VortexMaster FSV430, FSV450 SwirlMaster FSS430, FSS450 | CI/FSV/FSS/430/450-EN Rev. G 27

3. Use the appropriate screws for the holes.

4. Slightly grease the threaded nuts.

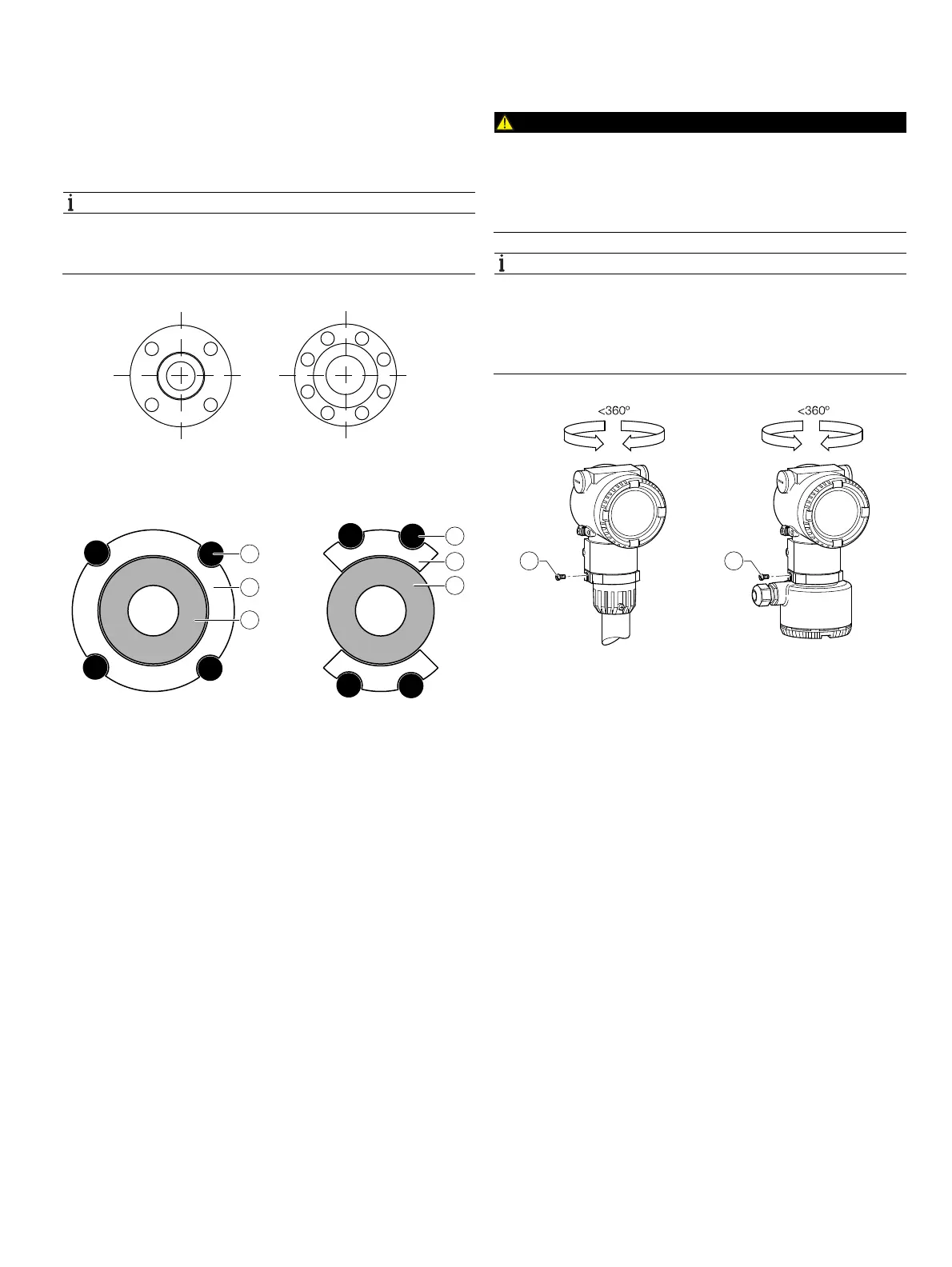

5. Tighten the nuts in a crosswise manner as shown in the

figure. First tighten the nuts to approx. 50 % of the

maximum torque, then to 80 %, and finally a third time to

the maximum torque.

NOTICE

Torques for screws depend on temperature, pressure, screw

and gasket materials. The relevant applicable regulations

must be taken into consideration.

Fig. 24: Tightening sequence for the flange screws

5.4.1 Centering the wafer type design

Fig. 25: Centering the wafer type design with the ring or segment

1 Bolt 2 Centering ring 3 Meter tube (wafer type)

4 Centering segment

Wafer type devices (FV400 only) are centered via the outside

diameter of the flowmeter sensor body with the corresponding

bolts.

