ControlMaster CM30 and CM50

Universal process controllers,

1

/4 and

1

/2 DIN 8 Templates and Functionality

IM/CM/ED–EN Rev. B 69

8.3.3 Cascade with Feedforward

This template connects 2 PID loops together in order to enhance the control of a Master variable (loop) by

manipulation of a slave loop. The first (master) controller provides the set point for the second (slave)

Controller. The 2 controllers are linked internally.

To the Master output a feedforward signal is added. This signal is a disturbance variable which is weighted

by the feedforward ratio and bias values. . When the auto/manual mode is changed via the front panel or by

a digital signal both the master and slave controllers change mode, the slave setpoint can then be adjusted

from the front panel, and this value is then tracked by the Master controller (taking account of the

feedforward signal) to ensure a bumpless transfer back into auto mode.

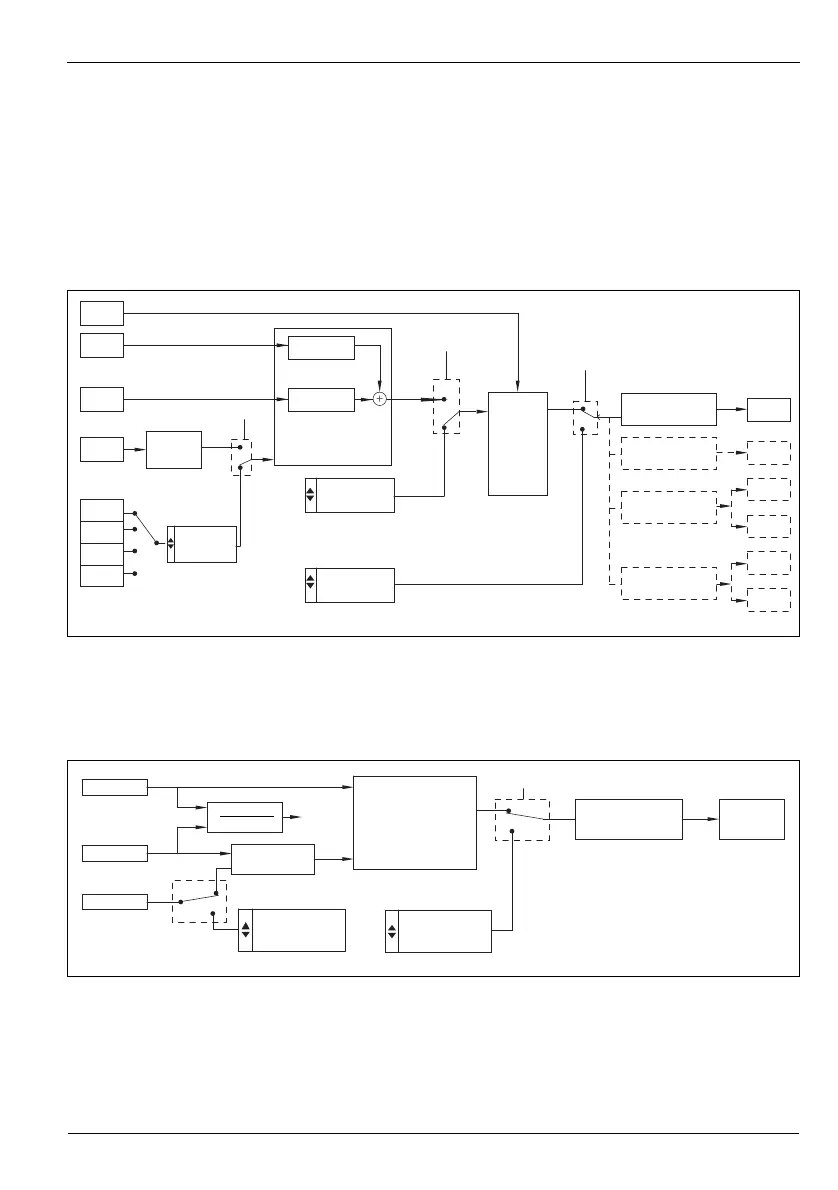

8.3.4 Ratio Controller (Internal / External Ratio)

The ratio controller template configures the ControlMaster to regulate one process variable against another

based on a specified ratio. The unregulated variable or 'wild' variable is weighted by ratio and bias values

and this forms the control setpoint for the process variable. The ratio value applied to the wild variable can

either be a local value set on the front panel or a remote signal on an analog input.

A/M

DV

L/R

MSP

AIN 1

AIN 2

x Ratio

+ Bias

LSPT1

LSPT2

LSPT3

LSPT4

Local

Set Point

Local

Set Point

Loop 1 PID

Control (Master)

PID

O/P

2

OP

Time Prop

Output

Motorized

Valve

Split

Output

AO1

RLY1

RLY2

RLY1

OP2

OP1

Output Type

Analog

Output

Manual

Output

MPV

SSP

LR

SPV

Loop 2

PID

Control

(Slave)

AIN 4

AIN 3*

x FF Gain

*Source can be changed in Control / FeedForward configuration – see Section 7.4, page 36

RSP

PID

PID

O/P 1

AIN 1

AIN 2

AIN 3

Local

Ratio

Manual

Output

A/M

OP

PID

O/P

Loop1

PID Control

PV

S

P

Analog

Output

Output Type

AO1

PV – Bias

WV

WV

WV x Ratio

+ Bias

A

c

t

u

a

l

R

a

t

i

o

Loading...

Loading...