P. 74 - Chap. 10 Maintenance

G

B

Changing the oil

Change the oil at the frequency indicated in the scheduled maintenance table of paragraph 10.2 or when you

plan to use a different oil from that in the machine.

Carry out this operation when the oil is still warm so that its viscosity is low and fluidity high.

Caution: lubricant temperature must not be sufficient to cause burns.

Proceed as follows:

Remove the front panel PF using the

key provided

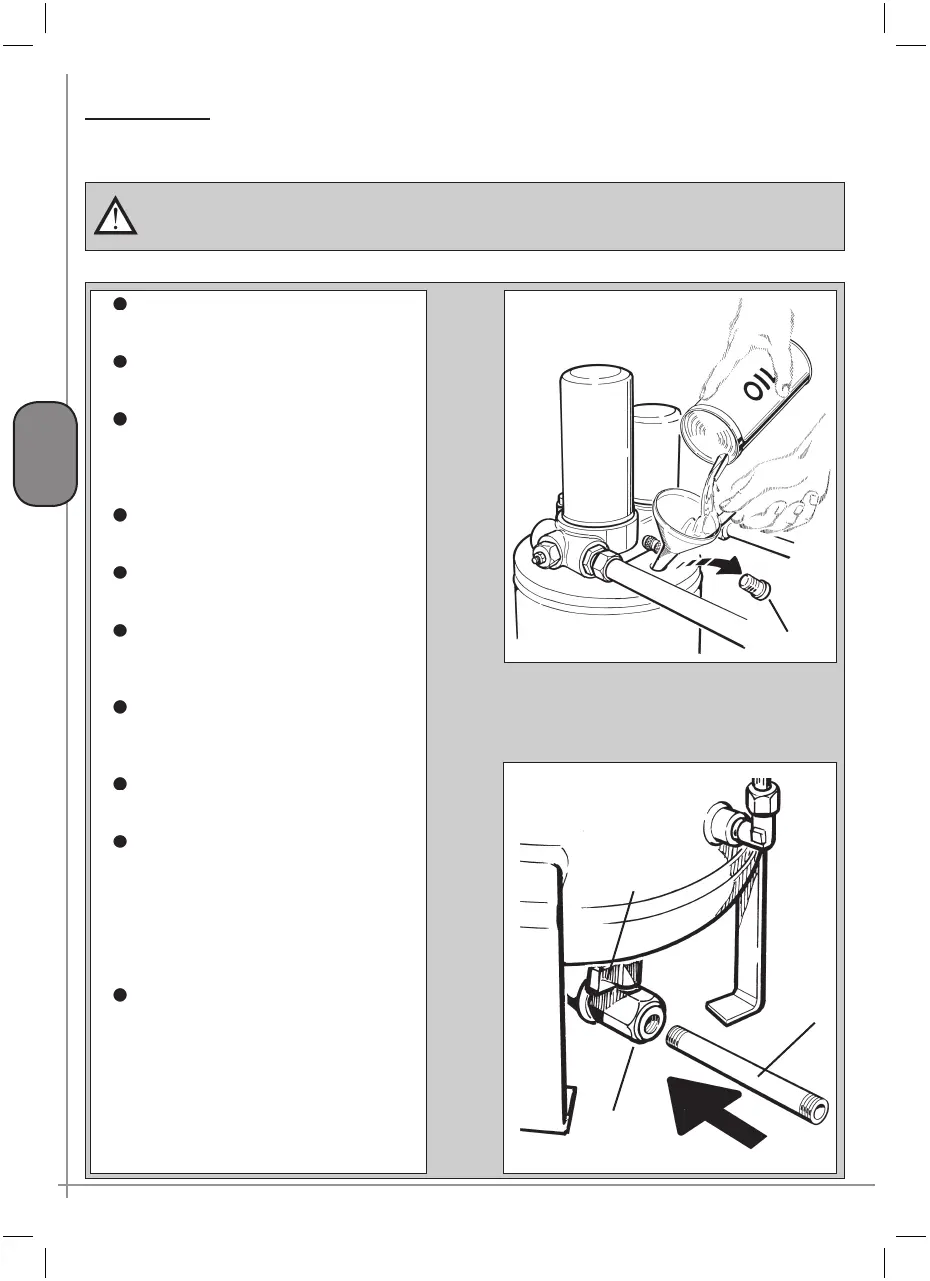

Loosen oil filler plug TO. Be careful not

to lose the seal (Fig. 43)

