USER’S MANUAL

◆ Block the spring ring at the end of the pin.

WARNING

End-user should confirm that the over load device must

be connected before the electrical power connected to lift.

4.4.5 INSTALL THE COVER PLATE

Install the cover plates at the chassis by 4 pieces M8×16

bolts.

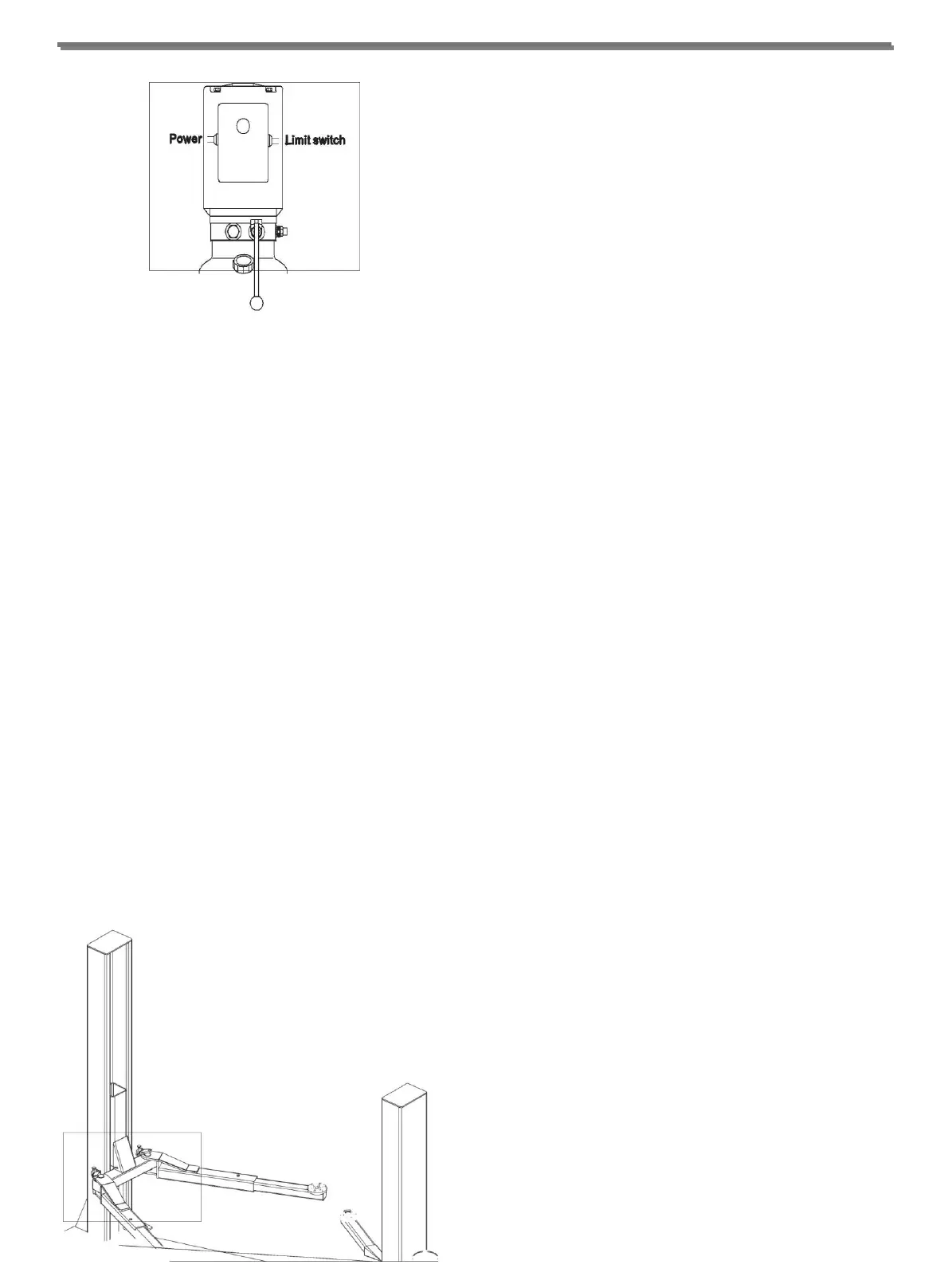

Fig. 35

4.4.3.3 The wires should be fixed by nylon pitch.

4.4.3.4 Close the cover of the junction box. Press the up

push button (Fig. 35), the motor rotation direction should

be the one shown by the arrow on the pump.

BEWARE: The pump rotating for a long time in the

wrong sense may cause itself serious damages.

4.4.3.5 Make sure that the post end limit switch work

properly by pressing them manually.

