USER’S MANUAL

Chapter 4 INSTALLATION

THE FOLLOWING OPERATIONS MUST BE

PERFORMED EXCLUSIVELY BY SPECIALISED

TECHNICAL STAFF WITH AUTHORISATION FROM

THE MANUFACTURER OR LICENSED DEALER. IF

THESE OPREATIONS ARE PERFORMED BY OTHER

PERSONS, SERIOUS PERSONAL INJURY AND/OR

IRREPERABL DAMAGE TO THE LIFT UNIT MAY

RESULT.

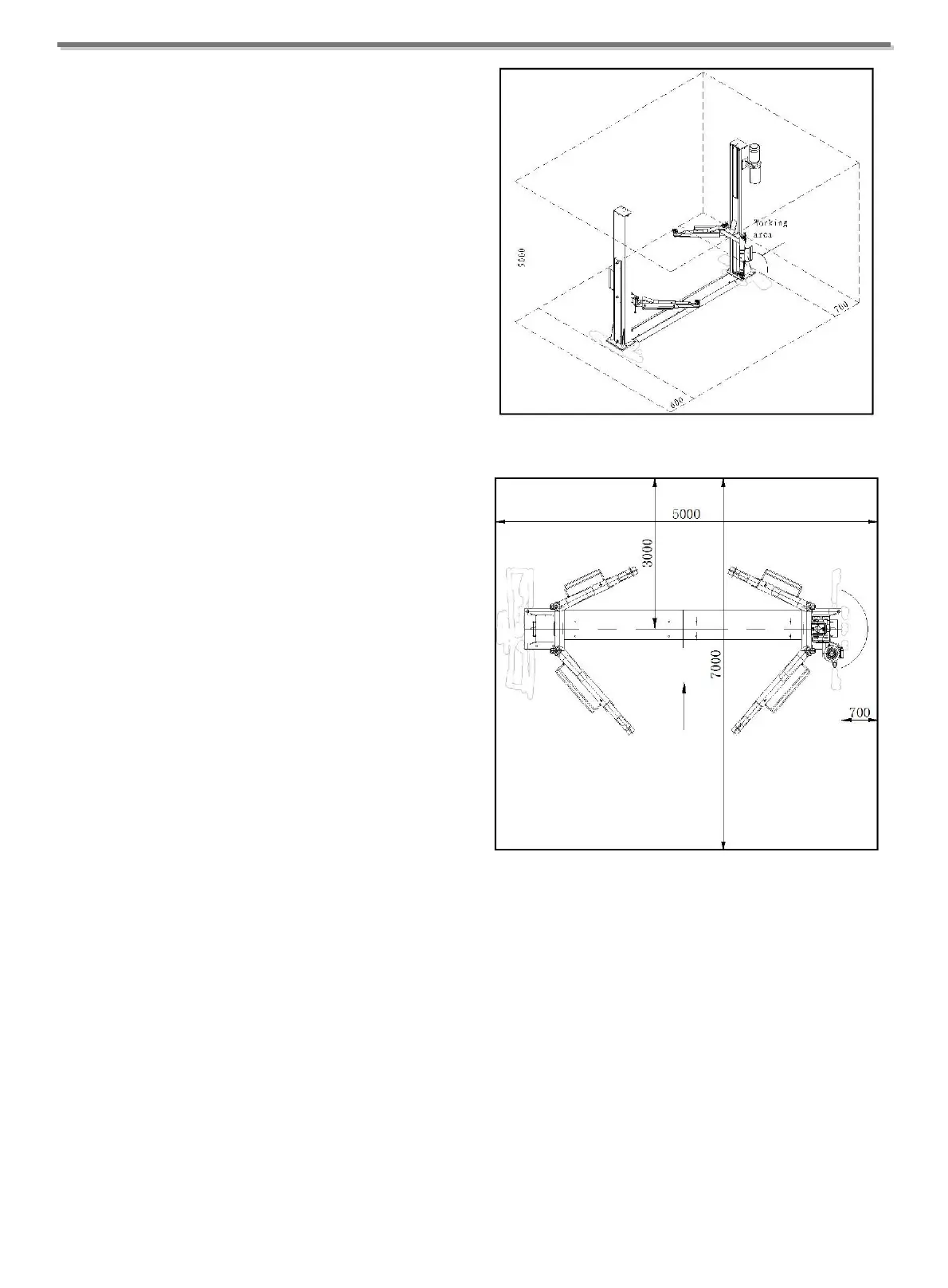

4 . 1 I N S T A L L A T I O N R E Q U I S I T E

CHECKLIST

The lift is designed for installation in enclosed areas

suitably protected from the weather. The place of

installation must be well clear of areas destined to washing

or painting, and away from solvent or paint storage areas or

areas where there is a risk of potentially explosive

atmosphere.

SUITABILITY OF THE DIMENSIONS OF THE

PLACE OF INSTALLATION AND SAFTY

CLEARANCE.