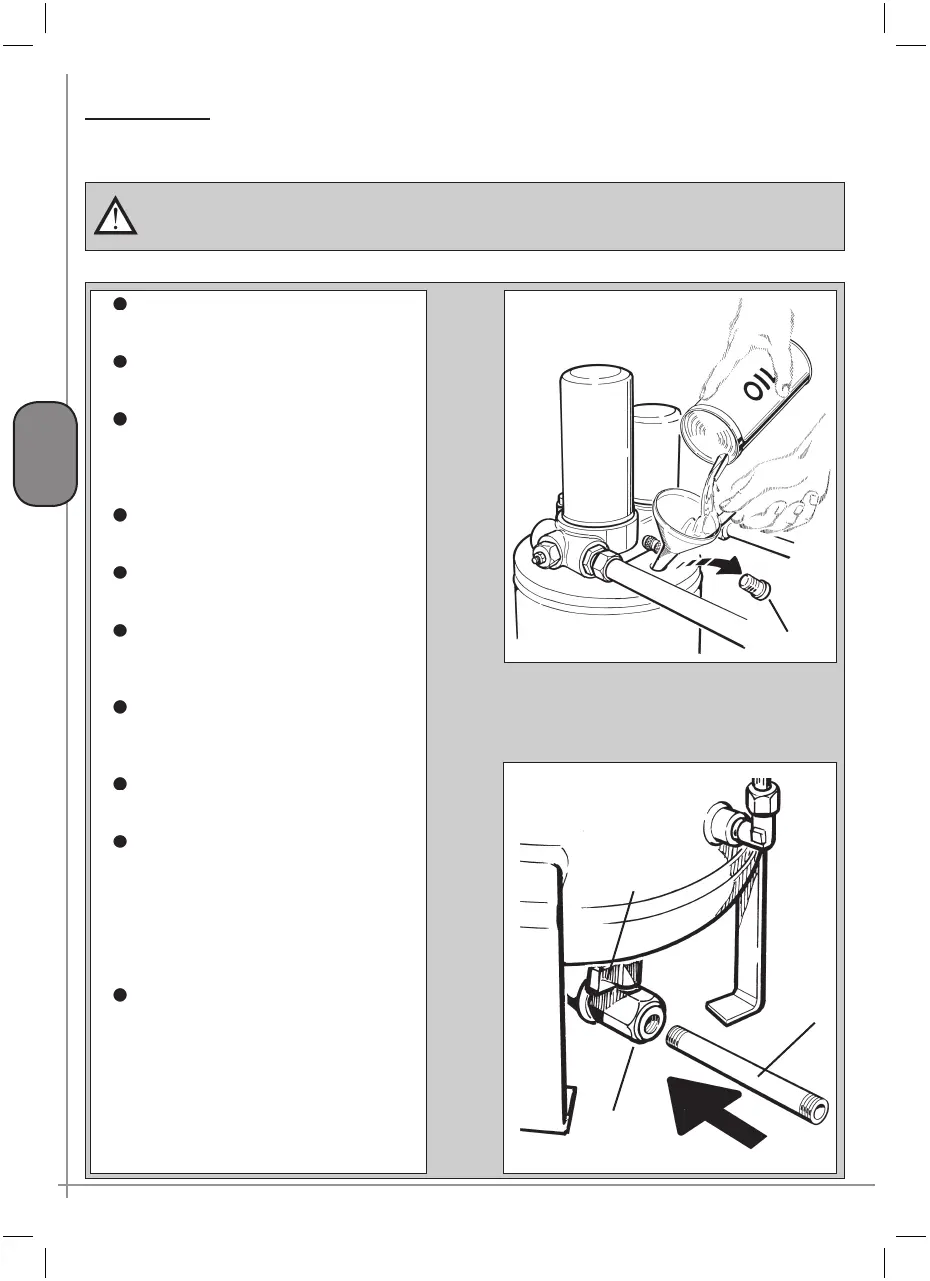

Connect fitting R provided, which must

communicate with a suitable collection

recipient, to fitting

DO after unscrewing

the safety plug (Fig. 44)

Open drain valve RSO and drain the

lubricant (Fig. 44)

After draining, close oil drain valve

RSO

Refill with oil as described in the “Check-

ing oil level/topping up” paragraph

(Fig. 43)

Check that the seal of plug TO is cor-

rectly positioned and fasten the plug (not

too tightly)

Replace the front panel PF using the key

provided

Open the shut-off valve between the

compressor and the distribution line.

Switch the circuit breaker on and carry

out a test start-up.

Let the compressor run for a few minutes

and then make a visual inspection for

any oil leaks

Check the oil level again as indicated

in the “Checking oil level/topping up

”

and if necessary top up

Fig. 43

Fig. 44

TO

R

DO

RSO

Loading...

Loading...