USER’S MANUAL

warehouse for an extended period of time. Oil should be

disposed as indicated in Appendix A, Page 21.

AFTER EACH MAINTENANCE OPERATION, THE

MACHINE MUST RETURN TO ITS INITIAL

CONDITIONS, INCLUDING THE DISASSEMBLEED

PROTECTION AND SAFETY DEVICE.

To ensure good maintenance, it is important:

◆ To sue only tools that are suitable for the job and

original spare parts

◆ Follow the minimum maintenance schedule as

indicated

◆ Immediately find the cause of any abnormalities

(excessive noise, overheating, leaking fluids, etc)

◆ Pay special attention to lifting parts (cylinders) and

safety devices

◆ Use all the documentation supplied by the

manufacturer (wiring diagrams, etc)

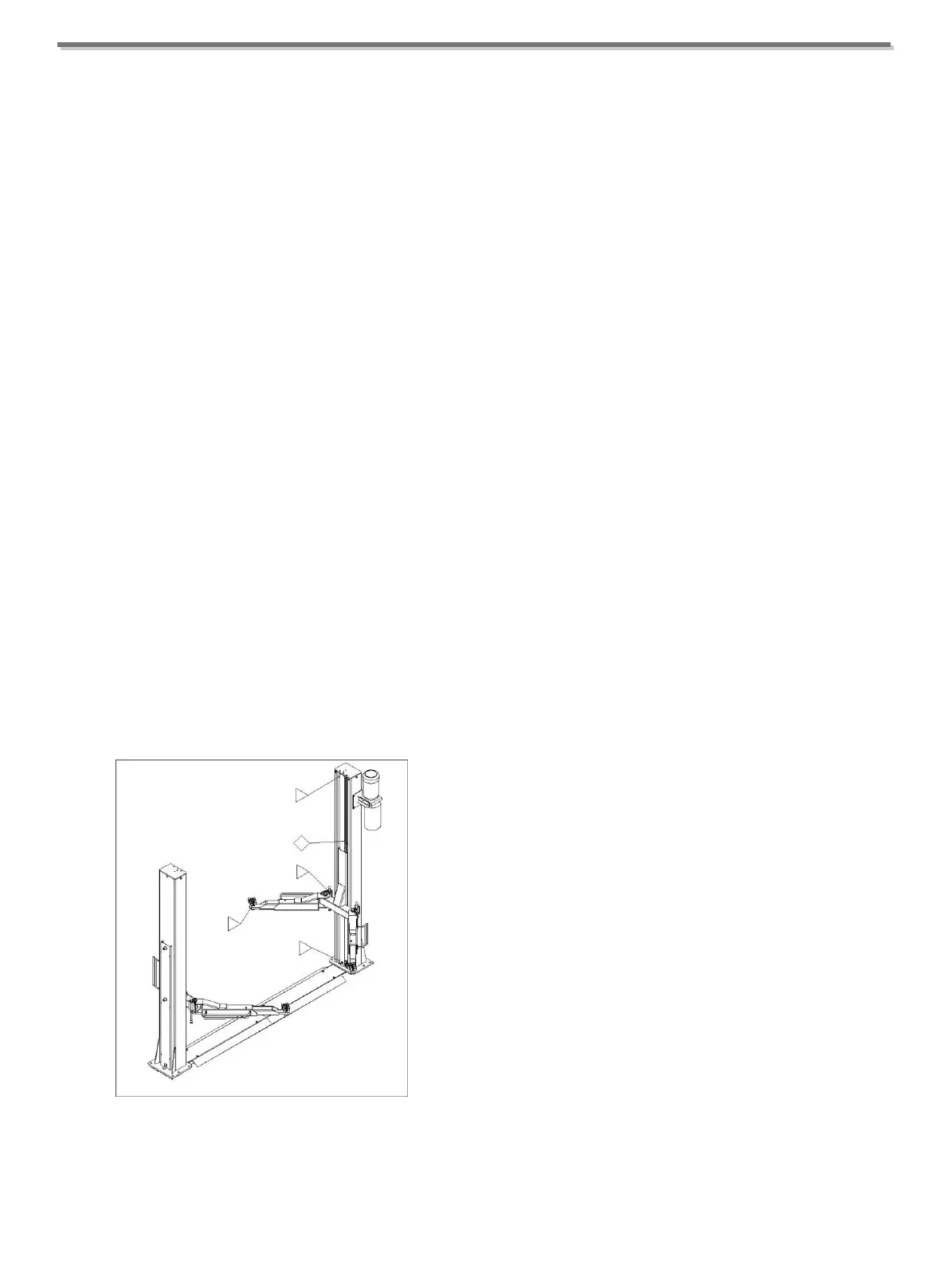

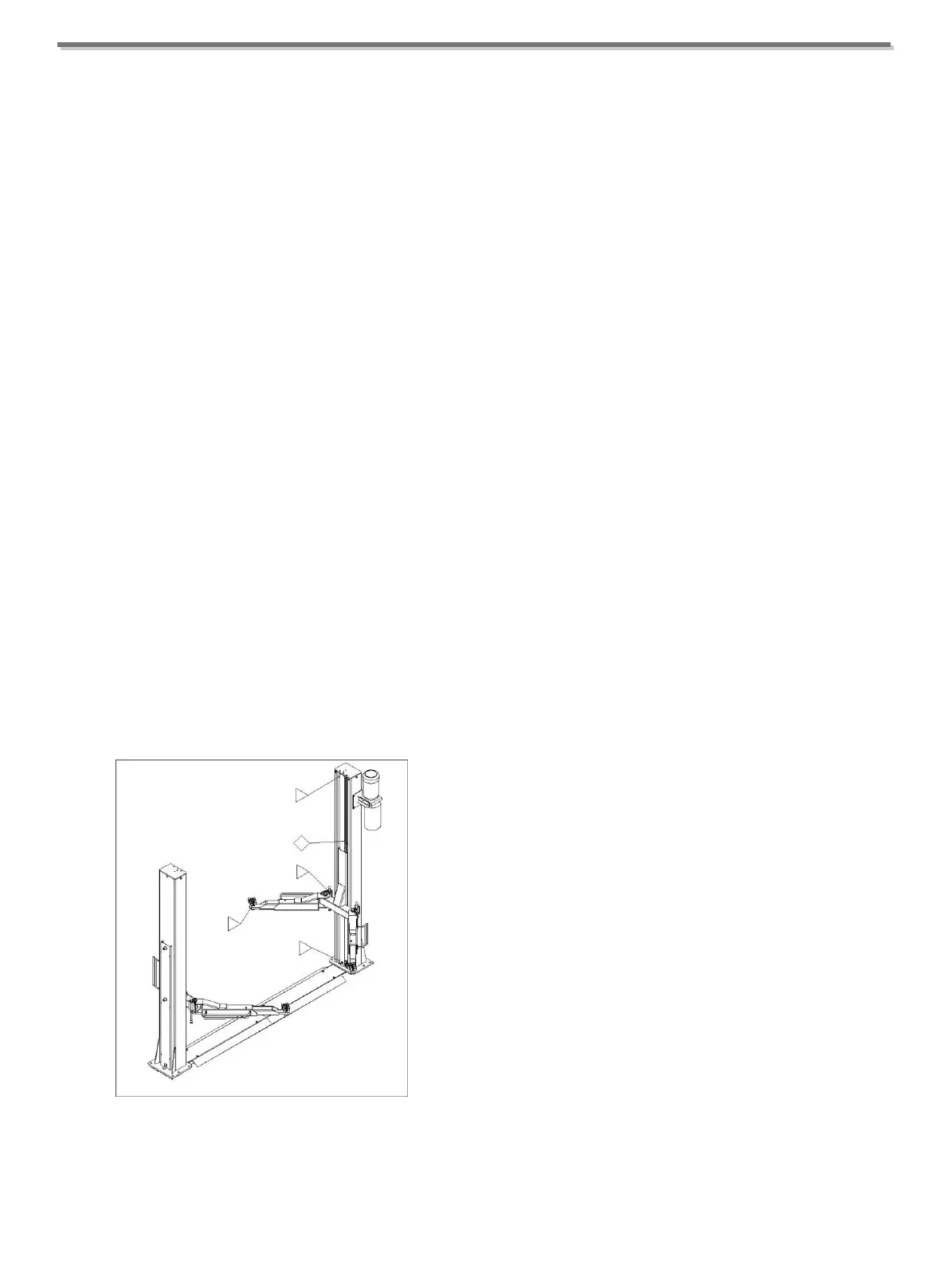

6.3 PERIODIC LUBRIFICATION CHART

Lubricate the rack as indicated in Fig. 40. Grease must be

taken from perfectly closed tins and/or well preserved. Old

or damaged grease may damage the lubricated part.

△ Lubricate every three months

□ Lubricate every six months

Fig. 40

Chapter 7 TROUBLESHOOTING

7.1 TROUBLESHOOTING GUIDE

Troubleshooting and possible repairs require absolute

compliance with ALL THE SAFETY PRECAUTIONS

indicated in Chapter 6 “MAINTENANCE” and Chapter 3

“SAFETY”.

7.2 POSSIBLE PROBLEMS AND SOLUTIONS

-19-

Loading...

Loading...