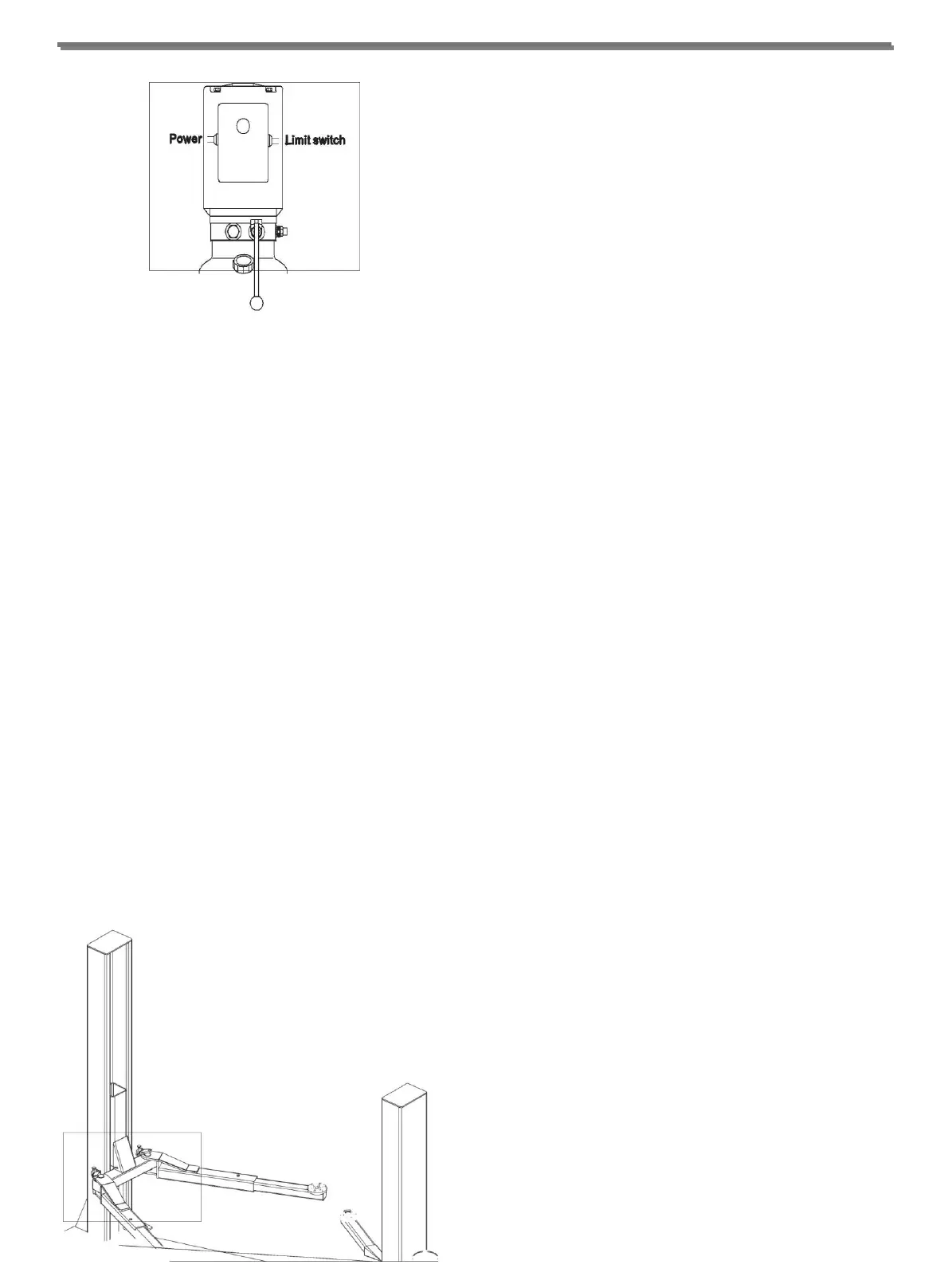

4.4.4 ARM ASSEMBLING

◆ Press the up push button, raise the carriages to a

height of about 70cm off the ground, then press the

manual lowering lever until the carriages rest on the

safety wedge. CUT OFF THE POWER SUPPLY TO

THE LIFT.

◆ Grease the holes φ40 on the arms ends.

◆ Mount the arms into the carriage supports and insert

the dowel pins into the support holes as shown in Fig.

36. Notice the entry of both arms is the same with the

entry of the vehicle.

Fig. 36

4.4.6 INSTALL SPRING SCREW

◆ Make 14 drills on the basement with a helical concrete

bit with a diameter of 18mm to a depth to 130mm.

Use the basis pad as a drilling template.

◆ Install the screw according to Fig. 29.

4.5 TESTING AND CHECKS TO PERFORM

BEFORE START-UP

4.5.1 MECHANIAL TESTS

◆ Attachment and tightness of bolts, fittings and

connections

◆ Free sliding of moving parts

◆ Clean state of various parts of the machine

◆ Position of the protection device

◆ Arms blocking device

4.5.2 ELECTRIC TESTS

◆ Connection comply with diagrams

◆ Machine earth connections

4.5.3 OPERATING OF THE FOLLOWING DEVICES

◆ Rise limit switch

◆ Manual lowering valve

4.5.4 HYDRAULIC OIL TEST

◆ Sufficient oil in the tank

◆ No leaks

-14-

Loading...

Loading...