USER’S MANUAL

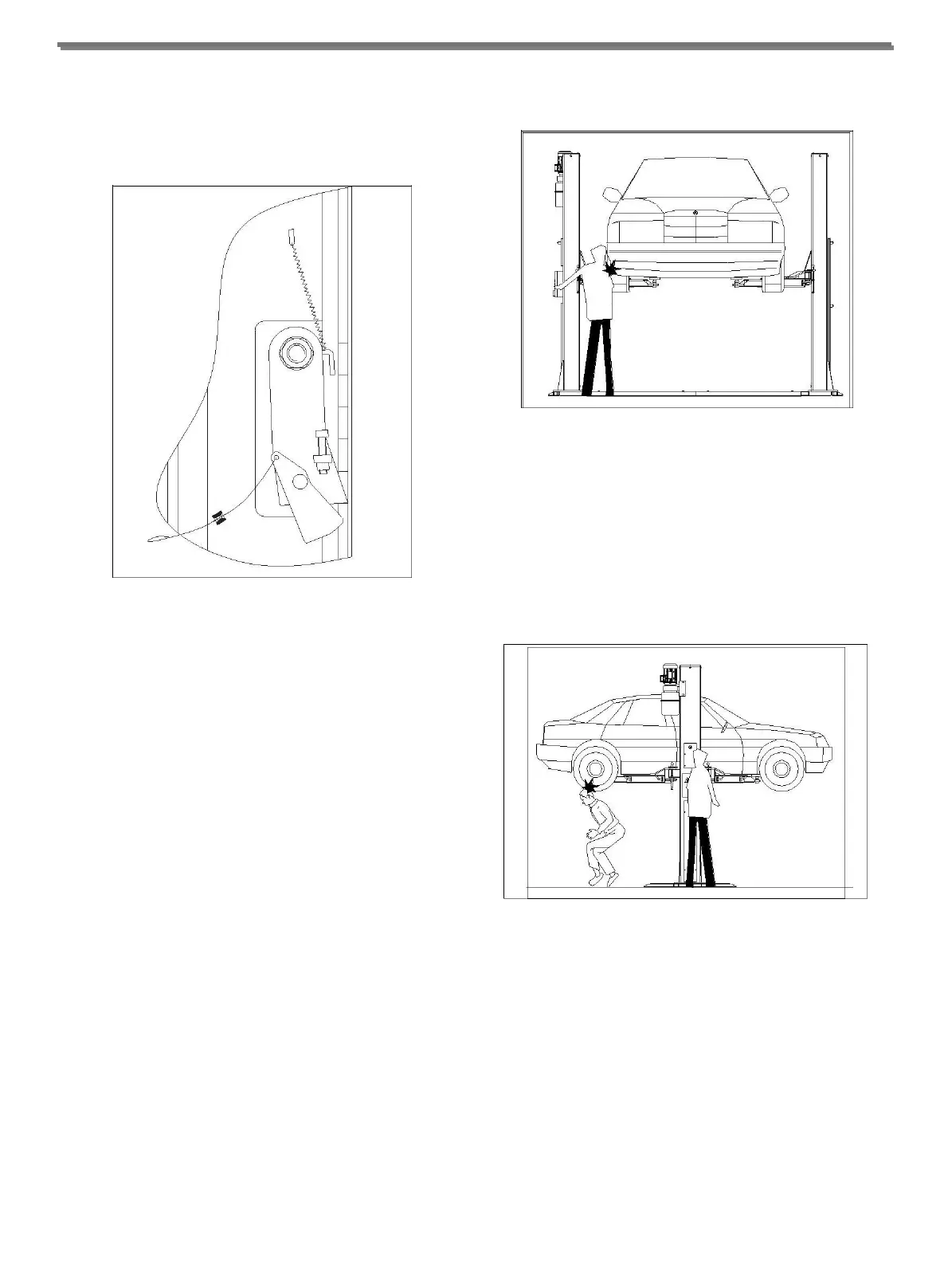

◆ If the hydraulic cylinder breaks, the safety wedges

will trip (Fig. 16), located inside the posts. The

wedges are pushed by the spring and immediately stop

the carriage preventing their descent.

structure. During this phase, the operator must remain in

the command zone. (Fig. 17)

Fig. 16

◆ If the moving part exceed its travel distance, on the

upper part of the command post there is one limit

switch and is usually set working by the “actuator”

(Fig. 14) on the command side carriage. If the first

limit switch did not work, the second one would trip

after 3sec of carriage run.

◆ In case of total breakdown of the limit switches, the

carriage will stop a few millimeter higher. Because the

hydraulic cylinders come to end stroke, will cause the

maximum pressure valve (on hydraulic unit) to trip.

