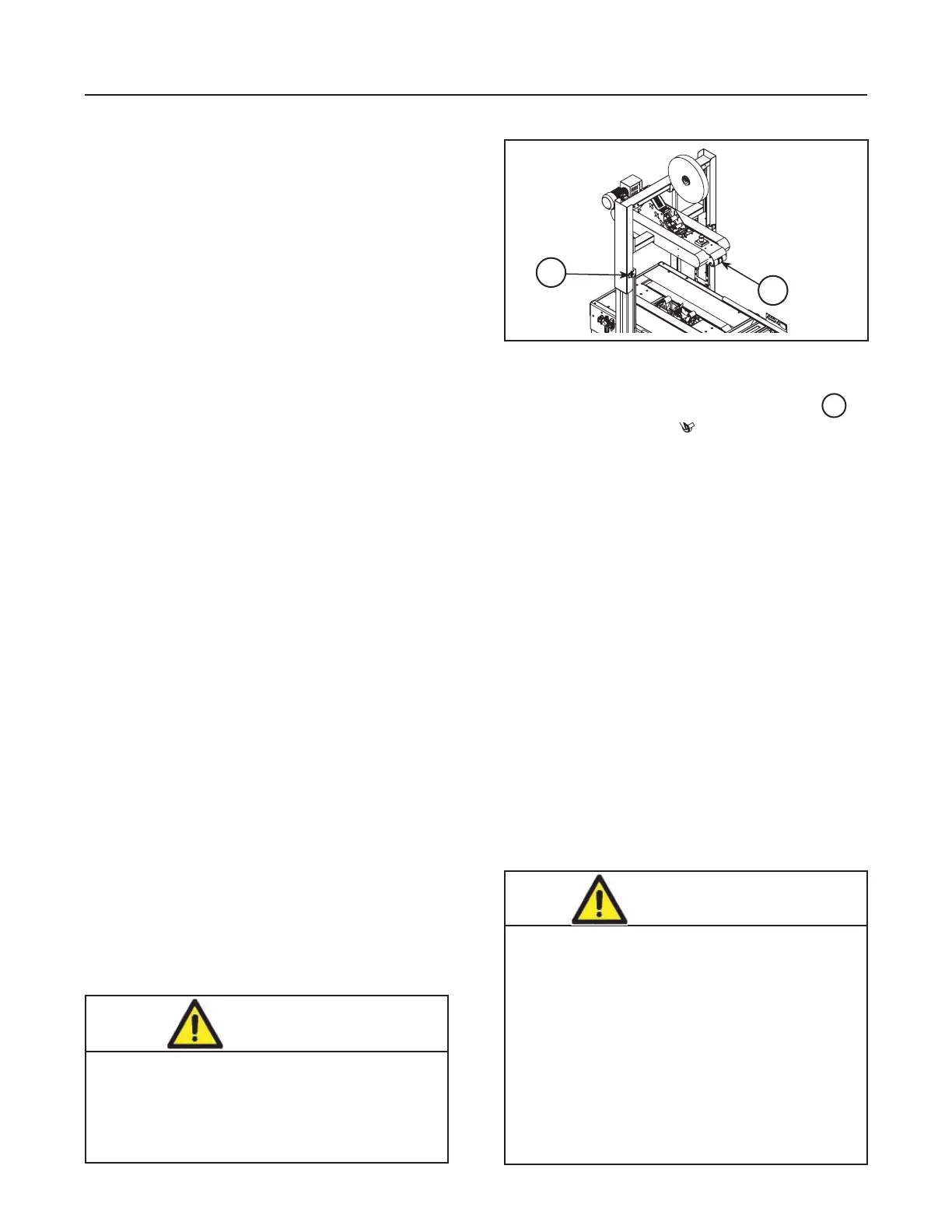

Figure 7-17

Mechanical Latch

8. Main Air Pressure Gauge - Indicates main air regula-

tor pressure setting. Air regulator should be adjusted

so gauge reads 5 bar gauge pressure [70 PSIG].

9. Mechanical Latch, Upper Drive Assembly

(Figure 7-17)

The mechanical latch is provided to hold the upper

drive assembly at the fully raised position for tape

threading and maintenance.

To raise and latch the upper drive assembly:

1. Push and hold upper frame raising switch "A".

2. Push and hold latching knob "B".

3. Release switch "A".

4. Release knob "B".

5. Shut off air supply.

To release and lower the upper drive assembly:

1. Turn on air supply.

2. Push and release switch "A".

B

A

7-INSTALLATION AND SET-UP (continued)

Important – Before turning drive belts on, be sure

no tools or other objects are on the

conveyor bed.

• To reduce the risk associated with

pinch and entanglement hazards:

− Always feed boxes into the machine by

pushing only from the end of the box

− Keep hands clear of the upper head

support assembly as boxes are

transported through the machine

• To reduce the risk associated with

pinch and impact hazards:

− Keep away from the pneumatically controlled

upper drive assembly and box centering

guides when air and electric supplies are on.

CAUTION

CAUTION

• To reduce the risk associated with

pinch and entanglement hazards:

− Keep hands, hair, loose clothing, and

jewelry away from moving belts and

taping heads

2014 June

10. Upper Drive Pressure Gauge

As indicated in Air Pressure Regulator / Gauge,

Upper Drive Assembly Force Adjustment ,

The Upper Drive Pressure Gauge is used as an

indicator of "counter balance force" that equal-

izes air pressure on the Column Cylinders and

keeps Upper Assembly from dropping too quickly

from the raised position. Adjust the force higher (+)

or Lower (-) to equalize and create this balance.

11. Electrical Control Box - Houses DC Power

Supply for Proximity Sensors, Control Relays,

Motor(s) Contactor, and opening delay timer for

Box Centering Guides.

12. Push Button Station "Start/Stop"

Controls Box taping Cycle / Starts and Stops

Drive Belts.

7

7.16 Tape Loading/Threading - See Manual 2 or 3.

Note – If lower tape drum is mounted in alternate lower

outboard position, remove taping head from

machine bed by pulling straight up, insert threading

needle in taping head and replace taping head.

Install tape roll on drum (adhesive on tape leg up),

thread tape under knurled roller on outboard

mount, then attach tape to threading needle and

pull tape through taping head with threading needle.

Loading...

Loading...