128

FEM630 | ELECTROMAGNETIC FLOWMETER | OI/FEM630-EN REV. A

...11 Repair

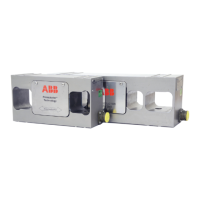

Replacing the sensor

If the O-ring gasket is seated incorrectly or damaged,

this may have an adverse effect on the housing

protection class.

Follow the instructions in Opening and closing the

housing on page 22 to open and close the housing

safely.

NOTICE

Note

The frontend board of the replacement sensor has a

SensorMemory module. The calibration and system data of

the sensor is stored in the SensorMemory. After

powering-up the power supply, the transmitter

automatically replicates the system data from the

SensorMemory.

Replace the sensor as described below:

1 Switch off the power supply.

2 Unscrew / remove the cover.

3 Disconnect the signal cable (if necessary, remove the

potting compound).

4 Install the new sensor in accordance with Installation on

page 14.

5 Complete the electrical connection in accordance with

Electrical connections on page 28.

6 Unscrew / set down the cover once again

7 After powering-up the power supply, the transmitter

automatically replicates the system data from the

SensorMemory.

Returning devices

Use the original packaging or a secure transport container

of an appropriate type if you need to return the device for

repair or recalibration purposes.

Fill out the return form (see Return form on page 135) and

include this with the device.

In accordance with the EU Directive governing hazardous

materials, the owner of hazardous waste is responsible for

its disposal or must observe the following regulations for

shipping purposes:

All devices delivered to ABB must be free from any

hazardous materials (acids, alkalis, solvents, etc.).

Address for returns:

Please contact Customer Center Service according to page 6

for nearest service location.

WARNING

Risk of injury due to process conditions.

The process conditions, for example high pressures and

temperatures, toxic and aggressive measuring media,

can give rise to hazards when working on the device.

• Before working on the device, make sure that the

process conditions do not pose any hazards.

• If necessary, wear suited personal protective

equipment when working on the device.

• Depressurize and empty the device / piping, allow to

cool and purge if necessary.

Loading...

Loading...