27

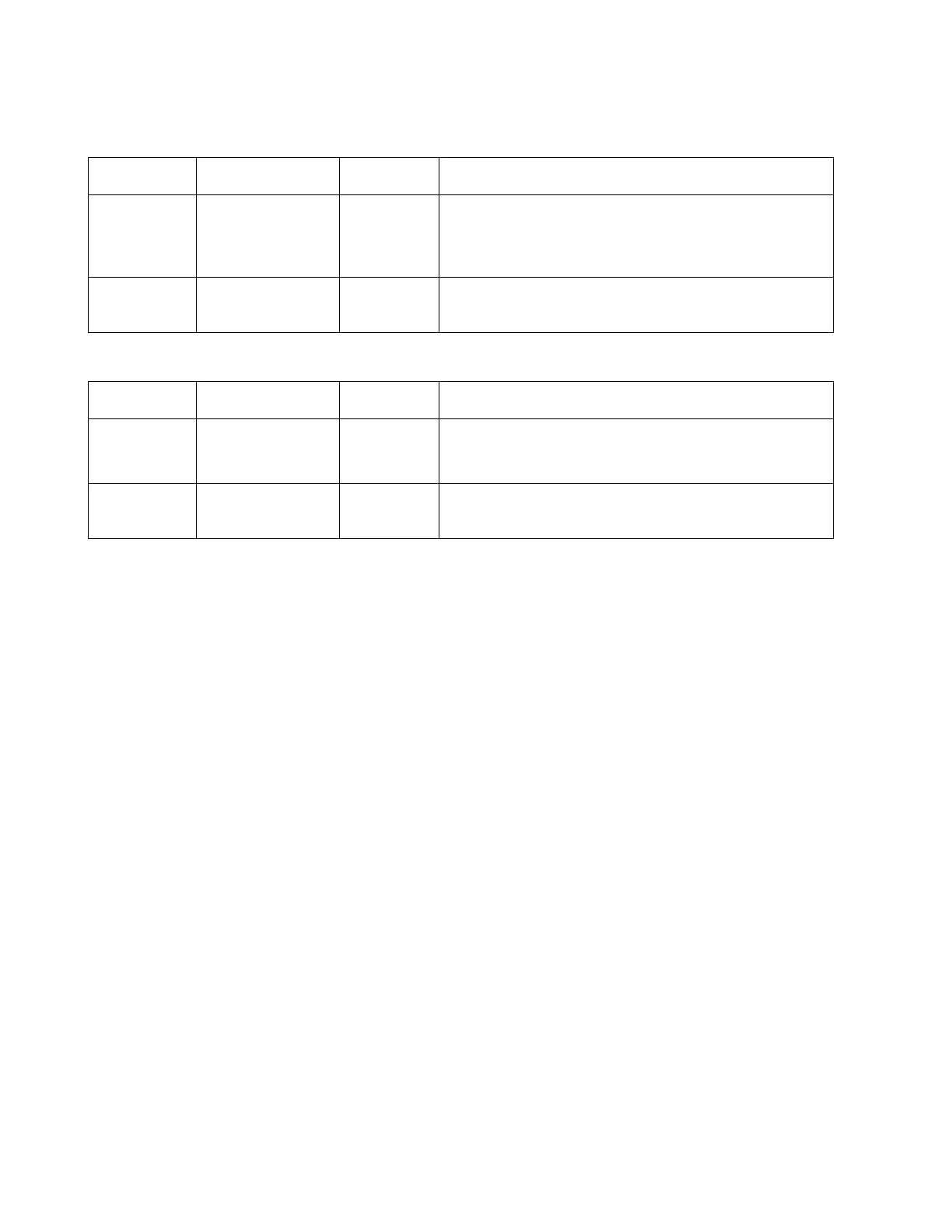

ACS580 More parameters read from drive to PLC (optional)

Actual value or

parameter of drive

GG = parameter group, ii = parameter index

Example, 0107 = actual current; 3501 = motor est.

temp

Updates fieldbus settings (groups 50 to 57)