The lift must be installed in observance of the clearances

between walls, pillars, other machines, etc. indicated in Fig.

27 and incompliance with any legislative requirements in

the county of installation.

Check in particular:

◆ Minimum height: 5000mm inclusive of height of

vehicle, maximum height of arms, (i.e. 1900mm), and

upper post height (i.e. 2828mm)

◆ Min. distance from walls: 600mm

◆ Min. working area: 700mm

◆ Area for command station

◆ Area for maintenance, access and emergency escape

routes.

◆ Position in relation to other machines

◆ Proximity to power supply for trouble-free hook-up

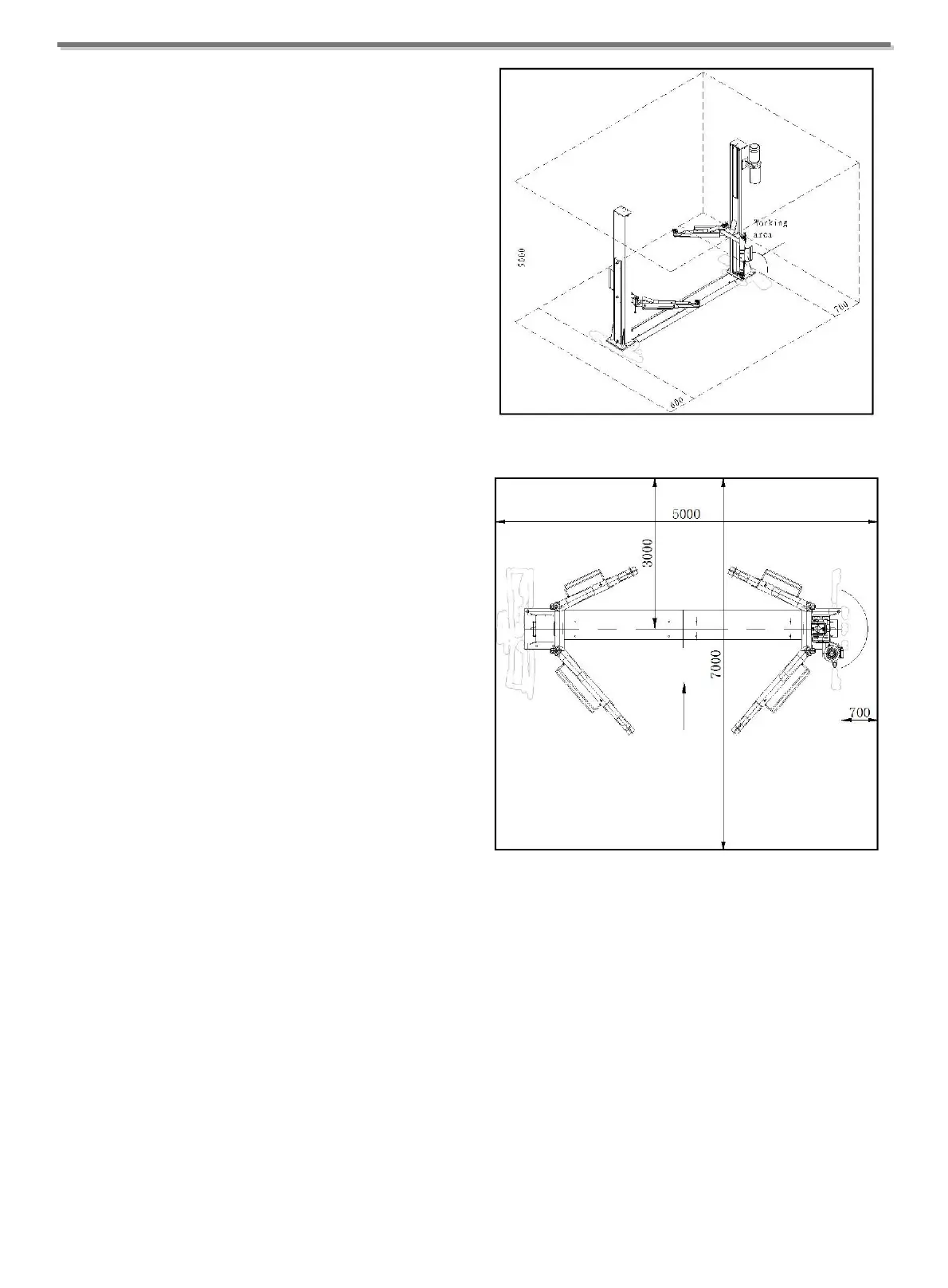

Fig. 27

Fig. 28

4.2 LIGHTING

All parts of the machine must be uniformly lit with

sufficient light to assure that the adjustment and

maintenance operations specified in the manual can be

performed, and without areas of shadow reflected light,

glare and avoiding all situations that could give rise to eye

fatigue.

The lighting must be installed in accordance with the laws

in force in the place of installation (responsibility lies with

the lighting equipment fitter).

-11-

Loading...

Loading...