20

FEM630 | ELECTROMAGNETIC FLOWMETER | OI/FEM630-EN REV. A

5 ...Installation

Installing the sensor

Damage to the device

Damage to the device due to improper assembly.

• The use of graphite with the flange or process

connection gaskets is prohibited. This is because, in

some instances, an electrically conductive coating

may form on the inside of the meter tube.

• Vacuum shocks in the piping should be avoided to

prevent damage to the liners. Vacuum shocks can

destroy the device.

NOTICE

The flowmeter sensor can be installed at any location in the

piping while taking the installation conditions into account.

1 Remove protective plates, if present, to the right and left

of the meter tube. To prevent possible leakage, make

sure that the liner on the flange is not cut or damaged.

2 Position the flowmeter sensor plane parallel and

centered between the piping.

3 Use the appropriate screws for the holes in

accordance with Torque information on page

136.

4 Slightly grease the threaded nuts.

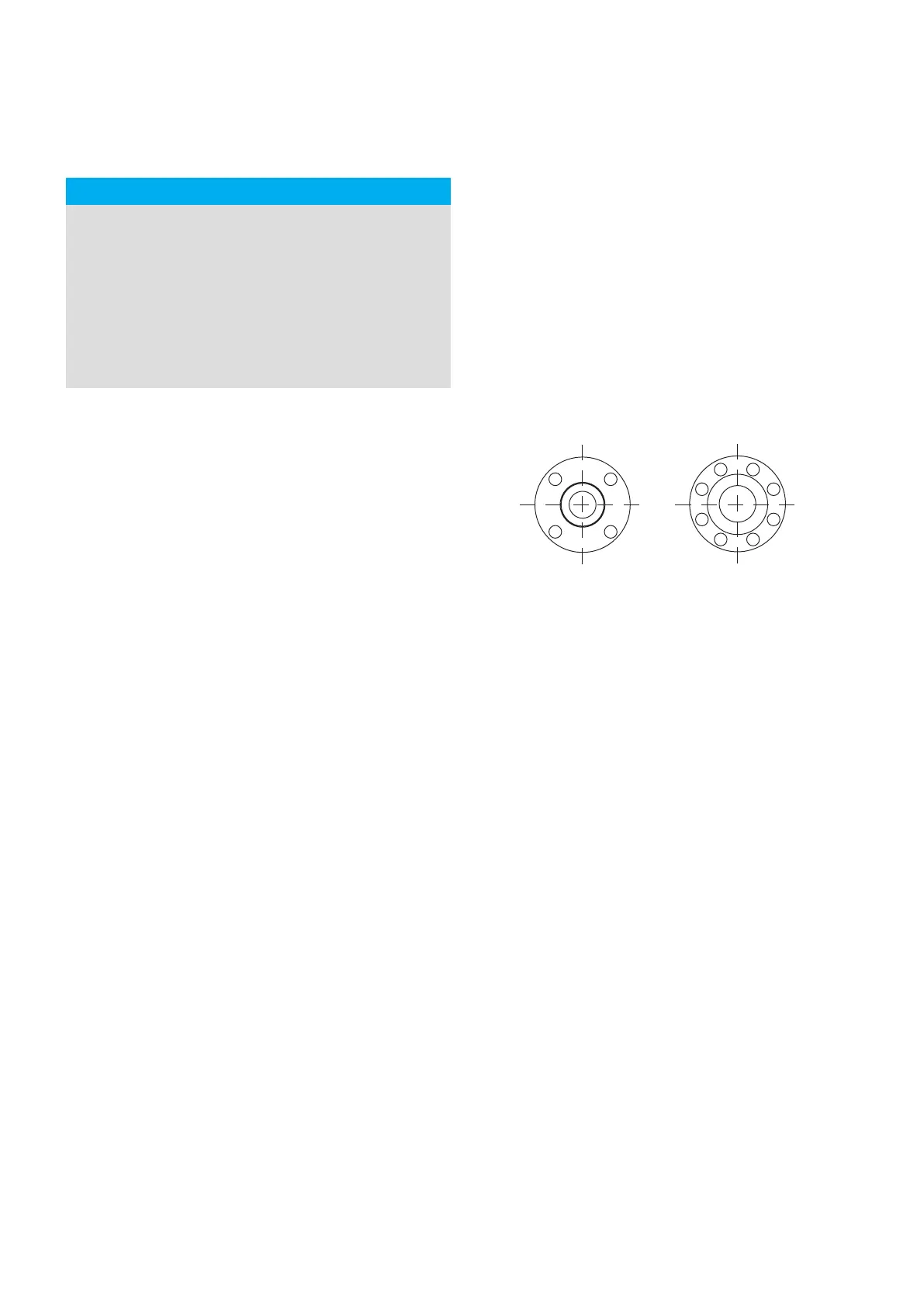

5 Tighten the nuts in a crosswise manner as shown

in the figure. Observe the tightening torques in

accordance with Torque information on page

time to the maximum torque. Do not exceed the

max. torque.

Figure 18 Tightening sequence for the flange screws

G11726

1

2

7

8

5

3

4

6

1

2

3

4

Loading...

Loading...