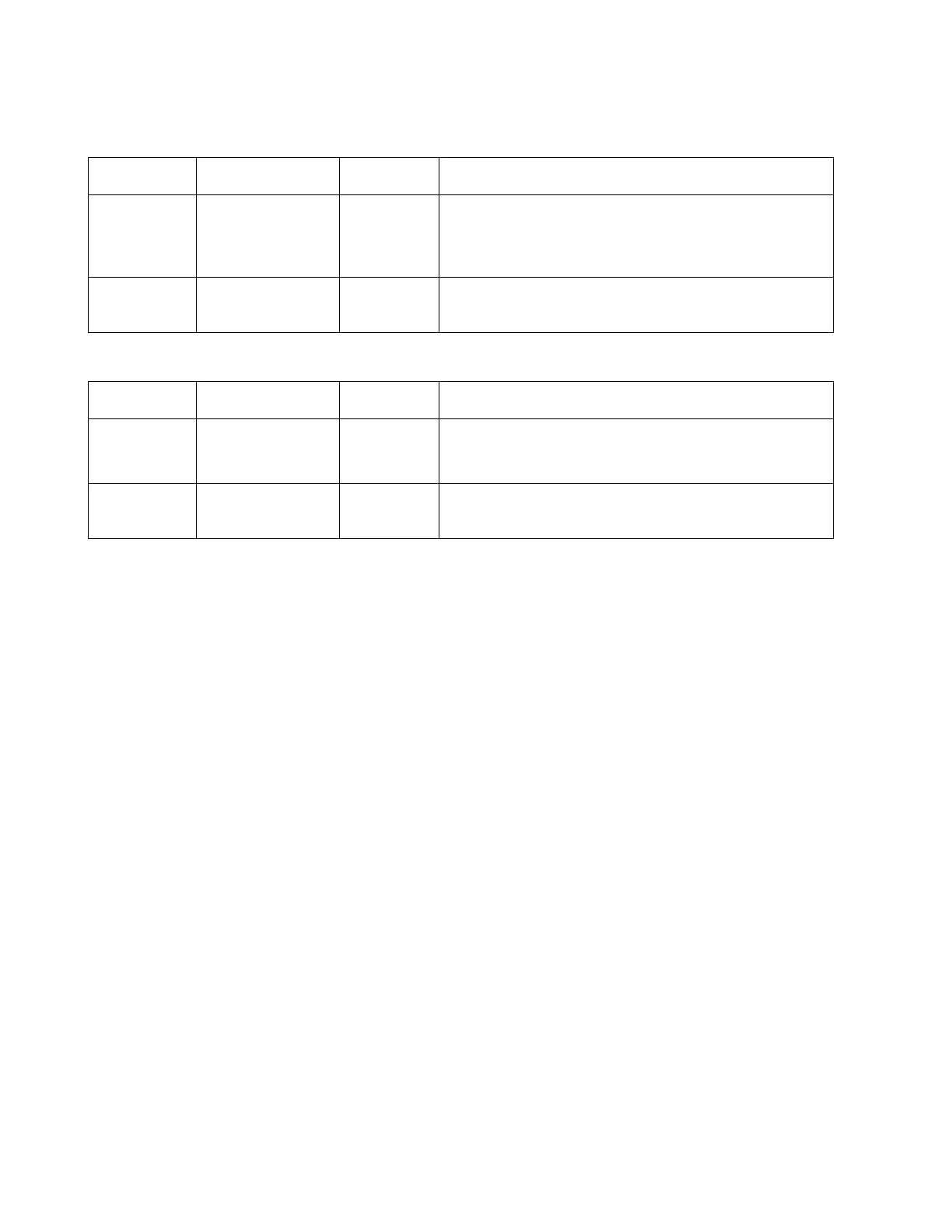

ACS580 More parameters written from PLC to drive (optional)

GG = parameter group, ii = parameter index

Example, 2312 = acceleration time 1

Updates fieldbus settings (groups 50 to 57)

Configuring ACS800 drives

Starting ACS800 drives for PROFIBUS DP

1. Power up the drive.

2. Enable the communication between the adapter module and the drive by setting parameter 98.02

COMM. MODULE LINK to FIELDBUS.

3. Set the RPBA-01 configuration parameters in group 51. At the minimum, set the required node

address in parameter 51.02.

4. With parameter 30.18 COMM FLT FUNC, select how the drive reacts to a fieldbus communication

break.

5. With parameter 30.19 MAIN REF DS T-OUT, define the time between communication break detection

and the selected action.

6. Define the process data transferred to and from the drive in the RPBA-01 configuration parameter

group 51.

Note: The Status Word, Actual Speed, Control Word and Speed Reference are configured as default.

7. Validate the settings made in parameter group 51 by setting parameter 51.27 FBA PAR REFRESH to

REFRESH.

8. Set the relevant drive control parameters to control the drive according to the application.

Loading...

Loading...