Fig. 17

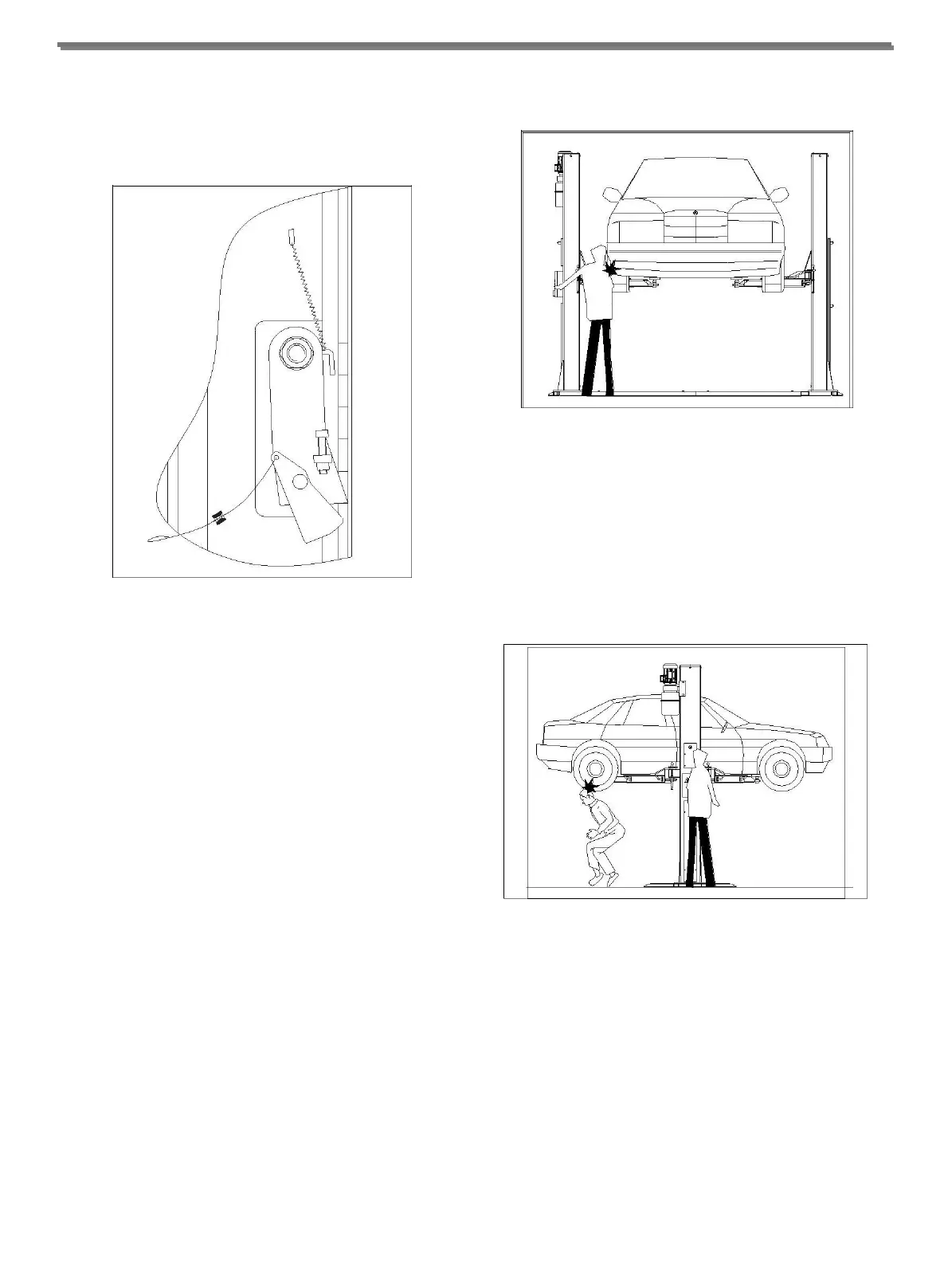

3.6.2 RISK OF CRUSHING (PERSONNEL)

When the platform and the vehicle are descending,

personnel are prohibited from entering the area beneath the

moving parts of the lift. (Fig. 18) The lift operator must not

start the maneuver until it has been clearly established that

there are no persons in potentially dangerous positions.

3.6 RISKS OF PERSONS

This paragraph illustrates risks to which the operator,

maintenance worker, or any person near the operating area

of the lift may be exposed in the case of impeccable use of

equipment.

3.6.1 RISK OF CRUSHING (OPEARATOR)

Possible if the operator controlling the lift is not in the

specified position at the command panel. When the

platform and the vehicle are descending, the operator must

never be partly or completely underneath the moving

Fig. 18

3.6.3 RISK OF IMPACT

Caused by the parts of the lift or the vehicle that are

positioned at head height. When, due to operational reasons,

the lift is immobilized at relatively low elevations (less

than 1.75m from the ground) personnel must be careful to

avoid impact with parts of the machine not marked with

special hazard coloring. (Fig. 19)

-8-

Loading...

Loading...