Depending on the nominal pressure rating, sleeves for the

bolts, a centering ring (up to DN 80 [3"]) or segments can be

ordered as additional accessories.

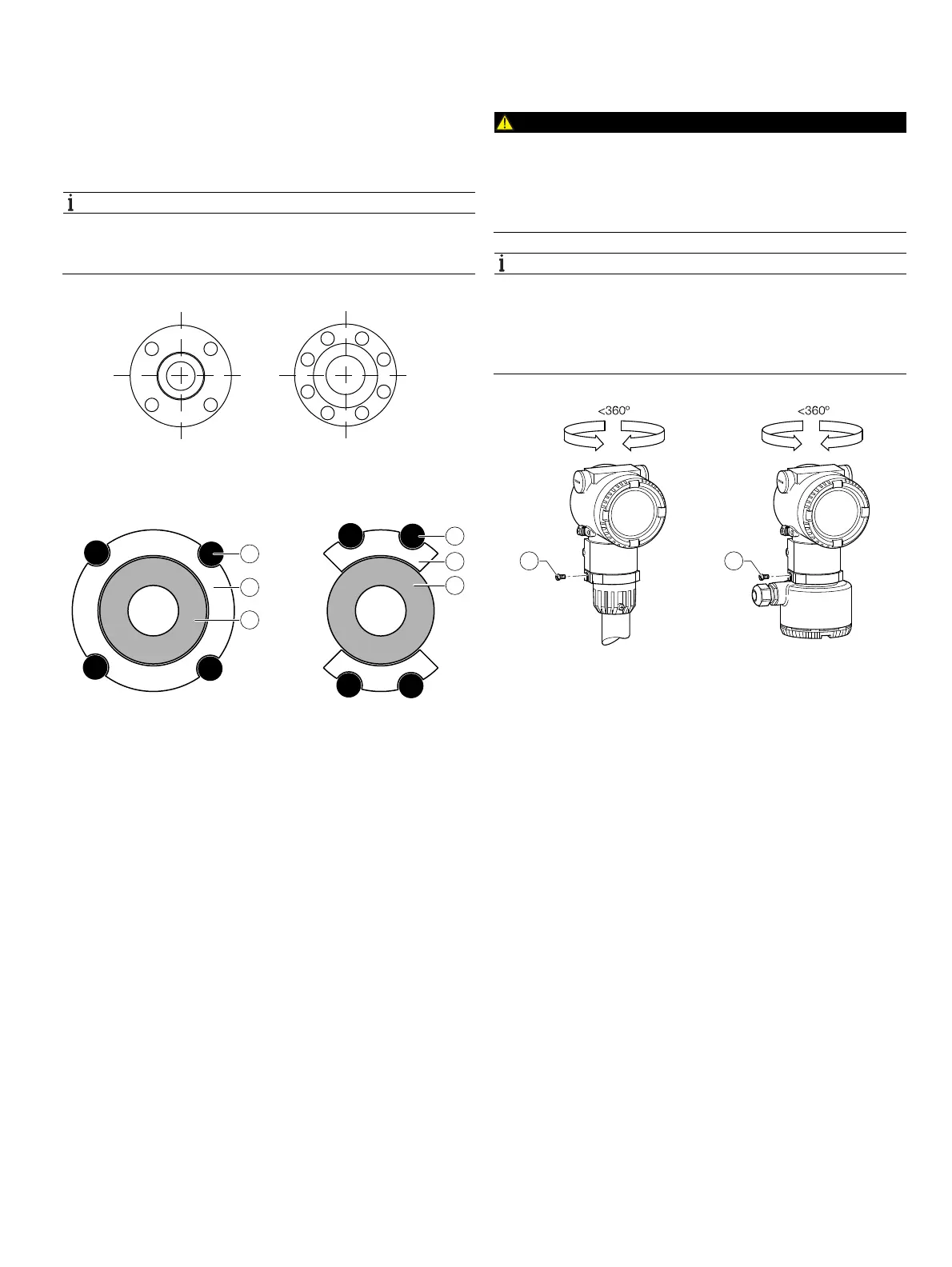

5.4.2 Adjusting the transmitter position

Rotating the transmitter housing

DANGER

Risk of explosion!

When the screws for the transmitter housing are loosened,

the explosion protection is suspended.

Tighten all screws for the transmitter housing prior to

commissioning.

NOTICE

Damage to components!

— The transmitter housing must not be lifted without pulling

out the cable, otherwise the cable can tear off

— The transmitter housing must not be rotated more than

360 degrees

Fig. 26: Rotating the transmitter housing

1 Locking screw

1. Unscrew the locking screw on the transmitter housing with

a 4 mm Allen key.

2. Rotate the transmitter housing in the direction required.

3. Tighten the locking screw.

G11726

1

2

7

8

5

3

4

6

1

2

3

4

G11763

1

2

3

1

4

3

G11764

11

Loading...

Loading...